New Product Launch

2014 Quarter 3 Issue 20

Application of Shini sLink Protocol Solution

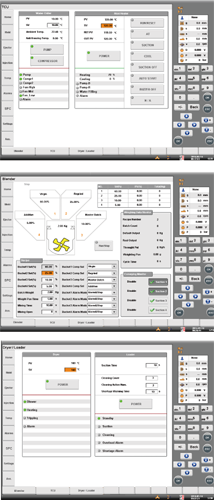

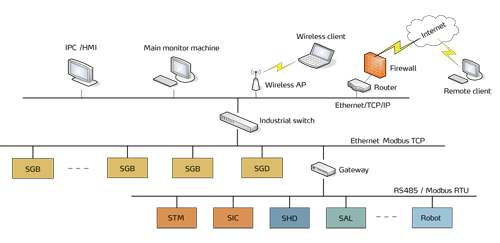

With the development of Internet technology, industry control has already developed from single machine control into the distributed control system which is based on Internet communication. It can realize distributed control, central display and control function of both independent and central control. Shini sLink Protocol Solution is the central monitor solution of plastics auxiliary equipment based on Ethernet. This technology can get all auxiliary equipments which have communication function in one network. The main control machine can monitor the state of the remote auxiliary equipments and get data via. Internet. The operator also can control each machine independently via. the control panel of the machine.

Controllers of Shini plastics auxiliary equipment possess Ethernet and network port RS485 (Some models of machine requires a network port.). It adopts industrial communication protocol Modbus which is commonly used all over the world to communicate. Since Modbus is a communication protocol of open type and the most common industry standard, it is supported by the PLC, HMI and the configuration software of most manufacturers. Therefore, Shini auxiliary equipment can be easily connected to form the monitor network or integrated into the existing monitor system.

Shini worked together with a famous injection molding machine manufacturers Milacron to develop an injection molding machine control system (BnR) which possesses both auxiliary equipment and injection molding functions. Integrate the monitor functions of Shini gravimetric blender, water chiller, temperature controller, dryer, loader and robot into the injection molding control system via. Ethernet and RS485, which realizes to monitor the working state of injection molding machine and different types of auxiliary equipments and thus improves working performance and equipment management level.

New Product Launch

- Shini Launches Modular Dryer SSMD-U

- Energy-saving Hopper Dryer SHD-EH

- Bridge-breaking Hopper SBH

- Shini Blowing Machine in Molding Labeling SBI

- Mold Clamps

- Anti-vibration Pads

If you want to read other articles, back to2014 Quarter 3 Issue 20.