Special Reports

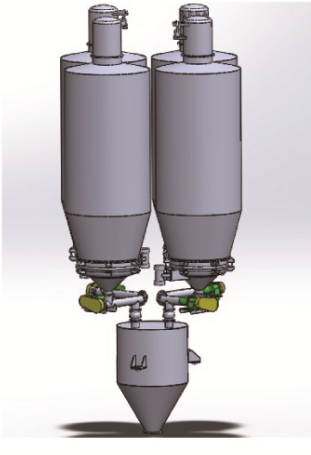

Automatic Batching System

This system is applicable to the measurement and batching of powder and granular material. It is a complete set of automatic equipments which conveys material through screws, belts and vibrating feeder, simultaneously achieving dynamic weighing and batching control.

Instructions

1.Electric control system adopts PLC, control program is designed according to customer’s requirement.

2.According to technical requirements, it controls the weight and flow of the material loaded on the batching weighting machine, calculating and distributing material accurately.

3.As an integral automatic control device that calculates and distributes material dynamically and constantly, this system can also provide accurate calculation data and control methods for various production control and management in different workshops.

4.The measuring precision meets the standard of electronic hopper scale tested by General Administration of Quality Supervision.

5.On the basis of technological process, different materials can be put into weigh hopper according to a predetermined formula and fixed proportion. When the indicated weight of each kind of material reaches its preset value, all materials will be discharged from the hopper and put into specific mixing equipment at one time or by turns, as a preparation of molding and bulk packaging.

6.This microcomputer system is equipped with automatic control function and weighing data management function. It can may record and print batching data.

Application

This system can be applied to industrial fields such as plastic, chemical, pharmaceutical, food, glass, ceramics, metallurgy, etc, being suitable for constant batching measurement and material distribution during production. It has several advantages: effectively enhancing distributing precision; improving product quality, greatly relieving workers burden, improving productivity and working environment. By utilizing this system, there will be only a little dust in batching workshops and the batching process can be unmanned. Enterprises can reduce production costs and labor force required by management, improving the technological level of their equipments and raising the science and technology content of their products.

Features

1.Microcomputer automatically controls whole production process.

2.The automatic operations of equipments are displayed on a LED monitor.

3.Operators can develop, modify and edit formulas.

4.Microcomputer can store multiple formulas.

5.Electronic hopper scale adopts double-speed charging, fast and accurately.

6.Flexible batching methods, convenient remote monitoring and simple onsite operation.

Special Reports

- Detailed Analysis of Hot Runner Technique - Optical Lens

- “Standard” Separate-vaccum Hopper Loader SAL-810G

If you want to read other articles, back to2017 Quarter 3 Issue 32.