Special Reports

2016 Quarter 2 Issue 27

Energy Saving Technology Applied in Water Chiller

Energy saving technology takes advanced methods to achieve the purpose of energy saving. In the same condition, if industrial Water Chiller consumes low power, it will cut down power expenses under the premise when it meets production requirement. Especially for the enterprise uses industrial Water Chiller for 24-hours production, this technology will largely reduce the costs when using the equipment. Client also prefers high-efficient Water Chiller with reliable operation and low failure rate for long service life.

The Water Chillers system consists of three interconnected systems, which include the refrigerant circulation, water circulation and electrical unit auto-control system. Shini Water Chiller improves these three systems to raise energy-saving efficiency.

Refrigeration Circulation

The liquid refrigerant in evaporator absorbs water heat and starts to evaporate, eventually forms a certain degree of temperature difference between the refrigerant and water. After liquid refrigerant is completely evaporated to gaseous state, it will be absorbed by the compressor (higher pressure and temperature). The gaseous refrigerant releases its heat through the condenser (air-cooled /water-cooled), and condenses to liquid state. Through expansion valve (or capillary throttle), it will be turned to low- temperature low-pressure refrigerant and enter into the evaporator, which completing the refrigerant circulation. In the circulation, Shini is aiming to improve the energy efficiency; the COP value would be over the 1 grade of the China standard, which not only lowers power input but also outputs higher cooling capacity.

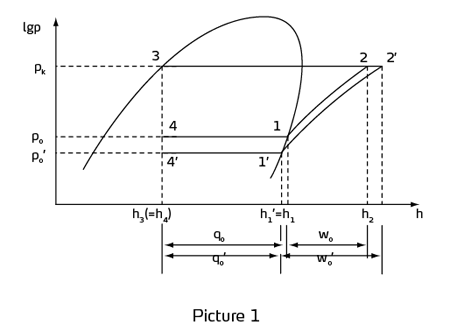

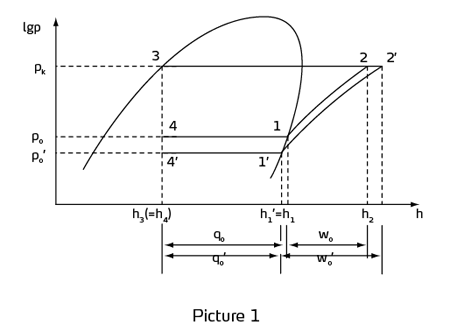

Adopting reliable and high-efficient compressor, the COP value would reach a higher level. It is the key point to save energy by reducing electricity consumption. The evaporation and condensation temperature are key elements of the refrigerant circulation system. Under the premise when it meets safety regulation and production requirement, improve evaporation temperature or lessen condensing temperature can promote the COP level (as picture 1).

1.The evaporation pressure rises as evaporation temperature climbs, compressor exhausting temperature drops from t’2 to t2.

2.The cooling capacity per unit mass rises from q’0 to q0, suction specific volume reduces, and refrigerant cooling capacity per unit is enhancing.

3.As suction specific volume is reduced, results the mass flow rate of refrigerant increasing, therefore the cooling capacity Q0 rises obviously.

4.The theoretical specific work (consumption power of compressor conveying 1kg refrigerant vapor according to isentropic compression) drops to wo from w’0.

5.As refrigeration coefficient is the ratio between cooling capacity per unit mass and theoretical specific work, obviously, it increases as evaporation temperature rises.

When cooling capacity per unit mass rises, power consumption will be cut down, as refrigeration coefficient increases, the performance of refrigeration circulation and the Water Chiller will be both improved. Condensation temperature works as the same theory, generally speaking, the evaporation temperature has much powerful influence than condensation temperature to affect the Water Chiller performance. Therefore, Shini pays more attention to the raise of evaporation temperature for the higher COP level. To Water Chiller, heat-dissipation is very important. The refrigerant system performs better with good heat-dissipation. To Water-cooled Water Chiller, cooling tower’s configuration is particularly important. It is necessary to choose a matching cooling tower to ensure a better sufficient dissipation performance of the condenser. While for Air-cooled Water Chiller, the cooling fan should be adequate to dissipate the heat.

Water Circulation

Water pump is responsible to draw water to specific cooling equipment from the tank. Chilling water takes the heat away, and with increasing temperature, it returns to the chilling water tank. To save energy in water circulation, customer is required to process regular cleaning to prevent or reduce pipe incrustation, as to improve the heat- exchange efficiency of both condenser and evaporator. Water quality also has certain requirements. Without proper treatment, calcium carbonate and magnesium carbonate formed by heat-up calcium bicarbonate and magnesium bicarbonate will be deposited on the pipeline, resulting poor heat conduction and heat exchange rate of both condenser and evaporator. It largely increases the electricity consumption. Therefore, employing a filter will improve the heat exchange rate. In low-temperature, low high-pressure winter, the compressor is often damaged by overheat operation or lubrication failures. The new generation of Shini Water-cooled Water Chiller will employ water sluice valve, according cooling water temperature to adjust water flow-rate automatically. Stabilize high pressure value of the refrigerating system to the optimal operation. Moreover, equipped with reverse-cleaning filer, the compact plate-evaporator is capable to perform excellent heat exchange.

