New Product Launch

2016 Quarter 4 Issue 29

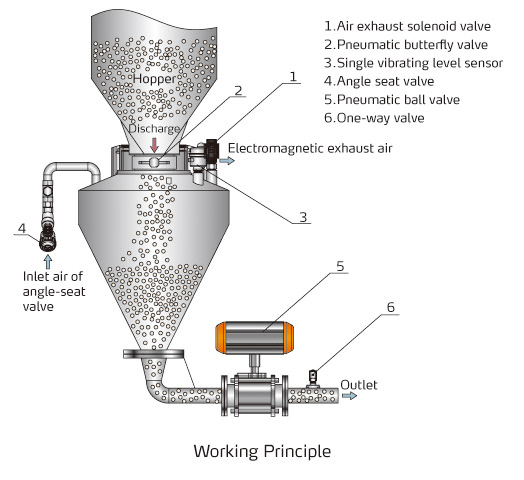

Positive Pressure Conveyor

•Main body adopts SUS304 stainless steel

•Adopt pneumatic conveying method,with high solid-gas ratio, it consumes less compressed air than conventional pneumatic conveying;

•Low speed conveying with less wear to the pipeline; the conventional steel pipe is available, low noise during operation

•Compact design requires less repair work

•Easy to achieve full-automation control,with reduced labor input

•Material discharge port is the 6’’pneumatic butterfly valve

•Flexible discharge of material, with covenient equipment layout

•Adopt electronic pressure switch in digital display, which enables to check the air pressure in real time; Alarm function activated if the pressure exceeds the set value.

•Adopt pneumatic angle seat valve, it works as switch, with pipe air-flow adjustment function.

Application

The positive pressure conveyor is the advanced device used for powder and granule conveying, with compact design, reliable operation, as well as low energy consumption for saving of input, it has been extensively used in plastic granule applications.

Air exhaust solenoid valve (1) opens, and the air exhaust is finished. Pneumatic butterfly valve (2) opens, the material will enter into the conveyor from storage hopper. When single vibrating level sensor (3) detects a certain material level, the pneumatic butterfly valve will close. Meanwhile, the angle seat valve (4) opens, and the air will enter into the conveyor. Once air pressure reaches the set point (0.4KG), the angle seat valve will close. Then pneumatic ball valve (5) opens, it will start conveying of material. By one-way valve (6), the air will segment the conveying processes for convenient conveying of material.

New Product Launch

If you want to read other articles, back to2016 Quarter 4 Issue 29.