Special Reports

2014 Quarter 4 Issue 21

Shini Granulator Energy-saving Motor Update

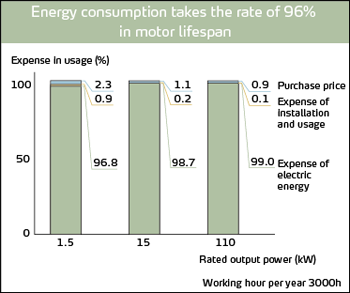

As energy and environment issue become more and more important, each country has formulated the energy-efficiency standard to the motor which is the main power equipment in industrial field–small & middle asynchronous motor. In general, compared with common motor, the qualified energy-efficiency motor can lower the consumption by 10% in average. For occasions as continuously in long-term operation and with high load-rate, the energy-saving effect is optimum.

Energy consumption of Shini granulator mainly come form the motor. As leader in the field, we constantly take our efforts to lower costs by pursuing high-efficiency motor. In this case, everyone can be benefited from the lower costs of longer motor lifespan.

Features of Shini granulator high-efficiency motor:

Features of Shini granulator high-efficiency motor:

•Comply with Secondary Level of standard GB18613-2006 as well as efficiency IEC60034-30 IE2.

•All the irons adopt high-quality cold silicon steel plates which possess excellent electrical performance, energy conservation and environmental protection.

•It’s applicable to inverter driving which with excellent energy-saving potential.

•Adopt self-cooling fan (IC411 specified in IEC60034-6) which can provide individual drive of cooling fan.

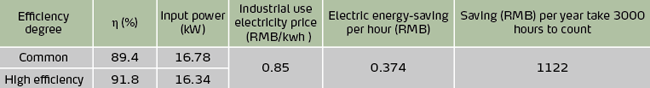

Motor energy-saving calculation:

Take 15kW 4 degree high-efficiency motor and common motor comparison as example

Above table just a simple calculation of motor power efficiency. If takes motor lifespan and inverter utilization

into consideration, the energy-saving rate will be higher.

Energy consumption of Shini granulator mainly come form the motor. As leader in the field, we constantly take our efforts to lower costs by pursuing high-efficiency motor. In this case, everyone can be benefited from the lower costs of longer motor lifespan.

•Comply with Secondary Level of standard GB18613-2006 as well as efficiency IEC60034-30 IE2.

•All the irons adopt high-quality cold silicon steel plates which possess excellent electrical performance, energy conservation and environmental protection.

•It’s applicable to inverter driving which with excellent energy-saving potential.

•Adopt self-cooling fan (IC411 specified in IEC60034-6) which can provide individual drive of cooling fan.

Motor energy-saving calculation:

Take 15kW 4 degree high-efficiency motor and common motor comparison as example

Above table just a simple calculation of motor power efficiency. If takes motor lifespan and inverter utilization

into consideration, the energy-saving rate will be higher.

Special Reports

- Shini Gravimetric Blender SGB Flakes Solution

- Gravimetric Blender SGB Data-collection Software

- Application of SLWF in Extrusion Molding Machine

- Oil Filter Applied in Plastics Drying and Dehumidifying

- Shini Launches Energy-saving Hopper Dryer SHD-EH

- Modular Drying and Dehumidifying

If you want to read other articles, back to2014 Quarter 4 Issue 21.