Special Reports

2016 Quarter 3 Issue 28

Shini Central Granulator—Regular & Budget Series

Regular Series

Regular Series of Central Granulator SG-B is a new model that derived by SG-43/50/70 series which aims to meet the market demand. There are models of SG-43B/50B/70B for selection. Compared to standard model, it doesn’t have soundproof box and feeding blower, but has the same performance and is cheaper.

Regular Series of Central Granulator SG-B is a new model that derived by SG-43/50/70 series which aims to meet the market demand. There are models of SG-43B/50B/70B for selection. Compared to standard model, it doesn’t have soundproof box and feeding blower, but has the same performance and is cheaper.

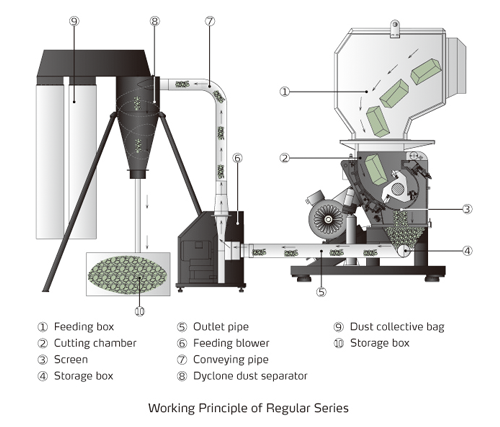

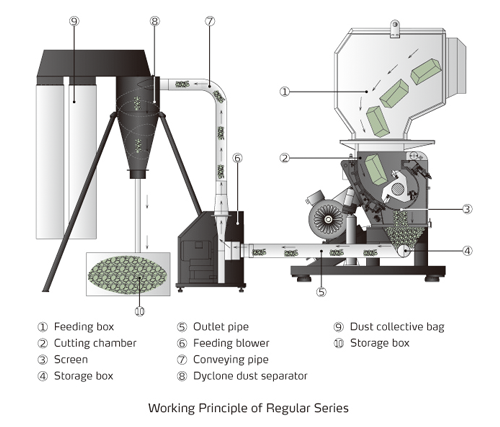

Working Principle of Granulator

Put the material into cutting chamber via the feed box, then motor drives the blade rest shaft rotating. The material will be granulated by rotating blade and fixed blade. The granule size is determined by screen diameter, which is below the cutting chamber. After granules drop to the collective box through screen, they are conveyed to the feeding blower by outlet pipe. Via feeding pipe, the blower will feed granules to cyclone separator for processing. Then the powder will be sent to dust collective bag, the granules will be sent to the storage box.

Regular Series of Central Granulator is applicable to granulate variety of plastic materials, including rejects of injection molding, blow molding or extrusion process. The series adopts sound-proof feeding box which is opened and closed by electronic handspike to ensure safe operation. High-rigidity and wearable cutter combined with V-type cutting technology makes efficient cutting and low noise. The rear plate of cutting chamber works with cooling water device, which greatly decreases the temperature in cutting chamber and avoids conglutinated granules.

Options

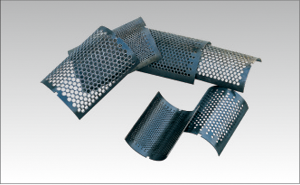

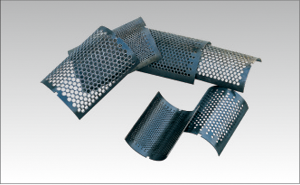

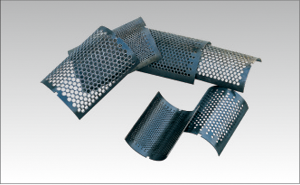

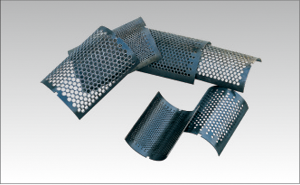

Optional screen mesh size includesΦ 8 Φ10 Φ14 Φ17 Φ25 which can meet different production requirement. Add “SS” at the end of the model code.

Optional presetting knife jig: the easy of cutting installing and adjusting technology enables rotating blades can be adjusted in the fixture outside the machine instead of machine inside. Add “KAD” at the end of the model code.

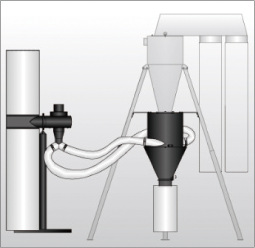

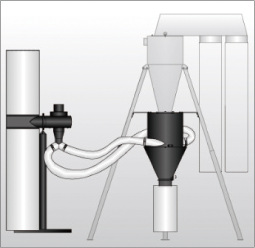

Optional conveying blower: Separately convey the granules to cyclone separator via blower. Add “SC” at the end of the model code.

Optional dust-separating system is used to remove dust in the material. Add “DS” at the end of the model code.

Optional flywheel: increase inertia, thereby increasing the cutting ability. At the same time can result in a more balanced force and longer service life. Add “FW” at the end of the model code.

When granulating fibers reinforced plastics or materials, it adds fiber handling series of Granulator. Adopt hardening treatment for cutting chamber and material contacted surface. Cutter material is made of V-4E and S50C; Add “F” at the end of the model code.

