Special Reports

2014 Quarter 3 Issue 20

28th ChinaPlas Ends Completely & Successfully

Overview

Date: 23th May- 26th May 2013

Venue: Shanghai New International Expo Center, PR China

Theme: Greenovation-Solution to Sustainability

Exhibition Contents:

Equipments for plastic and rubber, processing equipments for rubber and quality detecting instruments, plastic products plus plastic films, industrial chemicals for rubber processing, auxiliary materials, molds and accessories for rubber processing, rubber and plastic products.

Exhibition Introduction:

By 2014, the global economy is becoming better and better. However, enterprisers still face a lot of new challenges due to the social contradictions which is caused by raise of labor cost, the shortage of labor force & natural resources, expensive raw material and environment pollution,etc. To cope with the challenges, enterprisers must set up their own competitive advantages, adjust corporate structure and upgrade for transformation. In addition, they should head toward automation, high efficiency, environmental protection and energy conservation & emission reduction.

The 28th CHINAPLAS 2014 which is the first in Asia and the second in the world ended in Shanghai New International Expo Center on April 26th. More than 3000 enterprisers from all over the world participated in this event to display the advanced rubber and plastic technology in the current world. During the 4 days of exhibition, there are more than 130, 000 of audiences from home and abroad going to the show and purchase chemical raw material as well as rubber and plastic machinery.

Events Introduction

The day before the opening of the exhibition, Shini hold a new product release Seminar of 2014 in Shanghai. Shini focused on introducing the new products and new technology to more than 50 distributors of Shini on the Seminar. All contents and words were concise throughout the Seminar. Besides, it also adopted lots of on-spot videos, pictures and dynamic demonstration, which makes it easier for participants to understand. During the whole Seminar, all participants were active and the atmosphere was warm, and thus the conference finally achieved a good effect.

Sharing

The exhibition covers about 22,000 square meters, including 11 big theme zones. There are more than 2,800 exhibitors from 38 countries or regions and 14 groups from different countries or regions. More than 3,200 rubber & plastic machines and chemical raw material which are offered by more than 700 suppliers are displayed. Professional visitors are over 130,000 of which 28% are overseas visitors.

There are many famous auxiliary equipment enterprisers at home and abroad, including Shini, Motan, Piovan, Vermeer, Conair and Songjing, etc.

Along with the exhibition, there were activities of future city and green forum, which enrich the exhibition. The future city activity gave a thorough analysis of science and technology of plastic rubber, how to play an important role in each stage of industrial manufacture as well as in different fields to promote the sustainable development of the industry via abundant information display and fun activities. The green forum covered green molding, three-dimensional printing, plastic recycle and all kinds of schemes about benefiting from solving the waste plastic products.

Spotlight

Informatization

The continuous development of technology, especially the rapid development of information communication technology brings the chance for the industry to improve product performance. Yes, Shini will not miss such an opportunity. The exhibition showed Shini’s ability in the application of new technology and new product development, like the control technology based on Ethernet, industrial water chiller of industrial standard, smart modularization and airflow control technology, and high-speed auto takeout of large plastic products, etc., which all well showed the latest technology of Shini in leading the auxiliary equipment industry.

Smart Modularization and Airflow Control Technology

Modular products are practically widespread in modern industry. They can flexibly meet users’ actual demands with best economic and reasonable way according to their practical needs. We are going to display Shini’s development achievement of modular products in this exhibition. It’s an equipment which is able to realize central dehumidifying and drying of multi materials via. convenient and fast assemble of standard parts.

Auto allocation technology of drying air capacity features that drying air of -40℃ is able to be allocated to each drying hopper automatically according to recipe via. auto control system, which realizes reasonable use of drying air for reducing waste and avoiding over or lacking drying of materials.

