Experience Sharing

2016 Quarter 2 Issue 27

Shini sLink Technology Used in IMM Control System

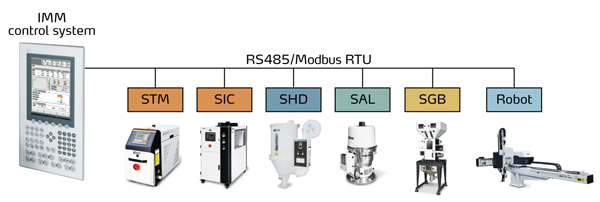

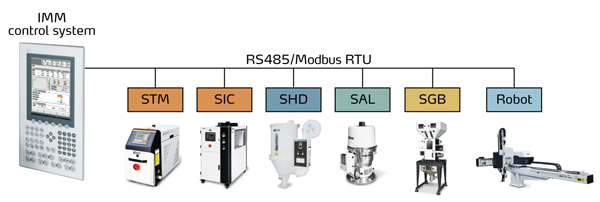

B&R is a global leader in the field of automation technology headquartered in Austria, and was established in 1979. In plastics industry, B & R offers system solution applications for domestic and foreign manufacturers, which wins wide reputations in the industry. To meet customer demand for the high-efficient and intelligent injection molding system, B & R upgraded its particular IMM control system Smartmold88.The new control system integrated sLink technology can achieve the combination between IMM and Shini auxiliary equipment.

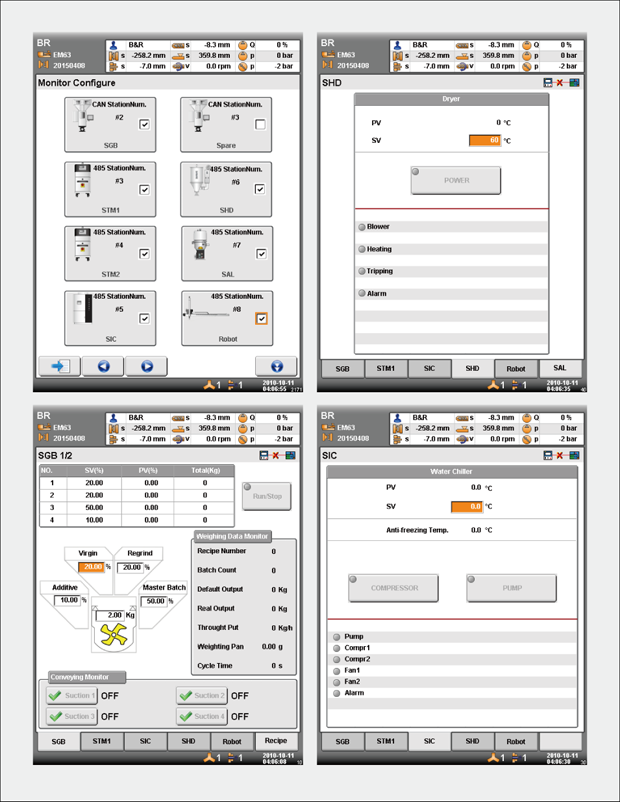

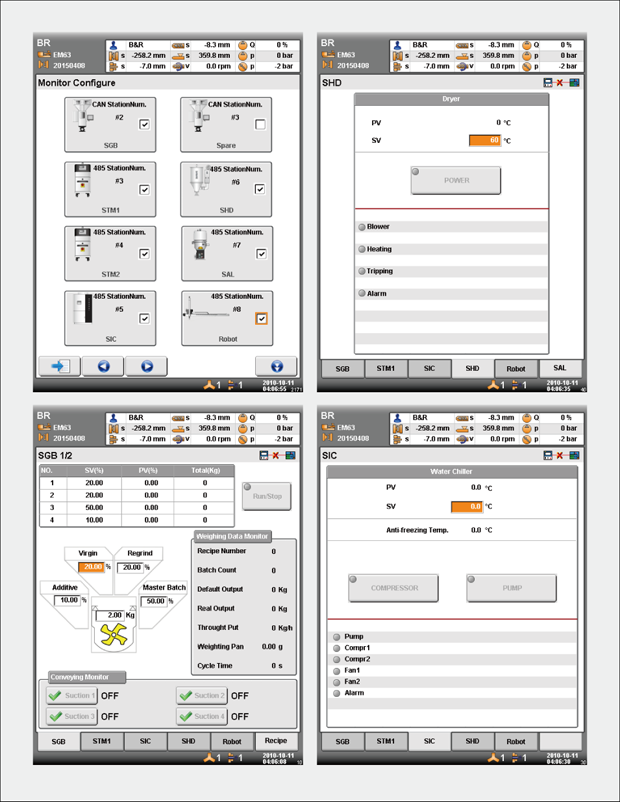

B & R Smartmold88 IMM control system connects Shini equipment through RS-485 communication port, to process central monitoring of the dryer, drying loader, mould temperature controller, water chiller, mixing blender and robot in IMM controller. According to data collection and analysis, it can create production resume of each machine which is convenient for technological parameter access and quality analysis afterwards.

B & R Smartmold88 IMM control system connects Shini equipment through RS-485 communication port, to process central monitoring of the dryer, drying loader, mould temperature controller, water chiller, mixing blender and robot in IMM controller. According to data collection and analysis, it can create production resume of each machine which is convenient for technological parameter access and quality analysis afterwards.

The control system bonds with the sLink technology, which is easy to achieve the integration between IMM and various auxiliary equipments. Shini is searching for collaboration with the IMM and control system manufacturers actively, devoting itself to enhance the intelligence level of the injection system, and improve the production efficiency.

The control system bonds with the sLink technology, which is easy to achieve the integration between IMM and various auxiliary equipments. Shini is searching for collaboration with the IMM and control system manufacturers actively, devoting itself to enhance the intelligence level of the injection system, and improve the production efficiency.

Experience Sharing

- Application of Shini Robots Combined with Central Conveying System

- Successful Case of Servo Driven Swing-arm Robot in Electronic Industry

- Application Case of Central Conveying System

If you want to read other articles, back to2016 Quarter 2 Issue 27.