Special Reports

Details of Shini Granulating Cutter

There’s an old saying: “It’s necessary to sharpen the tools in advance if you want to make things go smooth”, which has been perfectly embodied in Shini Granulator, and the granulator cutter plays a decisive role for the high-efficient granulating process.

On the structure

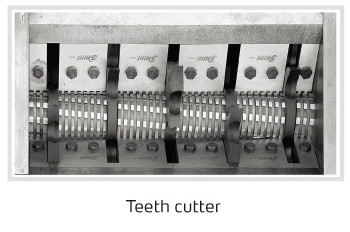

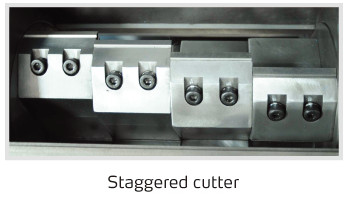

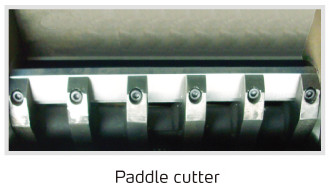

To differentiate the cutter from the structure, Shini Granulator mainly uses three kinds of cutters: teeth cutter, staggered cutter and paddle cutter.

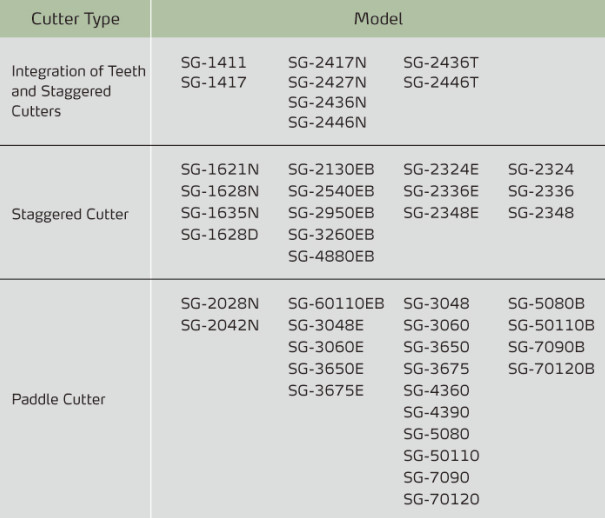

As the teeth cutter resembles pineapple, it is also called the pineapple cutter whose structure and processing technology are very complicated, which usually works with the staggered cutter. The staggered cutter can easily catch and destroy large sprues for the coarse grinding, and then the teeth cutter can give even fine grinding to the materials, finally obtaining the granule of required size. The coarse grinding and fine grinding can be processed together with high efficiency. The cutter structure features low rotating speed and low noise on its design, and the screenless design reduces the cost input of the easy broken parts. However, it also has obvious disadvantages: the granulating capacity is small, and initial cost of equipment input is also high as its complex cutter structure. This kind of cutters is mainly applicable to granulate the sprues, which is assembled on the granulator to work beside the IMM. The representative models are SG-24N and SG-14 series.

The staggered cutter usually adopts staggered and staircase layout, and the cutting angles between fixed blades are large. With a fewer cutters to granulate, the granulating resistance is rather small, which are more suitable for granulating the plates. Generally, the rotating blade is mounted on the blade rest that no need of adjustment and the fixed blade is mounted on the rack of cutting chamber that can achieve cutter gap compensation via adjusting screws. The staggered cutter is also called the disposable cutter, and is cheaper than the paddle cutter that can be replaced directly after long term use and no need of re-sharpening. The representative modes of the granulator with the cutter are SG-16N, SG-20NC, SG-23and SG-23E. In these models, SG-16N and SG-20NC are mainly used beside the IMM, and the SG-23 and SG-23E are mainly used for central granulating.

The paddle cutter adopts increased blade design and V-type cutting technology, and the increased blade structure looks like the domestic scissor that achieves material gradual granulating with less resistance. However, compared with the staggered cutter, its cutting angle between the rotating blade and fixed blade is small, ensuring bigger effective space in the cutting chamber, which is easier to catch the material, and is more suitable for granulating large housings. The V-type cutting technology is mainly used for models with large size cutting chamber. For these models, the cutting chamber is long. If each row of the rotating blade or fixed blade uses one blade, the blade’s processing cost will increase, and the convenience will decrease. Therefore, it usually divides the blade into two pieces in V type as to optimize the cutter size and push the material to the center during granulating, which reduces the abrasion of the structures on both sides of the cutting chamber, and improves the cutting efficiency of the middle parts in the chamber. The fixed blades of the paddle cutters are usually fixated on the rack of the cutting chamber, and the rotating blades are fixated on the blade rest that rotating with the shaft. The gap between the rotating blades can be adjusted by the presetting knife jig outside the machine to achieve quick and convenient clearance adjustment. The representative modes of the granulator with this cutter are SG-30/36/43/50/70 and corresponding E series that are mainly used for central granulating.

On the material

From the materials, the cutter of Shini Granulator mainly uses SKD11 and V-4E.

The cutter made of SKD 11 is mainly used for conventional material granulating, featuring high hardness and high wear resistance. SKD 11 is the Japanese steel code name that strictly focused on material selection. At first, it must have high strength and high hardness, but the cutter is easy to damage if it is too hard. Thus, the cutter is necessary to have certain toughness, keep good wear resistance and machining property, which requires reasonable and high processing precision. Taken the teeth cutter made by Shini as example, the process flow is as following: material feeding – hole drilling -molding-mold cutting- teeth milling- thermal treatment- sand blasting- inner grinding - external grinding - surface grinding- quality inspection, as well as many processes included. The shape of teeth cutter is very complicated so that the company uses four-axis machining center for the milling as to ensure the quality. Finally, for everyone, the high quality teeth cutter is visible, but our devotion on the manufacture is invisible.

V-4E is the Swedish steel code name. Compared with the SKD 11, it remains certain toughness while achieving higher hardness and wear resistance. Therefore, it is mainly used for granulating glass fiber contained materials. Normally, when the glass fiber content of the material is not larger than 30%, the granulator with this cutter can be applicable.

The cutter made of real materials with high-precision manufacture and elaborate design that used in Shini Granulator provides the customers with a “weapon” for easier granulating.

Special Reports

If you want to read other articles, back to2018 Quarter 2 Issue 35.