New Product Launch

2015 Quarter 1 Issue 22

Central Granulator SG-50E

SG-50E series granulators are applicable to granulate various kinds of plastic materials from injection molding, blow molding or extrusion molding. This series features compact design, easy operation and quick blade replacement. It is equipped with high efficient motor, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offers a better cutting effect and a lower noise level.

The design highlights

New cutting technology

Compared with general motor, high-efficiency motor with consumption lower by 10% and longer in lifespan.

Electronic handspike

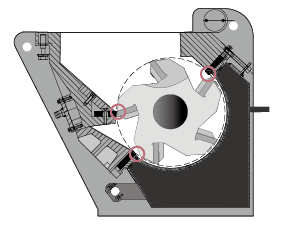

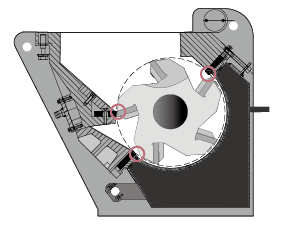

New cutting technology

Rotating cutters adopt newly developed V-type cutting technology which can send the feeding material into the center of rotating cutters so to prevent the material from adhering onto the inner side of the cutting chamber while enhancing its wearability.

Cutters adjustment technology

Cutters adjustment technology

Equipped with presetting knife jig, the pitch between rotating blades and fixed blades can be pre-adjusted. It made blades adjustment much easier.

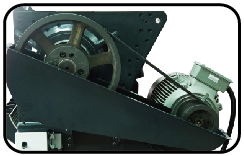

Heavy duty transmission design

Heavy duty transmission design

V-type transmission belts help maintain a balanced operation mode, close contact, and also easy to disassemble and repair.

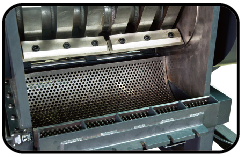

High quality crushing chamber

Cutting chamber made of high rigidity material, after processing by CNC machine, has the features like high intensity, super wearability, no contamination, long service life and easy for maintenance and repairing.

High efficiency motor

High efficiency motor

Compared with general motor, high-efficiency motor with consumption lower by 10% and longer in lifespan.

Electronic handspike

Feeding box which is opened by electrical handspike with self-lock function ensures safe operation.

Cutting tool structure

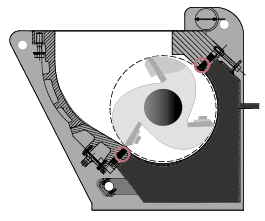

High cutting point

High cutting point

High cutting point fixed blades model has small inlet space and initially high cutting point. Thus its cutting force is not so strong, which enhances the reliability of cutting solid material. This design is suitable for granulating solid material with thick wall and sheet.

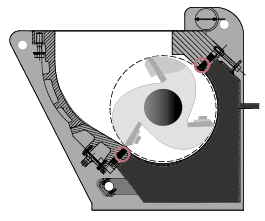

Low cutting point

Low cutting point

Low cutting fixed point blades with big inlet space. Material can be easily grabbed and cut thus making this rotor/housing combination ideal for the granulation of large and hollow objects and frame material.

New Product Launch

If you want to read other articles, back to2015 Quarter 1 Issue 22.