Special Reports

2016 Quarter 3 Issue 28

MES Intelligent Manufacturing Integrated System

Under globalization background, enterprises are facing unpredictable competitiveness with increasing of diversity customer demands, shorter production cycle, and even decentralized production units. In this period, the customer plays dominant factor to influence market than ever before. To maintain the competitiveness, they must to meet higher quality demand of the customer. Moreover, the enterprise should be capable to produce lower cost product more innovatively within short delivery time. Under this background, the enterprises raise even high request for IT system. For manufacture enterprise, as continuous changing demands, the manufacturer has to fulfill the information exchange between the factory and supply network in time, and react more quickly and effectively. Especially for the situation that whole industry is taking manual work to integrate ERP (enterprise resource plan) system and program for workshop manufacture.

According to AMR Research and Managing Automation in Oct. 2005, the investigation of “From Production Operation to Supply Network Operation: Challenge of Small and Medium Manufacturing Enterprises” reveals that only less than 1% of enterprises are using the automated integration of ERP and real-time production system. In this situation, it is hard to achieve information exchange timely, but it is essential to improve the entire enterprise performance. Facing the challenge, the enterprise not only needs to collect suitable factory data, but analyzes it, to support real-time decisions. Afterwards, it has to submit data with direct presentation to workshop or appointed address, which offers support for high-efficient decision.

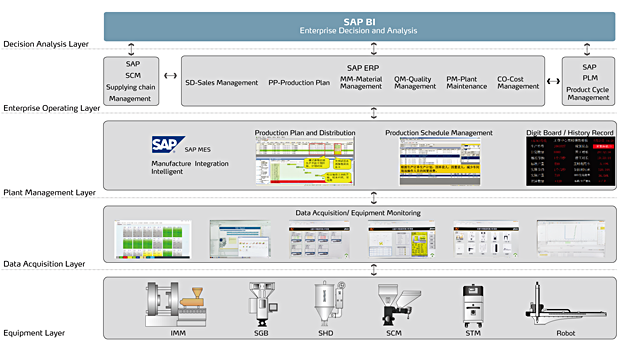

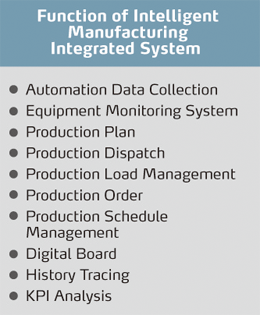

MES Intelligent Manufacture Integrated System via SAP MII platform to establish manufacturing executive system, based on batch process control, it provides data collection, control, analysis and history access in real time, from material on time, process processing, and product in warehouse to whole production process. It is the ensuring system of planning, logistics, production, and quality departments within enterprise to get the first-hand information which effectively ensuring real-time production, transparent management and history data tracing, which directly improve the executing of manufacturing orders. It connects with ERP and workshop system, accurately displays the management state in real-time, which helps manufacturer to achieve excellent manufacturing.

Special Reports

- sLink --Protocol Solution

- Exhibition News of Chinaplas2016

- Introduction of Gram-meter Control System

- Shini Central Granulator—Regular & Budget Series

If you want to read other articles, back to2016 Quarter 3 Issue 28.