Electrical Unit Auto-control

It includes power and auto control. The power connects through contactor, compressor, cooling fan and water pump.

The auto control integrates temperature controller, pressure protector, delayer, relay, and overload protector units, according water temperature to process auto start and stop as well as protection functions, which offering a safe and low cost operation for the customer. With appropriate load adjustment and safe operation, the units keep 70%~80% load rate requiring lower consumption per cooling capacity than the full load operation. This method needs consideration based on water pump and cooling tower working conditions.

The Water Chillers system consists of three interconnected systems, which include the refrigerant circulation, water circulation and electrical unit auto-control system. Shini Water Chiller improves these three systems to raise energy-saving efficiency.

Refrigeration Circulation

The liquid refrigerant in evaporator absorbs water heat and starts to evaporate, eventually forms a certain degree of temperature difference between the refrigerant and water. After liquid refrigerant is completely evaporated to gaseous state, it will be absorbed by the compressor (higher pressure and temperature). The gaseous refrigerant releases its heat through the condenser (air-cooled /water-cooled), and condenses to liquid state. Through expansion valve (or capillary throttle), it will be turned to low- temperature low-pressure refrigerant and enter into the evaporator, which completing the refrigerant circulation. In the circulation, Shini is aiming to improve the energy efficiency; the COP value would be over the 1 grade of the China standard, which not only lowers power input but also outputs higher cooling capacity.

Adopting reliable and high-efficient compressor, the COP value would reach a higher level. It is the key point to save energy by reducing electricity consumption. The evaporation and condensation temperature are key elements of the refrigerant circulation system. Under the premise when it meets safety regulation and production requirement, improve evaporation temperature or lessen condensing temperature can promote the COP level (as picture 1).

1.The evaporation pressure rises as evaporation temperature climbs, compressor exhausting temperature drops from t’2 to t2.

2.The cooling capacity per unit mass rises from q’0 to q0, suction specific volume reduces, and refrigerant cooling capacity per unit is enhancing.

3.As suction specific volume is reduced, results the mass flow rate of refrigerant increasing, therefore the cooling capacity Q0 rises obviously.

4.The theoretical specific work (consumption power of compressor conveying 1kg refrigerant vapor according to isentropic compression) drops to wo from w’0.

5.As refrigeration coefficient is the ratio between cooling capacity per unit mass and theoretical specific work, obviously, it increases as evaporation temperature rises.

When cooling capacity per unit mass rises, power consumption will be cut down, as refrigeration coefficient increases, the performance of refrigeration circulation and the Water Chiller will be both improved. Condensation temperature works as the same theory, generally speaking, the evaporation temperature has much powerful influence than condensation temperature to affect the Water Chiller performance. Therefore, Shini pays more attention to the raise of evaporation temperature for the higher COP level. To Water Chiller, heat-dissipation is very important. The refrigerant system performs better with good heat-dissipation. To Water-cooled Water Chiller, cooling tower’s configuration is particularly important. It is necessary to choose a matching cooling tower to ensure a better sufficient dissipation performance of the condenser. While for Air-cooled Water Chiller, the cooling fan should be adequate to dissipate the heat.

Water Circulation

Water pump is responsible to draw water to specific cooling equipment from the tank. Chilling water takes the heat away, and with increasing temperature, it returns to the chilling water tank. To save energy in water circulation, customer is required to process regular cleaning to prevent or reduce pipe incrustation, as to improve the heat- exchange efficiency of both condenser and evaporator. Water quality also has certain requirements. Without proper treatment, calcium carbonate and magnesium carbonate formed by heat-up calcium bicarbonate and magnesium bicarbonate will be deposited on the pipeline, resulting poor heat conduction and heat exchange rate of both condenser and evaporator. It largely increases the electricity consumption. Therefore, employing a filter will improve the heat exchange rate. In low-temperature, low high-pressure winter, the compressor is often damaged by overheat operation or lubrication failures. The new generation of Shini Water-cooled Water Chiller will employ water sluice valve, according cooling water temperature to adjust water flow-rate automatically. Stabilize high pressure value of the refrigerating system to the optimal operation. Moreover, equipped with reverse-cleaning filer, the compact plate-evaporator is capable to perform excellent heat exchange.

Electrical Unit Auto-control

It includes power and auto control. The power connects through contactor, compressor, cooling fan and water pump.

The auto control integrates temperature controller, pressure protector, delayer, relay, and overload protector units, according water temperature to process auto start and stop as well as protection functions, which offering a safe and low cost operation for the customer. With appropriate load adjustment and safe operation, the units keep 70%~80% load rate requiring lower consumption per cooling capacity than the full load operation. This method needs consideration based on water pump and cooling tower working conditions.

Special Reports

- Make Your Imagination Thousands of Surprises

- Review 2015 and Look Forward to 2016

- Model Selection and Notices of Cooling Tower

- Rotary Valve

- "The Classroom" Debuted A Huge Success

If you want to read other articles, back to2016 Quarter 2 Issue 27.