Special Reports

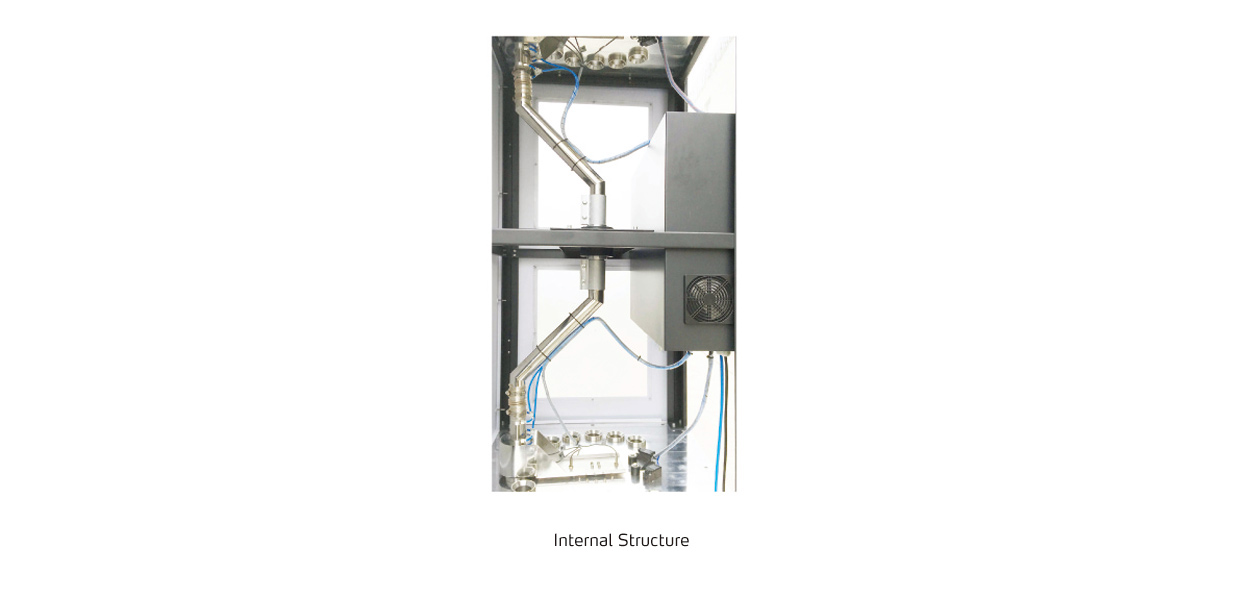

Central Material Distribution Station

Features

1.Vertical design with small footprint that saves the space;

2.Servo motor ensures precise positioning, simple and efficient.

3.The fully automatic operation is achieved through PLC control, and the manual control is also available.

4.Human-friendly interface gives easy operation.

5.Localization monitoring function ensures correct pipe connection.

6.Failure auto alarm function.

7.Fully automatic conveying without operation avoid human mistake and pollution.

8.Remote control function monitors the material source and flow.

9. 1.5’’, 2’’ and 2.5’’ suction pipes are available for the customization.

10. One set of central material distribution station can control 13 material sources and 13 terminals at most, which enables the configuration of one material to any terminal.

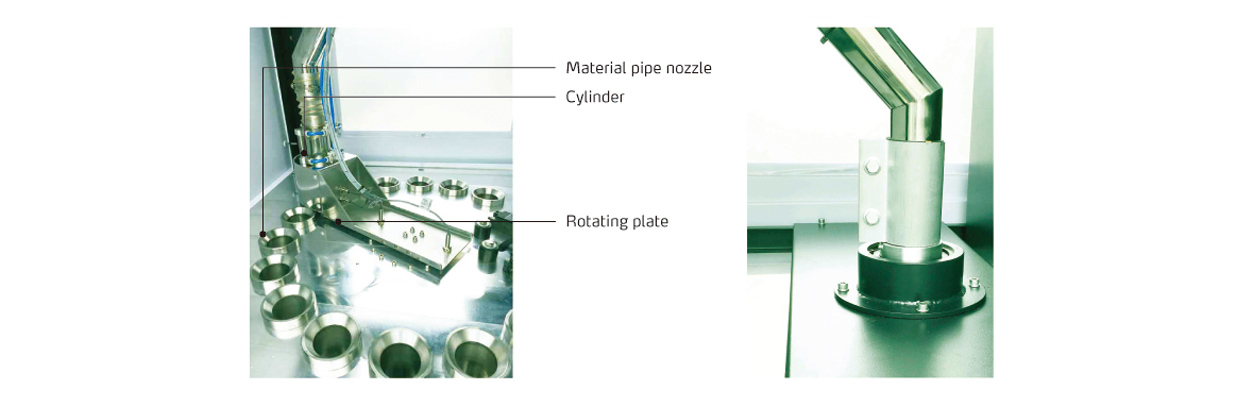

Working Principle

Servo motor drives the rotating plate to the pipe nozzle via the gear box, and the cylinder pushes out the pipe to connect with nozzle that forms the hermitic pipe loop. The upper and lower groups follow the same principle, which forms the closed loop from the material and equipment to convey the material.

Special Reports

- Detachable Silo

- The Application of Hot-runner Valve Multi-cavity System

- The Energy-saving Program of Shini

If you want to read other articles, back to2019 Quarter 1 Issue 38.