New Product Launch

2023 Quarter 4 Issue 52

Shini Self-adaption Energy-saving Hopper Dryer SHD-E-EC

The shortage of electricity resources and energy is a crucial factor restricting China's economic development, so saving electricity is a basic national policy for China’s social economic sustainable development. With the continuous improvement of people’s life quality, the demand for plastic products is also increasing, and the requirements of plastic material’s drying and dehumidifying process becomes even stricter, thus accelerating the development of corresponding drying and dehumidifying technologies. Also, to better adapt to the trend of energy conservation and environmental protection, manufacturers are trying their best to improve the energy-saving efficiency of the drying and dehumidifying process, and more and more customers are willing to purchase the energy-saving models. For this, Shini launched the self-adaption energy-saving hopper dryer SHD-E-EC series that nicely meets such market demands.

Self-adaption Energy-saving Hopper Dryer

The self-adaption energy-saving hopper dryer adopts the variable frequency speed regulation technology with a built-in 28 recipes function, and customers can set appropriate recipes based on the current material type. The equipment can work automatically to adjust the blower speed (the minimum can be reduced to 20Hz) and the pipe heater output based on the real-time status of the present exhaust air and set exhaust air temperature to achieve energy-saving and drying effect. After the material pre-drying, if the plastic materials are not in use for a long time, the drying temperature will decrease as needed automatically, and the machine will enter the insulation state to prevent the material from excessive drying while saving energy. The self-adaption energy-saving hopper dryer also has an adaptive mode, so the user only needs to set the drying temperature, and the system will automatically configure the exhaust air temperature for simple operation.