“One-to-three” dehumidifying and drying assembly SSMD consists of a rotary dehumidifier and three sets of modular drying hoppers. Those hoppers are set on the floor stand which is modularized assembly. The drying air comes out from the outlet of the rotary dehumidifier and goes out through the main pipe. Then, the drying air is sent to different drying hoppers via. the branches of the main pipe. After finishing drying, hot air will come out from the air exhaust outlet and then go back to the air return pipe. At last, it will go back to the rotary dehumidifier. During this process, this machine is capable of out through the main pipe. Then, the drying air is sent to different drying hoppers via. the branches of the main pipe. After finishing drying, hot air will come out from the air exhaust outlet and then go back to the air return pipe. At last, it will go back to the rotary dehumidifier. During this process, this machine is capable of auto adjustment and allocation. There is an air flow transmitter and air regulator at each branch pipe which enters into drying hoppers. The air flow transmitter is for detecting air capacity changes and sends the related information to the central control unit which controls the air regulator to realize auto adjustment and allocation.

Refrigeration Technology with Industry Standard

For a long time, there is no correspond industry standard for water chillers. Most manufacturers use the refrigerating standard in air conditioner industry for designing water chillers. However, the working condition for water chillers used in industry is always largely different from the one for air conditioners. For example, for general air conditioners only need to work in summer while water chillers need to work steadily all the year round. For all reasons, water chillers produced according to standards of air conditioners is less reliable when applied in industry.

In order to improve the reliability of water chillers and to reduce failure rate of application, we amend the production standard as well as adopt total new internal structure and production technique, which makes them meet the actual demands in the industry environment better. Besides, we have a new type of dedicated controller for the water chiller of new type. The new controller can show the operation information in words directly, which is convenient for the users to watch the operation of the machine.

Integration Control Technology Basing on Ethernet

All new products introduced above have one same feature. They all can realize on-line connection with other industrial controllers. Integration control technology which is based on Ethernet is Shini’s innovative direction for future control system.

This technology can make all control devices which have communication functions connect by network through concentrator. The connecting way is similar to the one of computers. The main control unit realizes central control toward each other controller via. network. Meanwhile, each branch unit can be independently controlled. In other words, users can set the main control unit in the office or at other places for central control. Other branch control unit can be conveniently adjusted on the spot.

Shini displayed a demonstration system particularly in this exhibition. It consists of the control panel from the molding machine and controllers from the auxiliary equipments. In this system, the control panel for the molding machine is the main control unit while the other five controllers from different auxiliary equipments are the branch control units. Therefore, the molding machine is able to centrally control different types of auxiliary equipments.

In addition, Shini works with the main molding machine manufacturer Milacron for systematical demonstration. Milacron provided a set of completely automatic molding machine to Shini. With the cooperation of Milacron, Shini adjust the control program and interface of the standard molding machine by adding a monitor function of auxiliary equipment, which is convenient for users to centrally control all auxiliary equipments on the control panel of a molding machine. By this way, Shini achieved good demonstration effect.

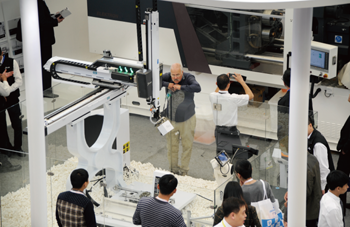

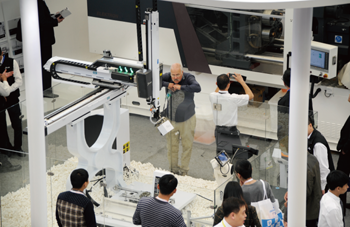

Auto and Fast Take Out of Plastic Products

At the show, Shini displayed the three axes servo driven robot of super high speed SST3-1100-1600 whose dry cycle time can reach to 2.5s at the fastest. It’s suitable for two-plate mold and hot runner mold. It’s capable of all kinds of special actions, like arranging, stacking, quality checking and insertion, etc. The products it takes out should not heavier than 5kg. It has obvious advantages in auto taking out molding products of thin wall.

