Experience Sharing

2016 Quarter 4 Issue 29

Case Studies -- Shini Automation Application in Food Industry

China has 9 more years toward its goal of ‘Made in China 2025’, and manufacturers need to focus on improving production efficiency, maximizing machine utilization rate and upgrading automation level to catch up. Nowadays, automation has become the main stream for manufacturers seeking to gain more competitive edge. Take food industry for example, this industry has higher hygiene standard than other industries. Adopting more automation will not only increase productivity, but also avoid pollution and achieve food-grade hygiene requirements.

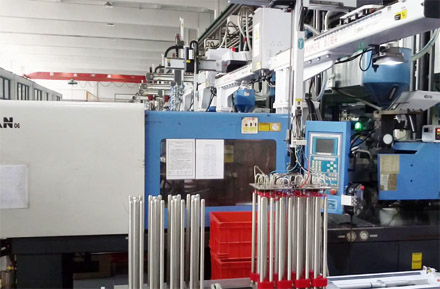

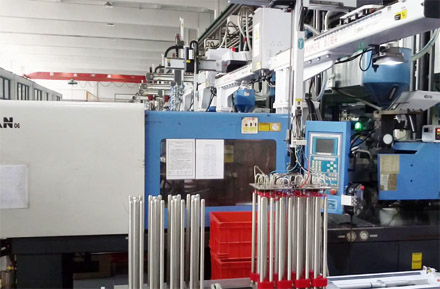

In our daily life, bottled drinking water is one of the most commonly known plastic products. Its body, cap and handle are all made of plastic materials. A plastic products manufacturer in Changzhou, Jaingsu province, mainly producing plastic caps and handles is supplying its products to renowned enterprises like Nongfuspring, C’estbon, etc., and has purchased 10 traverse robots from SHINI for taking out plastic caps and holders from injection molding machines. Other than the robots, SHINI also provide the customer with 2-station plastic handle collection fixtures which allow them to stack the handles to certain height after taking out from IMMs and enable easy packing. By adopting SHINI automation solutions, the company got its most time consuming and labor intensive work automatically and efficiently completed, and the manpower required is minimized. After the successful automation solutions, the customer also requested more such solutions from SHINI.

From the case above, we know that integrated automation solutions are vitally important for enterprises to upgrade their overall performance and enhance their competitiveness, and standalone automation equipment may not be enough for serving such purposes. SHINI automation business department has been working toward providing the best integrated automation solutions to our customers, instead of supplying only standalone equipment. And we are ready to help our customers realize the goal of ‘Made in China 2025’.

Shini full servo driven robots allow customers to choose single-arm or double-arm and single-stage arm or telescopic-arm for applications in 2-plate mold, 3-plate mold and hot-runner mold system. All full servo driven robots are capable of arranging, stacking, quality checking, insert-loading and other applications, and are suitable for injection molding machine under 3600T clamping force.

In our daily life, bottled drinking water is one of the most commonly known plastic products. Its body, cap and handle are all made of plastic materials. A plastic products manufacturer in Changzhou, Jaingsu province, mainly producing plastic caps and handles is supplying its products to renowned enterprises like Nongfuspring, C’estbon, etc., and has purchased 10 traverse robots from SHINI for taking out plastic caps and holders from injection molding machines. Other than the robots, SHINI also provide the customer with 2-station plastic handle collection fixtures which allow them to stack the handles to certain height after taking out from IMMs and enable easy packing. By adopting SHINI automation solutions, the company got its most time consuming and labor intensive work automatically and efficiently completed, and the manpower required is minimized. After the successful automation solutions, the customer also requested more such solutions from SHINI.

From the case above, we know that integrated automation solutions are vitally important for enterprises to upgrade their overall performance and enhance their competitiveness, and standalone automation equipment may not be enough for serving such purposes. SHINI automation business department has been working toward providing the best integrated automation solutions to our customers, instead of supplying only standalone equipment. And we are ready to help our customers realize the goal of ‘Made in China 2025’.

Shini full servo driven robots allow customers to choose single-arm or double-arm and single-stage arm or telescopic-arm for applications in 2-plate mold, 3-plate mold and hot-runner mold system. All full servo driven robots are capable of arranging, stacking, quality checking, insert-loading and other applications, and are suitable for injection molding machine under 3600T clamping force.

Experience Sharing

- STM and Extruder Integrated Control

- Case Sharing of Central Conveying System

- Central Conveying System Facilitates Enterprise’s Transformation and Upgrading

- Shini Modular Dryer Used in Pelletizing Industry

If you want to read other articles, back to2016 Quarter 4 Issue 29.