Special Reports

Magnetic Central Chiller

Features

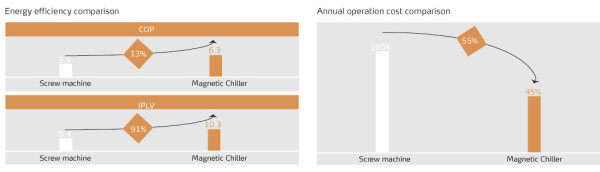

Energy saving

Adopt world famous magnetic oil-free inverter compressor, and single compressor start current of 2A without power network impact. The annual operation cost saves 55% compared with common centrifugal water chiller.

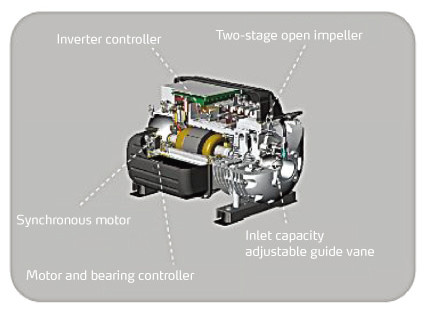

Oil-free operation

1.Magnetic bearing in energy consumption of 180W, which is far lower than traditional compressor mechanical loss (10000W).

2.The compressor rotor is in suspension during the operation, and there’re no frictional parts, so that the full system oil-free operation is realized.

3.Full system oil-free operation which avoids heat transfer loss due to lubricating oil formed oil film on heat exchanger surface for higher efficiency.

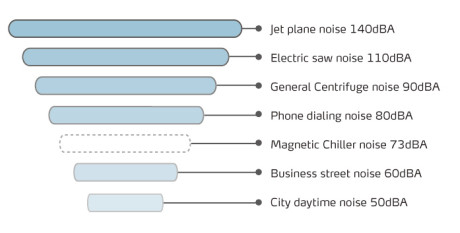

Environmental friendly without noise

1.Running noise level <73 dBA.

2.R134a environment-friendly refrigerant doesn’t deplete ozone layer which is safe, non-toxic and non hazardous.

3.The moving parts are completely suspended, frictionless and the structural vibration is close to 0 without the silencer.

Stable and durable

1.Stable operation performance with average service life>30 years.

2.Intelligent multi-level reliability control and power failure protection ensure safer compressor operation.

3.Permanent-magnet synchronous DC motor, direct-drive two-stage impeller and high-strength thermoplastic electronic shell ensure long-term operation.

4.Cooling range 7~25℃/44.6OF~77OF.

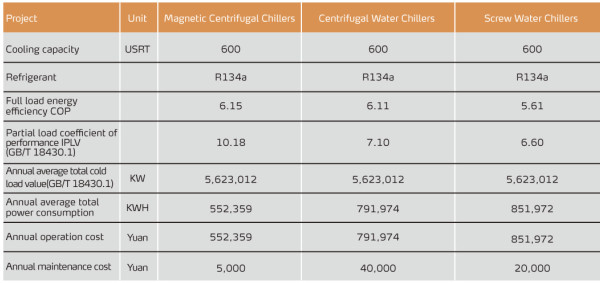

Operation cost comparison

Contrast model

Magnetic Centrifugal Water Chillers (high-efficient type) (600RT), Centrifugal Water Chillers (600RT), and Screw Water Chillers (600RT).

Operation state

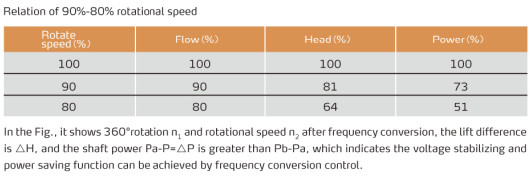

According to GB/T18430.1-2007 standard, 2.3% running time of the water chillers is under 100% full load condition, 41.5% running time of which is under 75% load condition, 46.1% running time of which is under 50% load condition, and 10.1% running time of which is under 50% load condition. The experimental results show that the parameters of the three types of chillers are as follows:

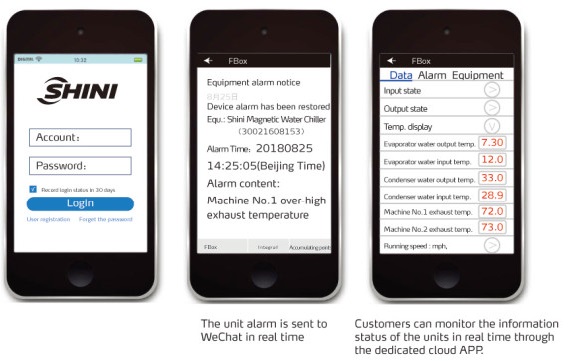

Cloud service system (option)

Cloud service system transfers large numbers of industrial equipment data or programs in different areas to remote cloud data center through the Internet (Ethernet, GPRS, 3G, etc.), which realizes remote data monitoring, equipment diagnosis, program maintenance and fault alarm lamp functions and provides users with a simple and reliable remote transmission plan for industrial Internet data.

Special Reports

If you want to read other articles, back to2018 Quarter 4 Issue 37.