Experience Sharing

2022 Quarter 3 Issue 48

Energy Efficient, Smart Modular Dehumidifying Dryer

For the drying and dehumidifying equipment, the drying air quantity plays an essential role in the drying process, and suitable air quantity can help the materials achieve the best drying effect, thus avoiding defective or over-drying materials. The demand for drying air quantity varies with different materials. If a specific material can be dried without the complete air quantity, properly controlling the air quantity can reduce the pipe heater's working time. It means power consumption and the blower's energy consumption can be reduced. Thus, giving proper drying air quantity to the materials can get a good drying effect and save energy.

Smart Modular Dehumidifying Dryer SSMD

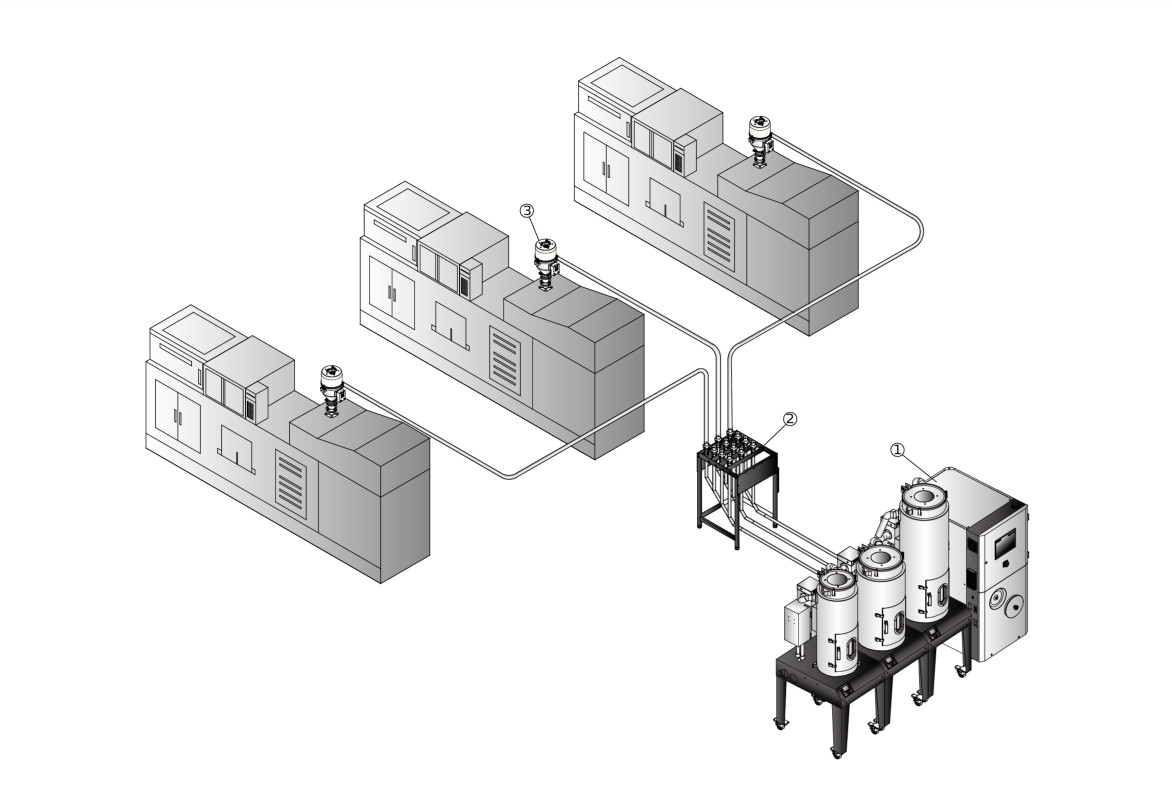

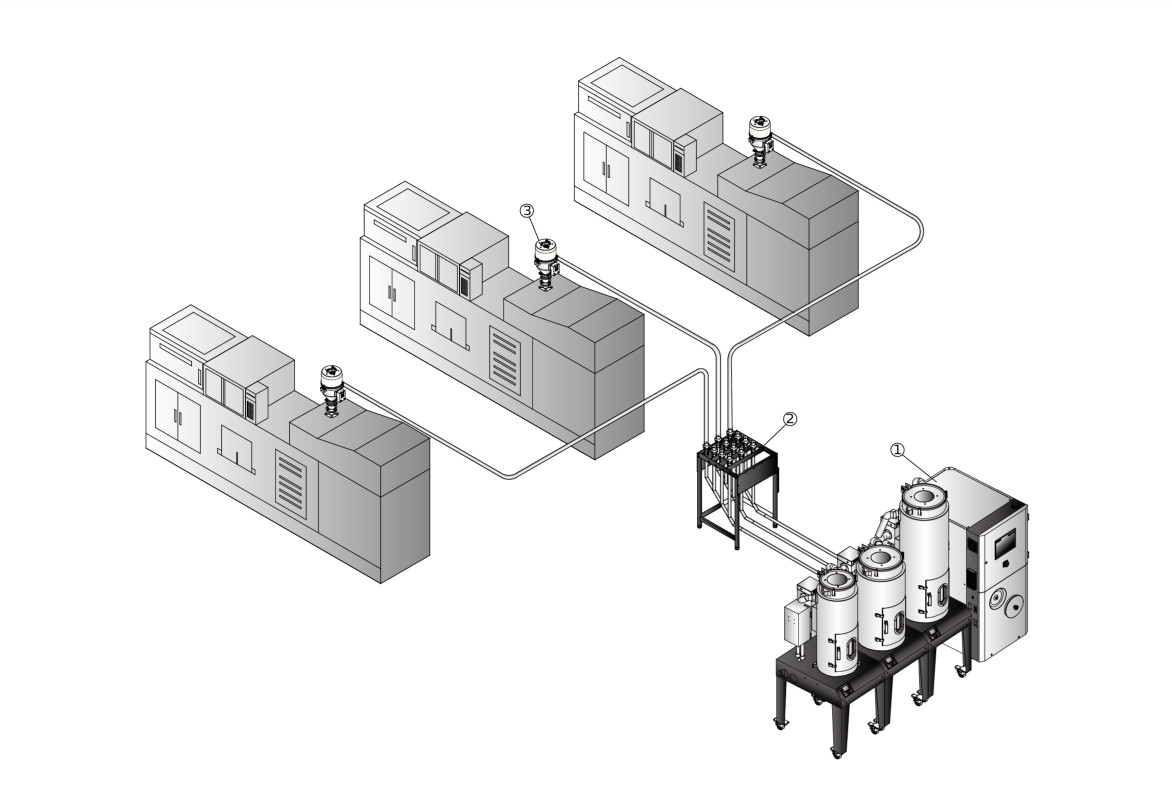

Auto distribution of the drying air quantity on demand Modules of the honeycomb rotor SD-H-SM and modular hopper dryer MHD-U commonly combine the smart modular dehumidifying dryer. Each hopper's drying air pipeline and electrical circuits can be easily connected with the dehumidifier, thus improving the equipment's mounting installation efficiency. It adopts the technology of auto distributing the drying air quantity on demands, which features -40℃ dew-point drying air that can automatically be distributed to each drying hopper by the auto control system as a requirement to achieve proper use of the dry air, reducing wastes and preventing over or insufficient drying of the materials. Besides, each hopper's drying temperature can also be controlled independently.

Modular assembly & flexible collocation

A modular combination makes it much easier to expand the capacity later. When drying several kinds of plastics at one time, it also can achieve flexible configuration based on the hopper capacity. All the drying air piping systems are built into that, ensuring clean modular stands and simple installation.

Application

case

case

Dehumidifier:SD-200H-SM4

Modular drying hopper:MHD-80U*2、MHD-160U

Plastics:PC、ABS、PS

case

case Dehumidifier:SD-200H-SM4

Modular drying hopper:MHD-80U*2、MHD-160U

Plastics:PC、ABS、PS

Application

Experience Sharing

- Smart Home Appliance Industry with touch of Automated Solution

- Centralize Material Processing Systems in Photovoltaic Industry

If you want to read other articles, back to2022 Quarter 3 Issue 48.