Special Reports

2015 Quarter 2 Issue 23

Working Principle and Practical Implication of Cyclone Separator

Cyclone separator is a kind of equipment used in air-solid separation. At the end of the air conveying system, it acts as the separator for granule in the conveying air. It is a kind of purifying equipment features simple structure, convenient maintenance,high-temperature resistance which has low costs and high resistance. It has no movable parts which the service life is much longer than common filter. Therefore, the cyclone separator is widely used in plastic materials granulating and recycling as well as dust-removing in exhausted drying air.

Ordinarily, cyclone separator is manufactured by welding of common steel plate, and is applicable for occasions requiring less air purity relatively. If there needs high standard of air purity, the adopting of electrolytic or stainless steel plate in process can meet the requirement.

Working Principle

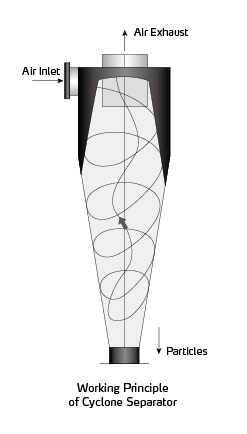

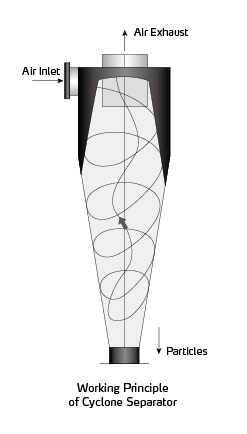

Cyclone separator utilizes cyclone centrifugal force to separate granules from the air. As the below picture, granules containing air firstly enter the inner cyclone separating area of the hopper through inlet. In this area, direction of air is changed from direct entering to down-run with spiral rotating along the screw (as solid line). The high-density dust particles are dragged to hopper lining by centrifugal force. With the air rotating along the screw and the entering of cone part, spiral airflow inside the hopper flows to the center as hopper diameter reduced. In lessened centrifugal force, granules are exhausted along inside hopper to the outlet. However the secondary vortex flow will be formed when airflow reaches the ending part of the cone hopper and will be expelled via upper exhausting pipe of the cone part.

Pressure Loss

There are varies proportions and styles of the cyclone separator, which generate different pressure losses. Usually, pressure loss of the cyclone separator is about 50~200mmAq.

When cyclone separator is used in positive pressure conveying system, with the large conveying pressure, even there’s much pressure loss of the cyclone separator, it just makes a little influence on the conveying effect. We generally attach more attention to the separation effect.

In negative pressure conveying system, the air-source equipment usually has low suction pressure, the less pressure loss of cyclone separator, the better. In designing of the cyclone separator, it should estimate its pressure loss precisely, and calculate the output pressure of the air-source equipment.

Separation Effect

Ordinarily, the cyclone separator is applicable to separate the non-viscous, non fiber dry dust greater than 1-3 micrometers. By accurate calculation and appropriate technological structure, it can get supreme separation effect eventually. For large size granules, the separating rate can reach above 97%. The granule in smaller size or is more light, the more difficult to separate effectively.

Application

Currently, the cyclone separators are widely used in Shini products, they always appear in the occasions which need air-solid separation. The products include HCF Cyclone Dust Separator, ACF Cyclone Dust Collector, Blower Conveying & Cyclone Dust Collector of Shini Granulator and the conveying device of Shini Sound-proof Central Granulator.

