Experience Sharing

Application of Automation in Chemical Filler Industry

Chemical

filler is the essential component of gas-liquid contact in the packing tower,

featuring excellent acid and heat resistance properties. It is highly resistant

to corrosion of all kinds of inorganic acids, organic acids, and organic

solvents except the hydrofluoric acid. It is known for a wide range of

applications, such as in drying tower, absorption tower, washing tower and

regeneration tower of chemical, metallurgy, and gas oxygen industries. The

material can be classified as ceramic filler, plastic filler, and metal filler.

Enterprises are the main bodies of market economic activities. To become a

player in the fierce market competition, we must try our best to improve our

competitiveness.

A

Technology Co., Ltd. in Jiangxi has established a digital production base of 5G

technology + intelligent manufacturing, the first digital chemical company in

China's mass transfer material industry. The new materials demonstration

enterprise of technologic 5G intelligent manufacturing mainly produces mass

transfer materials and industrial equipment. As a professional manufacturer of

mass transfer materials, it has developed more than 100 kinds of products, such

as plastic filler, metal filler, ceramic filler, packed tower and other mass

transfer equipment, tower internals, trays, vessel towers, fire pipelines, new

fire-fighting materials, water treatment materials and so on. All products have

independent intellectual property rights and are widely used in mass transfer

processes of the chemical, fertilizer, coking, chlor-alkali, salinization,

electric power, environmental protection, oil refining, coal to liquids,

pharmaceutical, fire-fighting, and other industries. The company became the

partner of Shini in 2017 and purchased several batches of the Three Axes Servo

Driven Robots from Shini for automatic injection molding of the plastic filler

products. After the equipment was put into use, the robots ran stably.

Moreover, they worked well with the injection molding machine, thus significantly

improving the productivity and quality.

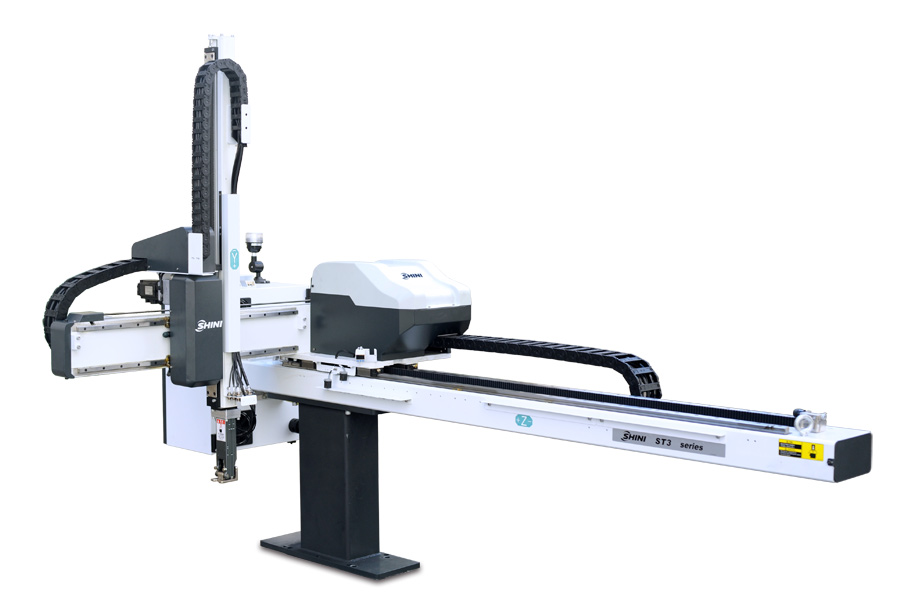

The

series of Three Axes Servo Driven Robots are mainly used for removing prues and

finished products in the injection molding process. There are single-arm and

double arms choices to apply with two plate mold, three plate mold, or hot

runner mold plate. It complies with the industry 4.0 standard, capable of

arranging, stacking, quality, and mold placement. It is suitable for injection molding

machines with clamping force under 3600 tons.

Three Axes Servo Driven Robot

Experience Sharing

- The Case of Whole Plant Planning in Protective Appliances Industry

- The Application of Central Material Processing System in Food Packaging Industry

If you want to read other articles, back to2021 Quarter 1 Issue 42.