Experience Sharing

Case of "Large Flow"Water Heater STM-910WF Application

With the rapid development of economy, people develop new understanding of the life quality. The clothes, food, shelter, and travel are the four essential factors in people’s lives. However, the travel is the most common factor and one of the most important aspects of living factor. From original carriage to current cars, high-speed trains and aircrafts, all are the main means of transport for people travelling needs, and the cars are almost in the possession of every family. With growing demands for the cars, the accessory parts of the vehicle have also increased accordingly.

A company in Chongqing is the large enterprise specialized in producing automotive light accessories, which employs multiple sets of large IMMs to use in auto light production. Based on the production process, the mold temperature controller is required to stabilize the mold temperature for quality improvement. After deep discussion with the customer, we preliminarily recommended the STM-910WF “Large Flow” Water Heater to the customer, but we have improved some parts of the machine in accordance with the actual demands and upgraded the model to STM-910WFN, satisfying the customers’ needs for the personalized product.

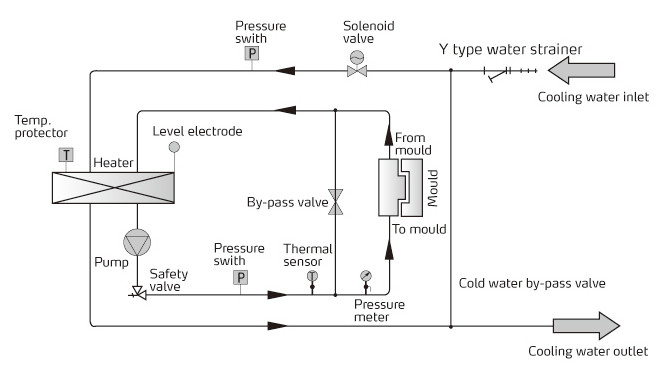

Working principle

The water in the heating tank is conveyed to the mold through high-pressure centrifugal pump after heating, which heats up the mold and then returns to the heating tank to finish the cycle. If the water temperature in the whole circulation is too high, it will be sent to the control system via temperature sensor, and then the system will start the solenoid valve. After cold water enters the system to cool down the water, the solenoid valve will be close till the temperature is cooled to system set temperature, which achieves the purpose of constant water temperature in the circulation. If the temperature exceeds upper limit of temperature protector (snap action thermostat), the system will alarm and stop. In the process, if the pressure continues to rise, the safety valve will open to release the pressure for the safety. If there’s a loss in water system during the operation, the water level in the system will reduce. When the level sensor detects the level has reduced, the system will open the solenoid valve to replenish the water; and it will close the valve if the water level has been detected as to prevent dry burning in the heating tank.

Main features

The P.I.D temperature control system can maintain stable mold temperature, and the control accuracy also can reach ±0.50C; High-performance vertical multistage centrifugal water pump can meet the demand of large flow, and whole water circulation pipe is made of stainless steel that prevents circulating water pollution, and it can reach the max. temperature of 1200C. Moreover, the RS485 communication interface it equipped to achieve interconnection with most machines for convenient centralized monitoring.

Major improvement points

It adopts direct water level control, and high-precision level sensor on the surface of heating tank. If the water level drops, the level sensor can immediately detect the system’s water shortage, and the water replenishing device will start to fill the water, which prevents water pump running without water; The pressure-release water is mounted at the high pressure side of the water loop to detect the pressure automatically. Once it exceeds the designed pressure, the system will automatically discharge the water and release the pressure to ensure safe machine operation that avoids the accident. Mechanical EGO is upgraded to the high-precision electronic temperature protector, which can quickly and accurately determine whether the system is overheated.

This Water Heater has been used in the factory for a long time, and its stable and reliable performance can fully satisfy the customer’s demands.

Experience Sharing

- Vehicle Lamps of Central Conveying System

- Case Sharing of Central Conveying System

- Application of Mold Monitoring System in Acoustic Part Injection Molding

If you want to read other articles, back to2018 Quarter 2 Issue 35.