New Product Launch

2017 Quarter 1 Issue 30

Classifier

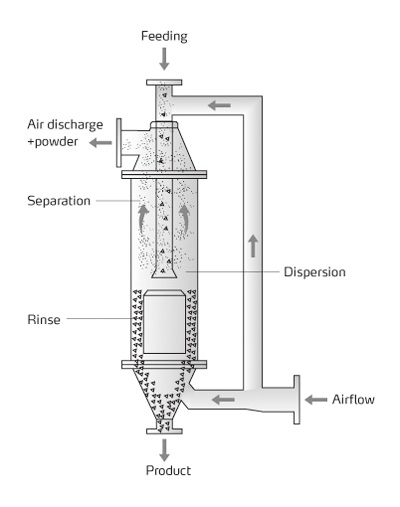

As to improve quality of various plastics (powder, scrap), it must get rid of impurities formed by production and air conveying processes. Shinchen Classifier is well-designed through many practical tests and experimental results.

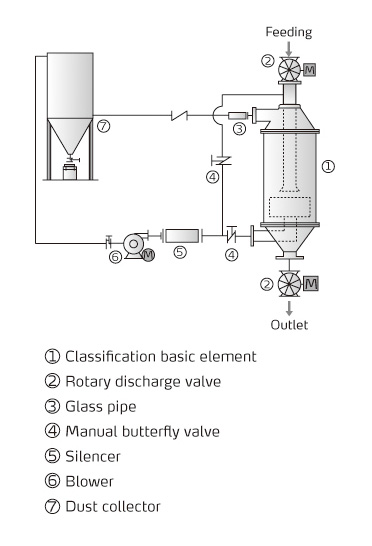

Classifying Principle

Feeding

Feeding

It usually connects with the outlet of rotary valve in pneumatic conveying, and to-be-classified materials are conveyed to dispersion part quantitatively and constantly.

Dispersion

After the to-be-classified materials getting into the feeding section, they will hit the cone part and be dispersed instantly. On the other hand, the secondary air passes through the diffusion hole after being blown by the outlet. The rectified airflow rises along with the cone part.

Rinse

Materials after dispersion is rinsed compulsively at the second rinse stage by the rising air flow. Especially for fine powder adhering on peelable particle, which is the most important part to improve classification property.

Separation

When rinsing, the separated particle and foreign matter are separated by differential floating velocity. After particles dropping, the foreign matter is excluded via the exhaust side.

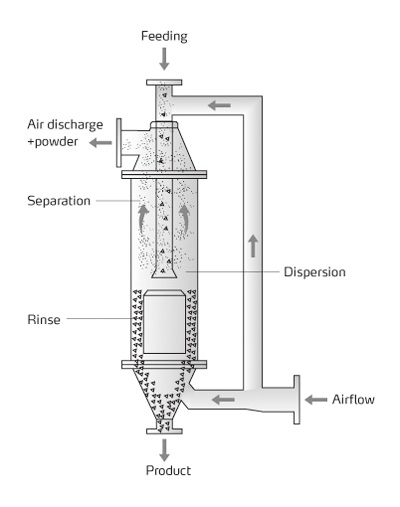

Application Range

The design principle is by differential floating velocity, so it could be applied in all classifications of powders and granules with different floating velocity. Simple structure of classifier and mass handling capacity is very suitable for classification of particles, foreign matters and plastic last conveying process.

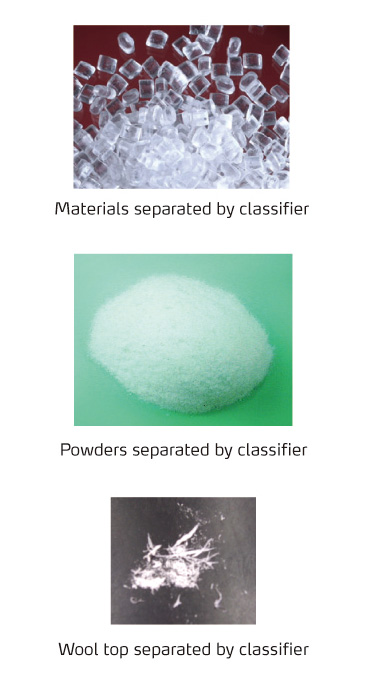

Below picture is the classification of classifier:

Classifying Principle

It usually connects with the outlet of rotary valve in pneumatic conveying, and to-be-classified materials are conveyed to dispersion part quantitatively and constantly.

Dispersion

After the to-be-classified materials getting into the feeding section, they will hit the cone part and be dispersed instantly. On the other hand, the secondary air passes through the diffusion hole after being blown by the outlet. The rectified airflow rises along with the cone part.

Rinse

Materials after dispersion is rinsed compulsively at the second rinse stage by the rising air flow. Especially for fine powder adhering on peelable particle, which is the most important part to improve classification property.

Separation

When rinsing, the separated particle and foreign matter are separated by differential floating velocity. After particles dropping, the foreign matter is excluded via the exhaust side.

Application Range

The design principle is by differential floating velocity, so it could be applied in all classifications of powders and granules with different floating velocity. Simple structure of classifier and mass handling capacity is very suitable for classification of particles, foreign matters and plastic last conveying process.

Below picture is the classification of classifier:

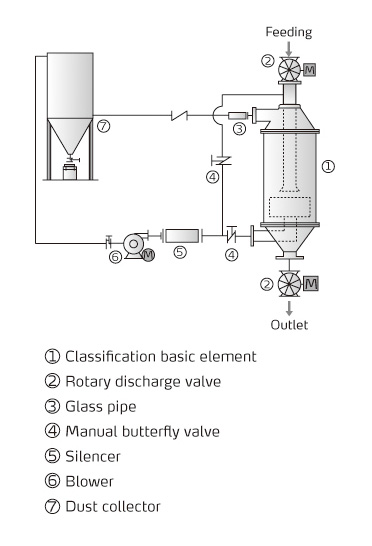

Flow chart of classification system