Product Improvement

“Standard” Heater STM-405-E

Features

•P.I.D. multi-stage temperature control system can maintain stable mould temperature with an accuracy of ±

•Adopt high efficiency and thermostable pump.

•Multiple safety devices including power reverse phase protection, pump overload protection, overheat protection and low level protection that can automatically detect abnormal performance and indicate this by visible alarm.

Key Improvement

Simplify machine construction to reduce the size, add electronic high voltage protection.

Performance Price Ratio

The previous STM-405-E had a much bigger size and the internal structure was quite complicated. After improving, this machine features much higher cost performance, since its internal structure is simplified and the electronic high voltage protection function is added, which makes the whole machine more superior and more competitive in market.

Application

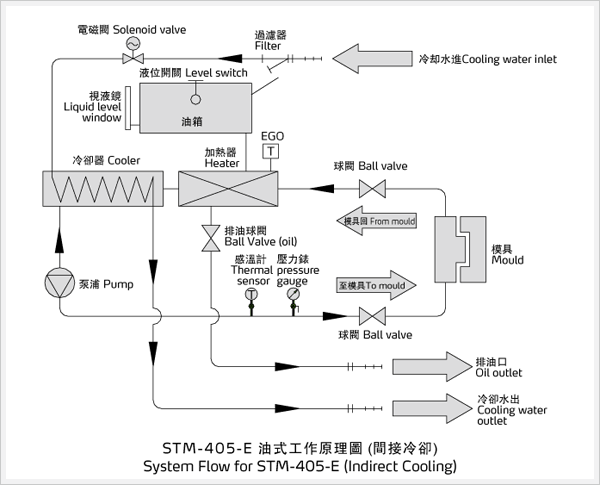

STM-E (WE) series are applicable for heating up moulds and maintaining temperature, and they also can be used in other similar applications. Firstly, these series adopt different cooling methods to cool down media, then media are conveyed to the moulds after pressurized by pump and heated up by electrical heated tube. The optimal design renders water be heated up to