Special Reports

2015 Quarter 1 Issue 22

Teflon Coating Applied in SGB

Teflon, chemical named polytetrafluoroethylene, abbreviates as PTFE in English, is a fluorine atom substituted for all the hydrogen atoms in polyethylene which composed synthetic polymer materials, it also known as “plastic king”. Teflon features excellent anti-acid, anti-alkali and anti all kinds of organic solvent property. It is almost insoluble in all solvent. Meanwhile, it also is the high-temperature resistant material and the friction coefficient is very low. Besides its lubricant function, it also can act as ideal paint coated on inner layer of the non-stick pot and water pipe. Teflon coating generally named as “non-stick coating”. Almost all substances can’t adhere to Teflon coating. The special thin film also can display perfect non-stick characteristic.

Teflon coating is a kind of unique coating which possesses the comprehensive advantage that other coatings can’t compete with. Especially for its excellent non-stick property, Teflon coating applied in many fields all displayed good performance. Such as ovenware and all kinds of pastry moulds in food industry; drying cylinder, roller in textile machinery industry have perfect anti-sticking effect against pigment. It is easy for cleaning and don’t make cross contamination. The mould, laminating rollers, embossing roller, shoe mould, ball mould and other rubber moulds in rubber industry all obtained excellent effect in applications.

Considering the perfect comprehensive property of Teflon coating, Shini also introduced this coating in Gravimetric Blender SGB as well to cope with the special applications.

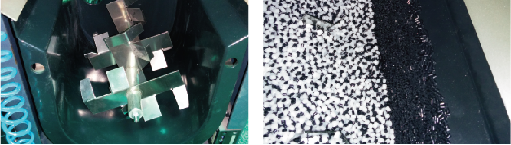

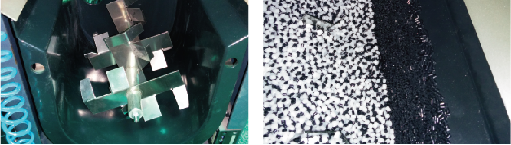

In diversity worlds of plastic industry that existed various kinds of raw materials. In order to deal with different kinds of material properties, Shini has put forward corresponding solutions as well. Hereby, we are going to share the experience with you. We have found a special master batch recently. For its special property, it was extremely easily to generate static in mixing or pneumatic conveying process as the friction. The master batches adhered together by static and attached to the mixing hopper, which are separated from the materials in layers. When material discharging valve of mixing hopper opens, the materials can not free-flow completely and smoothly which will lead to mixing proportion deviation and finally affect products quality. Under the condition that without good results from the experiments, our aim had transferred to the Teflon coating. Hope its excellent non-stick property enables to prevent the master batches from adhering to the mixing hopper completely. Without doubts, we painted the mixing hopper inside with Teflon coating according to the experiments. The master batches attached on the inside hopper are able to fall down into below storage tank without blockage. Residuals left in mixing hopper would affect plastic products quality no more. Finally, the issues had been solved.

With the experience and aim better to solve the similar situations, we determine to define the mixing hopper painted with Teflon coating as the option of Gravimetric Blender SGB. In this way, Shini is able to offer all customers better precise and considerable service.

Teflon coating is a kind of unique coating which possesses the comprehensive advantage that other coatings can’t compete with. Especially for its excellent non-stick property, Teflon coating applied in many fields all displayed good performance. Such as ovenware and all kinds of pastry moulds in food industry; drying cylinder, roller in textile machinery industry have perfect anti-sticking effect against pigment. It is easy for cleaning and don’t make cross contamination. The mould, laminating rollers, embossing roller, shoe mould, ball mould and other rubber moulds in rubber industry all obtained excellent effect in applications.

Considering the perfect comprehensive property of Teflon coating, Shini also introduced this coating in Gravimetric Blender SGB as well to cope with the special applications.

In diversity worlds of plastic industry that existed various kinds of raw materials. In order to deal with different kinds of material properties, Shini has put forward corresponding solutions as well. Hereby, we are going to share the experience with you. We have found a special master batch recently. For its special property, it was extremely easily to generate static in mixing or pneumatic conveying process as the friction. The master batches adhered together by static and attached to the mixing hopper, which are separated from the materials in layers. When material discharging valve of mixing hopper opens, the materials can not free-flow completely and smoothly which will lead to mixing proportion deviation and finally affect products quality. Under the condition that without good results from the experiments, our aim had transferred to the Teflon coating. Hope its excellent non-stick property enables to prevent the master batches from adhering to the mixing hopper completely. Without doubts, we painted the mixing hopper inside with Teflon coating according to the experiments. The master batches attached on the inside hopper are able to fall down into below storage tank without blockage. Residuals left in mixing hopper would affect plastic products quality no more. Finally, the issues had been solved.

With the experience and aim better to solve the similar situations, we determine to define the mixing hopper painted with Teflon coating as the option of Gravimetric Blender SGB. In this way, Shini is able to offer all customers better precise and considerable service.

Special Reports

- The Preview of Shini Auxiliary Equipment on Chinaplas2015 Show

- Mold Sweat Dehumidifier Upgrade

- sLink Protocol Solution

- Shini Robot Introduction

- Hot runner introduction

- Shini Japan

If you want to read other articles, back to2015 Quarter 1 Issue 22.