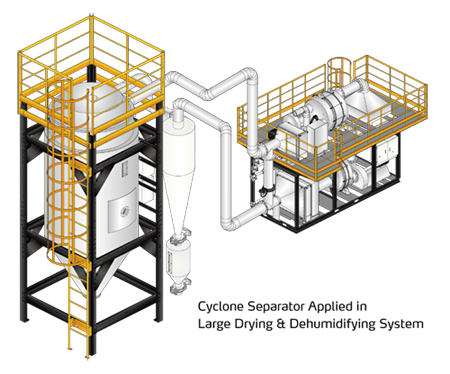

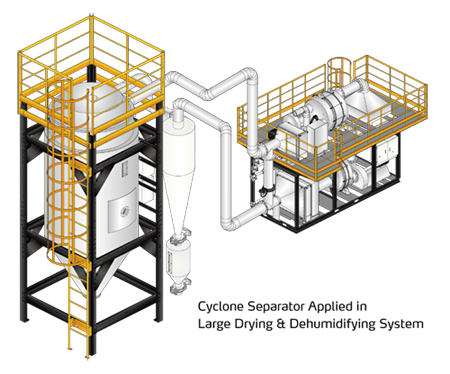

For some plastic materials, like PET or others, during process of pre-crystallizing, drying and dehumidifying, and conveying, which contain the granules or much granules generated by friction. If there’s no pre-separation for granules in the drying air of return loop or in the conveying recycling process, it will block the return-air filter or the front-set filter soon, and affect the ventilation which eventually influences the material drying and conveying capacity. Especially for large drying and dehumidifying or conveying system, granules containing airflow will affect the filter seriously. Therefore, before drying air return or conveying air passing through the filter, make it get through the cyclone separator at first can lessen filter’s cleanliness and improve the operating efficiency.

Ordinarily, cyclone separator is manufactured by welding of common steel plate, and is applicable for occasions requiring less air purity relatively. If there needs high standard of air purity, the adopting of electrolytic or stainless steel plate in process can meet the requirement.

Working Principle

Cyclone separator utilizes cyclone centrifugal force to separate granules from the air. As the below picture, granules containing air firstly enter the inner cyclone separating area of the hopper through inlet. In this area, direction of air is changed from direct entering to down-run with spiral rotating along the screw (as solid line). The high-density dust particles are dragged to hopper lining by centrifugal force. With the air rotating along the screw and the entering of cone part, spiral airflow inside the hopper flows to the center as hopper diameter reduced. In lessened centrifugal force, granules are exhausted along inside hopper to the outlet. However the secondary vortex flow will be formed when airflow reaches the ending part of the cone hopper and will be expelled via upper exhausting pipe of the cone part.

There are varies proportions and styles of the cyclone separator, which generate different pressure losses. Usually, pressure loss of the cyclone separator is about 50~200mmAq.

When cyclone separator is used in positive pressure conveying system, with the large conveying pressure, even there’s much pressure loss of the cyclone separator, it just makes a little influence on the conveying effect. We generally attach more attention to the separation effect.

In negative pressure conveying system, the air-source equipment usually has low suction pressure, the less pressure loss of cyclone separator, the better. In designing of the cyclone separator, it should estimate its pressure loss precisely, and calculate the output pressure of the air-source equipment.

Separation Effect

Ordinarily, the cyclone separator is applicable to separate the non-viscous, non fiber dry dust greater than 1-3 micrometers. By accurate calculation and appropriate technological structure, it can get supreme separation effect eventually. For large size granules, the separating rate can reach above 97%. The granule in smaller size or is more light, the more difficult to separate effectively.

Application

Currently, the cyclone separators are widely used in Shini products, they always appear in the occasions which need air-solid separation. The products include HCF Cyclone Dust Separator, ACF Cyclone Dust Collector, Blower Conveying & Cyclone Dust Collector of Shini Granulator and the conveying device of Shini Sound-proof Central Granulator.

For some plastic materials, like PET or others, during process of pre-crystallizing, drying and dehumidifying, and conveying, which contain the granules or much granules generated by friction. If there’s no pre-separation for granules in the drying air of return loop or in the conveying recycling process, it will block the return-air filter or the front-set filter soon, and affect the ventilation which eventually influences the material drying and conveying capacity. Especially for large drying and dehumidifying or conveying system, granules containing airflow will affect the filter seriously. Therefore, before drying air return or conveying air passing through the filter, make it get through the cyclone separator at first can lessen filter’s cleanliness and improve the operating efficiency.

Special Reports

- Industrial Water Chiller COP Introduction & the China Standard

- The PET Crystallizer SCR Improvement

- RS485 Communication Interface Applied in Mould Temperature Controller

- Conveying Control Differences between SHR-U-(E) S Applied on SGB and Other Machine

- Application of SICH-U Insulated Collective Hopper

- In What Circumstance to Use Hot-runner

- About Shini Europe

If you want to read other articles, back to2015 Quarter 2 Issue 23.