Experience Sharing

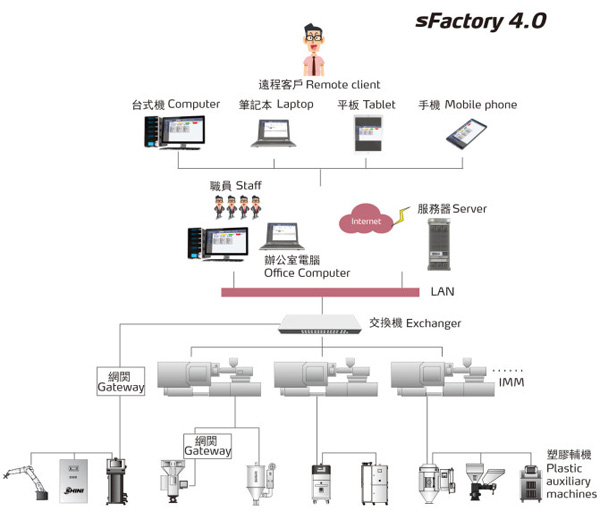

Application of Industrial 4.0 Smart Plant

The whole system is composed by the central feeding system and central drying system that mainly processes three kinds of materials: PS, PC and ABS. The central feeding system equips the high pressure blower and central filter, and the conveying pipe that mainly made of stainless steel is used to prolong the service life of the pipe bend, which has glass tube or special material pipe as alternatives.

The central cooling water system mainly consists of the host CFC-free Refrigerant Central Air-cooled Water Chiller and constant pressure water-supply pumping stations with the steel plastic pipe, which takes away the heat produced by field equipment for constant water temperature.

Overview

Central Material Processing System

Central conveying : equipped with the high-pressure blower and central filter arranged with stainless steel pipes; glass tubes or special material pipes can be selected for pipe bends.

Central drying: Smart modular dehumidifying dryers are composed by one set of honeycomb dehumidifier SD-H-SM and three sets of modular hopper dryers MHD-U that enable accurate auto-control of the drying airflow as material dosage through on-line communication. It can avoid over or insufficient material drying, and the drying temperature of each hopper also should also be controlled separately as demands.

Real-time monitoring and displaying various parameters of the 3-phase power , which can process data remote transmission or upload to upper units for centralized monitoring through the Modbus RTU communication protocol.

Real-time monitoring and displaying the temperature of the inlet and outlet flow rate to calculate the instantaneous power and accumulative energy, which can process data remote transmission or upload to upper units for centralized monitoring via the Modbus RTU communication protocol.

Water and Electric System

The central cooling water system mainly consists of the host CFC-free Refrigerant Central Air-cooled Water Chiller and pump group with the steel plastic pipe for constant system pressure. It is also equipped with control devices for cooling power consumption, cooling water flow and inlet and outlet temperature monitoring for easy data acquisition. The electrical system employs smart meter to detect real-time energy consumption and power state of various intelligent productions. The compressed air system mainly features fast pipe configuration.

Automation System

Injection Molding Unit: Disposable Plastic Cup. With compatible sLink technology, it achieves smooth data transmission between the equipments. The whole system manipulates the whole process of injection molding, arranging, stacking, delivering, packaging and the logistics in the production, which is applicable to hot runner molds, thin-wall and multi-cavities, short-cycle tableware and kitchenware occasions.

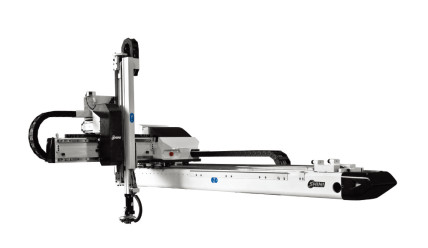

Shini high speed three axes servo driven robot (telescopic arm) , all axes are driven by servo motors. Capable of arranging, stacking, quality checking and in mold placement. Suitable for hot runner system and short cycle time injection molding machine with clamping force ranging from 200T to 300T.

AGV also named as automatic driverless cart, it is a mobile robotic vehicle equipped with safety device that follows the required route to move products or deliver loads, which is used in automobile, electronics, home appliances and other industries.

Flexible multiple degree of freedom movement provides optimized moving path. Widely used in palletizing, handling, processing, injection molding and other occasions, advantages are more obvious in vertical injection molding applications, which can be programmed for post-processing.

Collocating and connecting with robot, it can achieve auto-package for product. The machine adopts double-deck design which fully uses three-dimensional space to place product into container for stacking and packing. Collocated with AGV (Automated Guided Vehicle), it can achieve unmanned logistics.

With compatible sLink technology, it achieves smooth data transmission between the equipments. The whole system manipulates the whole process of injection molding, arranging, stacking, delivering, packaging and the logistics in the production, which is applicable to similar products or assembled products occasions and production besides two IMMs.

Experience Sharing

- Case of Central Water Cooling System-Water Pipe Products

- Case of Central Conveying System in Poland

- Case Studies - Automation Application on Mobile Phone Protective Cover Injection Molding

If you want to read other articles, back to2018 Quarter 3 Issue 36.