Budget Series

The Budget Series of Granulator SG-EB is the new model designed for customer with simple applications. There are models of SG-2130EB/2540EB/2950EB/3260EB for selection. The series is cost-effective and with high performance-price ratio. Compared to standard model, it doesn’t have soundproof box and feeding blower, but has same performance and is cheaper.

The Budget Series of Granulator SG-EB is the new model designed for customer with simple applications. There are models of SG-2130EB/2540EB/2950EB/3260EB for selection. The series is cost-effective and with high performance-price ratio. Compared to standard model, it doesn’t have soundproof box and feeding blower, but has same performance and is cheaper.

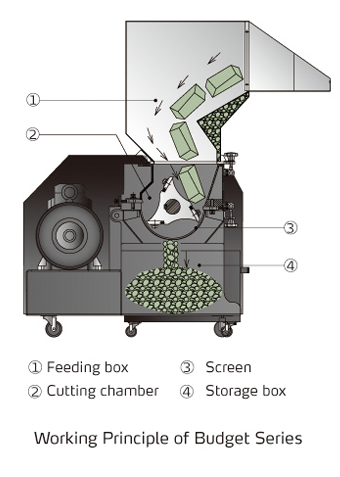

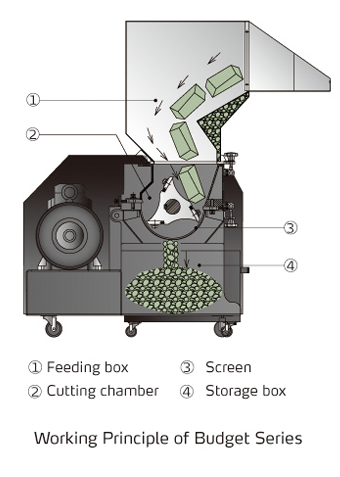

Working Principle of Granulator

Put the material into cutting chamber via the feed box, then motor drives the blade rest shaft rotating. The material will be granulated by rotating blade and fixed blade. The granule size is determined by screen diameter, which is below the cutting chamber, and the granules will be sent to the recycler.

Working Principle of Granulator

Put the material into cutting chamber via the feed box, then motor drives the blade rest shaft rotating. The material will be granulated by rotating blade and fixed blade. The granule size is determined by screen diameter, which is below the cutting chamber. After granules drop to the collective box through screen, they are conveyed to the feeding blower by outlet pipe. Via feeding pipe, the blower will feed granules to cyclone separator for processing. Then the powder will be sent to dust collective bag, the granules will be sent to the storage box.

Regular Series of Central Granulator is applicable to granulate variety of plastic materials, including rejects of injection molding, blow molding or extrusion process. The series adopts sound-proof feeding box which is opened and closed by electronic handspike to ensure safe operation. High-rigidity and wearable cutter combined with V-type cutting technology makes efficient cutting and low noise. The rear plate of cutting chamber works with cooling water device, which greatly decreases the temperature in cutting chamber and avoids conglutinated granules.

Options

Optional screen mesh size includesΦ 8 Φ10 Φ14 Φ17 Φ25 which can meet different production requirement. Add “SS” at the end of the model code.

Optional dust-separating system is used to remove dust in the material. Add “DS” at the end of the model code.

When granulating fibers reinforced plastics or materials, it adds fiber handling series of Granulator. Adopt hardening treatment for cutting chamber and material contacted surface. Cutter material is made of V-4E and S50C; Add “F” at the end of the model code.

Budget Series

Working Principle of Granulator

Budge Series of Central Granulator has optimized structure which is safe, reliable and cost effective. It is applicable to granulate various plastic materials including rejects from injection molding, blowing molding and for central granulating. It is the budge series that can reduce parts cost; monolayer feeding box. Staggered blades design can decentralize working load when granulating to increase cutting efficiency. The welded cutting chamber ensures wear-ability and high rigidity. Adopt adjustable bearing with base mounted outside side-plate of cutting chamber, which is easy for bearing installation and maintenance.

Option

Optional screen mesh size includes Φ6 Φ10 Φ12 which can meet different production requirement. Add “SS” at the end of the model code.

Optional stainless-steel feed throat and storage box. Add “R” at the end of the model code.

When granulating fiber reinforced plastics or materials, it adds fiber handling series of Granulator. Adopt hardening treatment for cutting chamber and material contacted surface. Cutter material is made of V-4E and S50C; Add “F” at the end of the model code.

Option

Optional screen mesh size includes Φ6 Φ10 Φ12 which can meet different production requirement. Add “SS” at the end of the model code.

Optional stainless-steel feed throat and storage box. Add “R” at the end of the model code.

When granulating fiber reinforced plastics or materials, it adds fiber handling series of Granulator. Adopt hardening treatment for cutting chamber and material contacted surface. Cutter material is made of V-4E and S50C; Add “F” at the end of the model code.

Special Reports

- sLink --Protocol Solution

- MES Intelligent Manufacturing Integrated System

- Exhibition News of Chinaplas2016

- Introduction of Gram-meter Control System

If you want to read other articles, back to2016 Quarter 3 Issue 28.