Special Reports

“One-to-Two” Compact Dryer

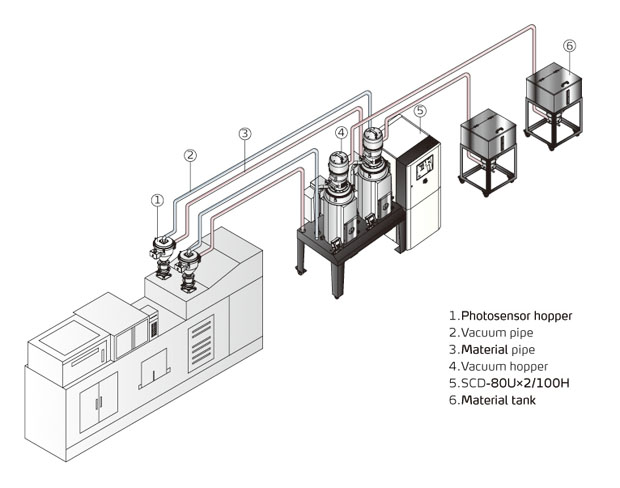

Today, two-component injection has become a massive manufacturing mode for continuous production. Taking advantage of latest technology, it gradually develops towards mechanization, automation and collectivization from manual operation at the beginning. The automated double-shot process is safe, high efficient and saves energy. In order to facilitate double shooter’s processing for two kinds of plastic granules, Shini launched the “One-to-Two” Compact Dryer SCD-80U*2/100H aiming of its safety, high efficient and energy saving performance.

SCD-80U*2/100H is assembled by one set of honeycomb rotor collocating with two drying hoppers that could replace two sets of separate drying and dehumidifying devices, which occupying less with even complete structure. Owning four-stage conveying function, it could dry two kinds of granules simultaneously. And its whole functions can be controlled through microcomputer, which could also control its single hopper’s temperature independently. Therefore, it fulfills the dehumidifying and drying for two kinds of granules on one machine, which feeds one set of double shooter correspondingly for high efficient drying and conveying.

Shini “One-to-Two” Compact Dryer SCD-80U*2/100H has less occupation that giving more space, and its integrated design carrying drying, dehumidifying and conveying functions are convenient for customer machine shift, installation and placing. Shini has been dedicated to make improvements and innovations on Dehumidifying Dryer since it was developed, and launched various safe, high efficient and low consumption modes for the market, offering multiple reassuring experiences for the customer.

Special Reports

- Application of SCAD Used in 3D Printing

- Dust Separators SDS-500

- “Large Flow” Water Heater STM-WFN

- Side Entry Robot

- Application of Valve Hot Runner

- Case Study of Pneumatic Conveying System

- My Shini Life

If you want to read other articles, back to2017 Quarter 2 Issue 31.