Special Reports

2014 Quarter 4 Issue 21

Application of SLWF in Extrusion Molding Machine

Extrusion Molding Method

There are two main methods in extrusion molding process: saturate molding and starve molding.

Types of The Feeder

SLWF Principle

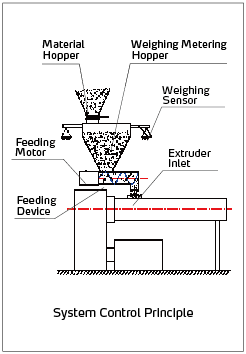

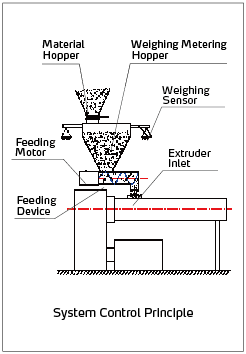

Install a motor-drive screw feeding device under the weighing hopper.Its function is to feeding material from hopper to extruder quantitatively. The feeding speed determines the throughput speed of extrusion molding machine. Measuring feeding speed equals throughput of the extrusion molding machine. Feeding device and loss-in-weight hopper form a whole unit, there’s no contact between feeding device outlet and extrusion molding machine inlet. Weight of the unit and its contained materials is centrally collected on the weighing sensor. So both fluctuation of weighing and materials in hopper can be accurately and timely figured out. The realization of measurement about material feeding speed is comparatively more convenient and accurate. Then use this signal as feedback of motor-drive rotating speed for feeding device which can accurately control feeding speed. In this method, productivity and products quality of total production lines can be controlled.

SLWF Construction

SLWF mainly consists of three parts including weighing hopper, feeding metering device, mixing device.

SLWF Control Principle

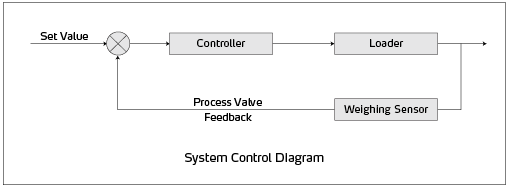

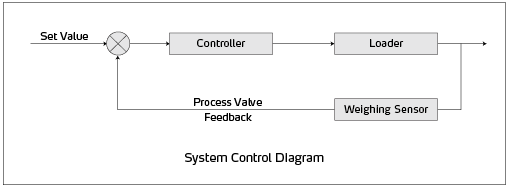

SLWF adopts loss-in-weight principle, by PLC and output capacity of inverter-control feeder screws enable it to satisfy proportional screw filling to reach the feeding purpose. As SLWF adopts weighing metering which precisely reflects the real-time feeding capacity. Through closed-loop controlling (as Pic.: system control principle), it could reach the purpose of precise feeding.

Shini SLWF

Main functions of Shini SLWF as below:

SLWF has wide range of application, it applicable for plastic granules, power, calcium carbonate, talcum powder, tree powder grain products and other materials. It can precisely control 4 ingredients feeding simultaneously. SLWF has stable discharging, in high accuracy and its feeding capacity with wide range of selection. Sing-drive method and extruder linkage-drive method are optional. High precise B&R PLC and weighing unit are optional which possess high accuracy and reliability, especially suitable for poor working condition. The controlling system can realize auto-filling handling, manual and automatic controlling can switch flexibly. SLWF equipped with standard network joint (ETHERNET) which has material level auto-filling function.

There are two main methods in extrusion molding process: saturate molding and starve molding.

Types of The Feeder

In feeding process of extrusion molding machine, volumetric feeder and loss-in-weight feeder are main equipments used in production. The volumetric feeder has simple construction and controlling which is low in costs. It mainly used in the condition that material has even bulk density and feeding accuracy is not very strict for final products quality. But the loss-in-weight feeder is used in the occasion that material has changing bulk density or feeding accuracy is very important for final products quality. For granules, feeder usually feeds the materials by single screw; for powder, it usually feeds the materials by double screws.

SLWF Principle

Install a motor-drive screw feeding device under the weighing hopper.Its function is to feeding material from hopper to extruder quantitatively. The feeding speed determines the throughput speed of extrusion molding machine. Measuring feeding speed equals throughput of the extrusion molding machine. Feeding device and loss-in-weight hopper form a whole unit, there’s no contact between feeding device outlet and extrusion molding machine inlet. Weight of the unit and its contained materials is centrally collected on the weighing sensor. So both fluctuation of weighing and materials in hopper can be accurately and timely figured out. The realization of measurement about material feeding speed is comparatively more convenient and accurate. Then use this signal as feedback of motor-drive rotating speed for feeding device which can accurately control feeding speed. In this method, productivity and products quality of total production lines can be controlled.

SLWF Construction

SLWF mainly consists of three parts including weighing hopper, feeding metering device, mixing device.

SLWF Control Principle

SLWF adopts loss-in-weight principle, by PLC and output capacity of inverter-control feeder screws enable it to satisfy proportional screw filling to reach the feeding purpose. As SLWF adopts weighing metering which precisely reflects the real-time feeding capacity. Through closed-loop controlling (as Pic.: system control principle), it could reach the purpose of precise feeding.

Shini SLWF

Main functions of Shini SLWF as below:

SLWF has wide range of application, it applicable for plastic granules, power, calcium carbonate, talcum powder, tree powder grain products and other materials. It can precisely control 4 ingredients feeding simultaneously. SLWF has stable discharging, in high accuracy and its feeding capacity with wide range of selection. Sing-drive method and extruder linkage-drive method are optional. High precise B&R PLC and weighing unit are optional which possess high accuracy and reliability, especially suitable for poor working condition. The controlling system can realize auto-filling handling, manual and automatic controlling can switch flexibly. SLWF equipped with standard network joint (ETHERNET) which has material level auto-filling function.

Special Reports

- Shini Gravimetric Blender SGB Flakes Solution

- Gravimetric Blender SGB Data-collection Software

- Shini Granulator Energy-saving Motor Update

- Oil Filter Applied in Plastics Drying and Dehumidifying

- Shini Launches Energy-saving Hopper Dryer SHD-EH

- Modular Drying and Dehumidifying

If you want to read other articles, back to2014 Quarter 4 Issue 21.