Product Improvement

2021 Quarter 2 Issue 43

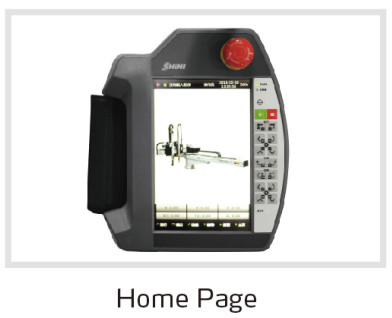

Standard Three-Axis Servo Driven Robot ST3

Features

1. Precision

All linear movements are driven by heavy duty servo motors with cooperation of precise linear guide rails and high power V belts; fast, silent, and precise. Wrist mechanism employs pneumatic driven rack and pinion system, which accomplishes smooth, stabled and precise flipping motion. Vertical arm with telescopic design efficiently minimizes the cycle time and height of the robot.

2. Safety

The travel limit of the X, Y, and Z-axis are with anti-collision devices. It can effectively prevent operation out of control. Complete dual protection function with the soft and hard limit. Ensure the safe operation of injection molding machine and travel robot. The design of I / O short-circuits protection can effectively prevent the circuit board from damage due to an electrical short circuit.

3. Intelligence

7.0 inch high definition TFT touch screen. The USB can be used to upgrade the manual controller and mainboard, download program data, and the open program teaching, 8BG memory, and independent dual 16- bit IO expansion board can expand up to 4 IO boards. The hardware used multi-layer PCB and multi-rank high precision electrical modular, strong anti - interference ability. Hardware protect function, each signal output with intelligent detection, avoid short-circuit, overload and high temperature. Base on the VARAN BUS technology, the system can be extended, strong adaptability and flexibility. Teach modules with stacking and matrix locate functions, support conditional judgment, loop control, signal waiting and others logic instructions.

4. User Friendly

Multi-languages system and reserved auxiliary equipment slots able to support our global clients’ need.

Application

The ST3-S2 series robot is designed for rapid and precise removal of products from injection molding machine, and place them at desired locations. Apply to 2-plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine with clamping force under 3600 tons.