New Product Launch

2014 Quarter 3 Issue 20

Shini Launches Modular Dryer SSMD-U

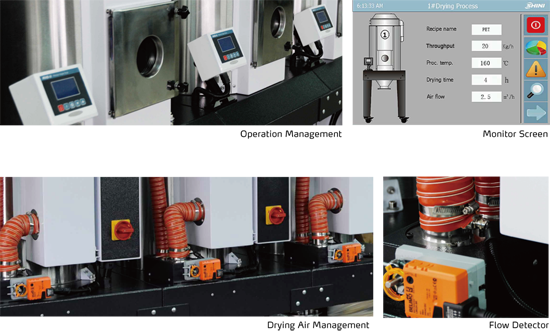

Shini smart modular dryer SSMD consists of a dehumidifier and several hopper dryers. The dehumidifier is equipped with a molecular sieve honeycomb rotor which has the dew-point air lower than -40℃ to ensure effective dehumidifying and drying for plastic material. The hopper dryers adopt design of modularization with capacity ranging from 20L to 600L. The drying tanks can be combined according to the actual needs of customers. Each hopper dryer in the modular assembly is respectively equipped with a heater, a temperature controller with communication function and auto regulator of air volume. Therefore, all hopper dryers can work independently without interference to each other.

SSMD adopts PLC & HMI control of SIEMENS whose humanized interface is easier to operate. The touch screen realizes to centrally control and monitor the working states and data of the dehumidifier and each hopper dryer. In addition, the temperature controller on each drying tank also can display temperature and be set independently. The outstanding feature of the control system is the application of the automatic air volume distribution control technology. The control system can calculate the required air volume for each hopper dryer according to the material type and throughput. With inverter, electric airflow valve and airflow sensor at each pipe system of the hopper dryer, it can precisely measure and adjust the airflow in each hopper dryer to the best operation conditions for each hopper dryer.

New Product Launch

- Energy-saving Hopper Dryer SHD-EH

- Application of Shini sLink Protocol Solution

- Bridge-breaking Hopper SBH

- Shini Blowing Machine in Molding Labeling SBI

- Mold Clamps

- Anti-vibration Pads

If you want to read other articles, back to2014 Quarter 3 Issue 20.