Special Reports

Vertical Rotary Discharge Valve LRV40

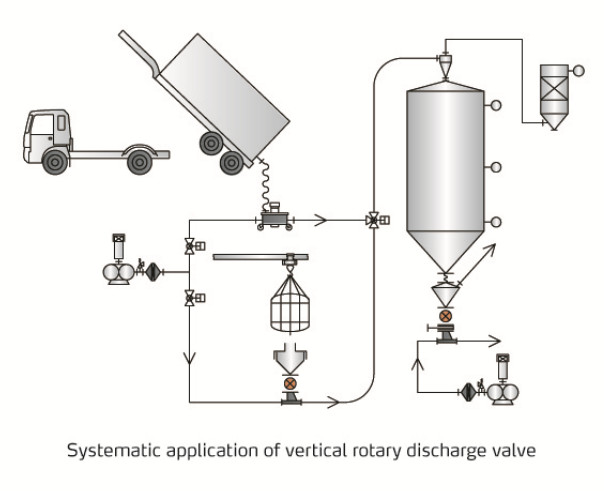

Vertical rotary discharge valve is a quantitative feeder in optimal design which can receive material (granule) from the container directly, and then convey the material to storage tank by air.

1.Characteristics of the design

The rotary shaft of vertical rotary discharge valve is in vertical direction. It receives material from upper cover and discharges material from middle part of the casing. The upper cover is connected with air conveying pipe which can convey the air from middle part of the casing. If the rotary shaft is in horizontal direction, an accelerating chamber will be necessary and there will be a long distance between two interfaces of the flange. In through-type circumstance, its lower part of the casing is connected with air conveying pipe and there is a long distance between two interfaces of the flange. For a vertical rotary discharge valve, the distance between material inlet and outlet on two interfaces is short. And both the material inlet and outlet are in V shape, which can prevent materials breaking caused by granules bite to some extent. Besides, vertical rotary discharge valve is movable, being equipped with standard casters.

2. Application advantages

1.It receives material from the container directly, and then conveys the material to storage tank by air. For being movable, it is able to receive materials everywhere. And if not being used, it can also be moved to a storage site, needing no fixed place;

2. The distance between storage tank as well as outlet and ground is short, which is an indispensible advantage of the equipment;

3.Vertical rotary discharge valve makes underground pit and drainage equipments unnecessary, and it can be put into operation everywhere. so operation costs can be saved.

Special Reports

- The Significance of COP to Cooling System

- The Usage of Heatless Air Dryer

- Central Material Conveying System

If you want to read other articles, back to2017 Quarter 4 Issue 33.