At the exhibition, Shini adopts a molding machine with hot runner mold to produce small food boxes whose wall thicknesses are 0.5mm. In actual work, the product molding cycle is up to 7.2s. With robot SST3-1100-1600 on the molding machine, the running cycle reaches to 4.5s, which completely meets the requirement of fast take out.

Date: 23th May- 26th May 2013

Venue: Shanghai New International Expo Center, PR China

Theme: Greenovation-Solution to Sustainability

Exhibition Contents:

Equipments for plastic and rubber, processing equipments for rubber and quality detecting instruments, plastic products plus plastic films, industrial chemicals for rubber processing, auxiliary materials, molds and accessories for rubber processing, rubber and plastic products.

Exhibition Introduction:

By 2014, the global economy is becoming better and better. However, enterprisers still face a lot of new challenges due to the social contradictions which is caused by raise of labor cost, the shortage of labor force & natural resources, expensive raw material and environment pollution,etc. To cope with the challenges, enterprisers must set up their own competitive advantages, adjust corporate structure and upgrade for transformation. In addition, they should head toward automation, high efficiency, environmental protection and energy conservation & emission reduction.

The 28th CHINAPLAS 2014 which is the first in Asia and the second in the world ended in Shanghai New International Expo Center on April 26th. More than 3000 enterprisers from all over the world participated in this event to display the advanced rubber and plastic technology in the current world. During the 4 days of exhibition, there are more than 130, 000 of audiences from home and abroad going to the show and purchase chemical raw material as well as rubber and plastic machinery.

The day before the opening of the exhibition, Shini hold a new product release Seminar of 2014 in Shanghai. Shini focused on introducing the new products and new technology to more than 50 distributors of Shini on the Seminar. All contents and words were concise throughout the Seminar. Besides, it also adopted lots of on-spot videos, pictures and dynamic demonstration, which makes it easier for participants to understand. During the whole Seminar, all participants were active and the atmosphere was warm, and thus the conference finally achieved a good effect.

Sharing

The exhibition covers about 22,000 square meters, including 11 big theme zones. There are more than 2,800 exhibitors from 38 countries or regions and 14 groups from different countries or regions. More than 3,200 rubber & plastic machines and chemical raw material which are offered by more than 700 suppliers are displayed. Professional visitors are over 130,000 of which 28% are overseas visitors.

There are many famous auxiliary equipment enterprisers at home and abroad, including Shini, Motan, Piovan, Vermeer, Conair and Songjing, etc.

Along with the exhibition, there were activities of future city and green forum, which enrich the exhibition. The future city activity gave a thorough analysis of science and technology of plastic rubber, how to play an important role in each stage of industrial manufacture as well as in different fields to promote the sustainable development of the industry via abundant information display and fun activities. The green forum covered green molding, three-dimensional printing, plastic recycle and all kinds of schemes about benefiting from solving the waste plastic products.

Spotlight

Informatization

The continuous development of technology, especially the rapid development of information communication technology brings the chance for the industry to improve product performance. Yes, Shini will not miss such an opportunity. The exhibition showed Shini’s ability in the application of new technology and new product development, like the control technology based on Ethernet, industrial water chiller of industrial standard, smart modularization and airflow control technology, and high-speed auto takeout of large plastic products, etc., which all well showed the latest technology of Shini in leading the auxiliary equipment industry.

Smart Modularization and Airflow Control Technology

Modular products are practically widespread in modern industry. They can flexibly meet users’ actual demands with best economic and reasonable way according to their practical needs. We are going to display Shini’s development achievement of modular products in this exhibition. It’s an equipment which is able to realize central dehumidifying and drying of multi materials via. convenient and fast assemble of standard parts.

Auto allocation technology of drying air capacity features that drying air of -40℃ is able to be allocated to each drying hopper automatically according to recipe via. auto control system, which realizes reasonable use of drying air for reducing waste and avoiding over or lacking drying of materials.