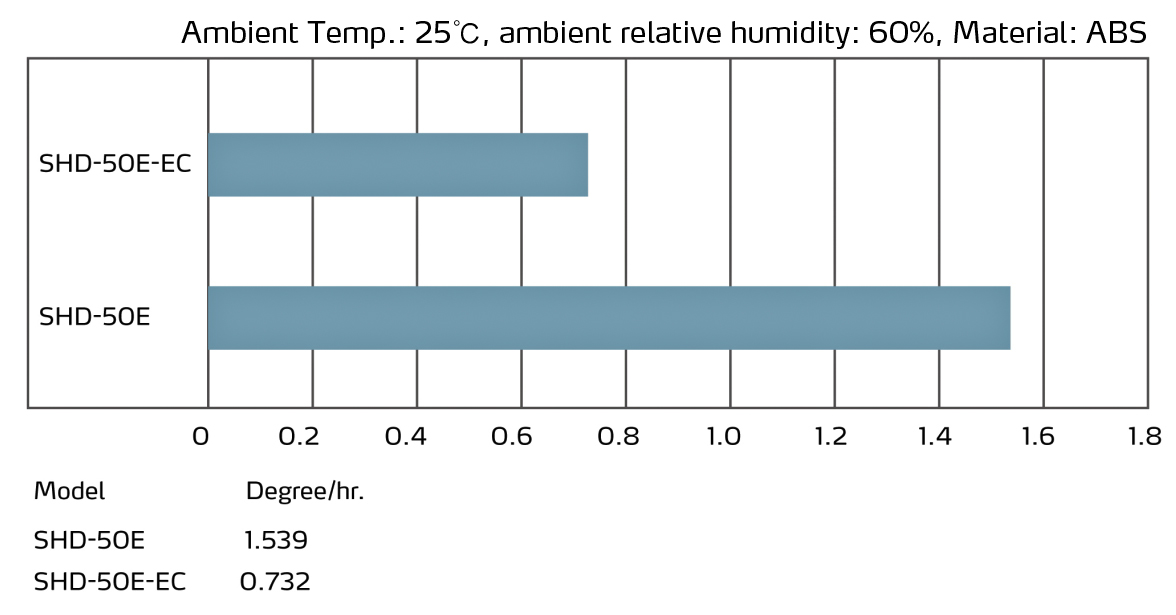

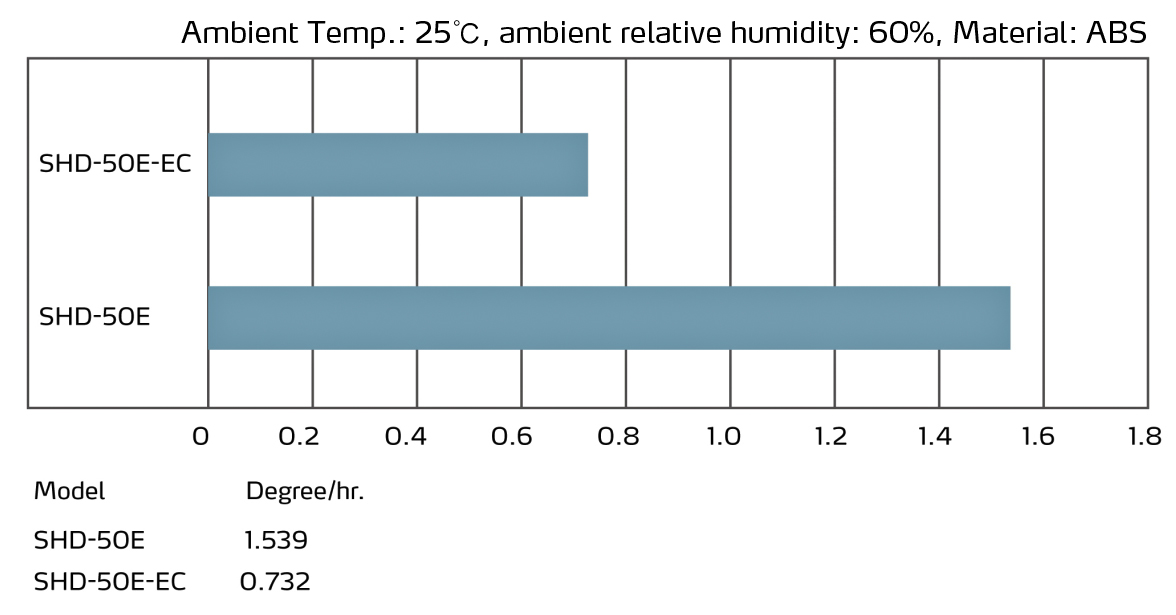

Under different conditions, the SHD-E-EC can save up to 30% to 80% of power compared to standard hopper dryers, with significant energy-saving effects.

Features

Self-adaption Energy-saving Hopper Dryer

The self-adaption energy-saving hopper dryer adopts the variable frequency speed regulation technology with a built-in 28 recipes function, and customers can set appropriate recipes based on the current material type. The equipment can work automatically to adjust the blower speed (the minimum can be reduced to 20Hz) and the pipe heater output based on the real-time status of the present exhaust air and set exhaust air temperature to achieve energy-saving and drying effect. After the material pre-drying, if the plastic materials are not in use for a long time, the drying temperature will decrease as needed automatically, and the machine will enter the insulation state to prevent the material from excessive drying while saving energy. The self-adaption energy-saving hopper dryer also has an adaptive mode, so the user only needs to set the drying temperature, and the system will automatically configure the exhaust air temperature for simple operation.

Under different conditions, the SHD-E-EC can save up to 30% to 80% of power compared to standard hopper dryers, with significant energy-saving effects.

Features

- Adopt a hot air diffuser to keep plastics dry and temperature stable, thus improving drying efficiency.

- All material contact surfaces are made of stainless steel to eliminate material contamination.

- All models are equipped with external power switch.

- For SHD-25E-EC~150E-EC, heater pipes are connected by lead sheets and other models are equipped with temperature protector to prevent heater pipe from damaging by blower fault.

- When the actual drying temperature exceeds the set value, the system will cut off the heater power automatically, and the alarm light will flicker and alarm.

- Adopt a heat-insulated blower to prolong the blower's lifespan.

- All models are standard equipped with a 7-day timer and intermittent operation.

- All series are equipped with microcomputer control.

- Max. drying temperature is 160℃.

- The series of blowers are equipped with overheat protector.