New Product Launch

“Budget” Series SG-24EB

Features

1.Excellent gear motor features reliable performance, long service life and high torque.

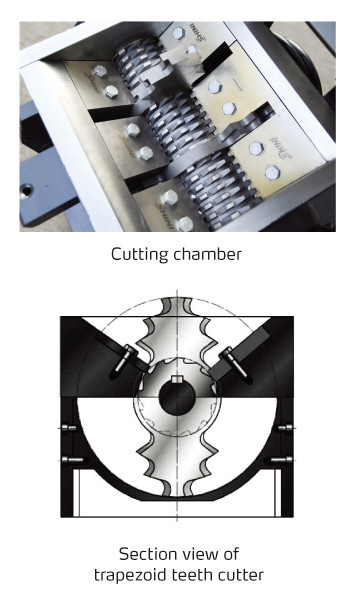

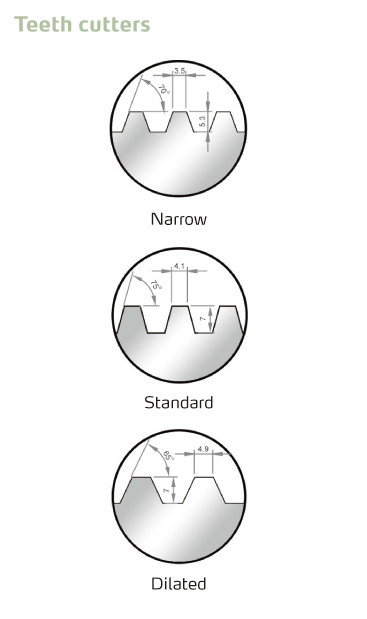

2.Integral design of teeth cutters and staggered blades makes coarse crushing and fine crushing simultaneously to mix with new materials.

3.Even granule with little dust.

4.Unique screw gearing transmission design makes it running stably with low noise level.

5.European type appearance, compact in size and easy for cleanig and maintenance.

6.Feeding hopper adopts visible window in welding way to make solid structure.

7.Easy motor installation and maintenance.

Application

SG-24EB series "standard" screenless granulators are suitable for instant recycling or granulating of hard and thick materials. With European-type appearance and compact size, they feature low rotating speed, low abrasion and super soundproof. Unique cutting blades design ensures well-proportioned granules and minimal amount of dusts. Easy for material cleaning and safe to operate. The unique transmission design cuts the cost greatly.

Options

Manual collection bin helps to collect and store regrind.

New Product Launch

If you want to read other articles, back to2018 Quarter 2 Issue 35.