“One-to-three” dehumidifying and drying assembly SSMD consists of a rotary dehumidifier and three sets of modular drying hoppers. Those hoppers are set on the floor stand which is modularized assembly. The drying air comes out from the outlet of the rotary dehumidifier and goes out through the main pipe. Then, the drying air is sent to different drying hoppers via. the branches of the main pipe. After finishing drying, hot air will come out from the air exhaust outlet and then go back to the air return pipe. At last, it will go back to the rotary dehumidifier. During this process, this machine is capable of out through the main pipe. Then, the drying air is sent to different drying hoppers via. the branches of the main pipe. After finishing drying, hot air will come out from the air exhaust outlet and then go back to the air return pipe. At last, it will go back to the rotary dehumidifier. During this process, this machine is capable of auto adjustment and allocation. There is an air flow transmitter and air regulator at each branch pipe which enters into drying hoppers. The air flow transmitter is for detecting air capacity changes and sends the related information to the central control unit which controls the air regulator to realize auto adjustment and allocation.

Refrigeration Technology with Industry Standard

For a long time, there is no correspond industry standard for water chillers. Most manufacturers use the refrigerating standard in air conditioner industry for designing water chillers. However, the working condition for water chillers used in industry is always largely different from the one for air conditioners. For example, for general air conditioners only need to work in summer while water chillers need to work steadily all the year round. For all reasons, water chillers produced according to standards of air conditioners is less reliable when applied in industry.

In order to improve the reliability of water chillers and to reduce failure rate of application, we amend the production standard as well as adopt total new internal structure and production technique, which makes them meet the actual demands in the industry environment better. Besides, we have a new type of dedicated controller for the water chiller of new type. The new controller can show the operation information in words directly, which is convenient for the users to watch the operation of the machine.

Integration Control Technology Basing on Ethernet

All new products introduced above have one same feature. They all can realize on-line connection with other industrial controllers. Integration control technology which is based on Ethernet is Shini’s innovative direction for future control system.

This technology can make all control devices which have communication functions connect by network through concentrator. The connecting way is similar to the one of computers. The main control unit realizes central control toward each other controller via. network. Meanwhile, each branch unit can be independently controlled. In other words, users can set the main control unit in the office or at other places for central control. Other branch control unit can be conveniently adjusted on the spot.

Shini displayed a demonstration system particularly in this exhibition. It consists of the control panel from the molding machine and controllers from the auxiliary equipments. In this system, the control panel for the molding machine is the main control unit while the other five controllers from different auxiliary equipments are the branch control units. Therefore, the molding machine is able to centrally control different types of auxiliary equipments.

In addition, Shini works with the main molding machine manufacturer Milacron for systematical demonstration. Milacron provided a set of completely automatic molding machine to Shini. With the cooperation of Milacron, Shini adjust the control program and interface of the standard molding machine by adding a monitor function of auxiliary equipment, which is convenient for users to centrally control all auxiliary equipments on the control panel of a molding machine. By this way, Shini achieved good demonstration effect.

Auto and Fast Take Out of Plastic Products

At the show, Shini displayed the three axes servo driven robot of super high speed SST3-1100-1600 whose dry cycle time can reach to 2.5s at the fastest. It’s suitable for two-plate mold and hot runner mold. It’s capable of all kinds of special actions, like arranging, stacking, quality checking and insertion, etc. The products it takes out should not heavier than 5kg. It has obvious advantages in auto taking out molding products of thin wall.

At the exhibition, Shini adopts a molding machine with hot runner mold to produce small food boxes whose wall thicknesses are 0.5mm. In actual work, the product molding cycle is up to 7.2s. With robot SST3-1100-1600 on the molding machine, the running cycle reaches to 4.5s, which completely meets the requirement of fast take out.

Special Reports

If you want to read other articles, back to2014 Quarter 3 Issue 20.