Special Reports

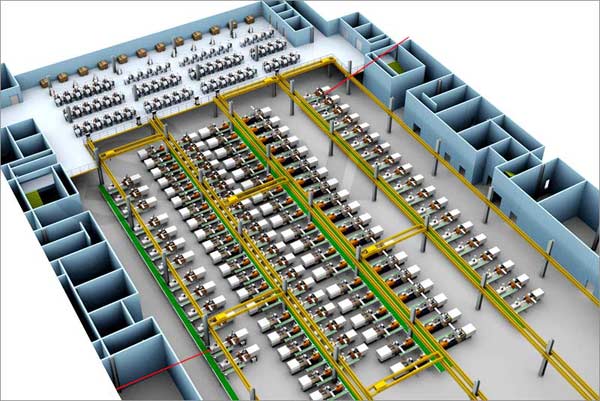

Central Material Conveying System

1.Storage

For material storage, Shini can provide you with large scale silos which are suitable for outdoor application, and small sized material tanks for regrinds and masterbatch materials. When container bags are used, Shini can also provide you with relevant discharging and storage equipments.

Real-time monitoring of material level makes operation much more convenient.

Large-scale silos used outside to store materials, with a maximum storage of 100 tons of materials.

Large-scale silos placed inside for storing materials, with a maximum storage of 6 tons of materials.

New round silos, with protective ladder being optional.

They are used for storing materials and can be placed inside material room or beside IMM; they can also work with granulators, storing the materials conveyed by the granular for a short period.

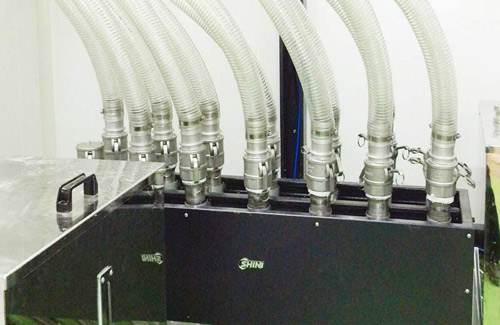

2.Distributor

SMDS distributes materials to their corresponding storage hoppers in the system, and there are five models of the SMDS. All of them are equipped with quick couplers that make loading and unloading easy and are made of stainless steel which prevents materials from contamination.

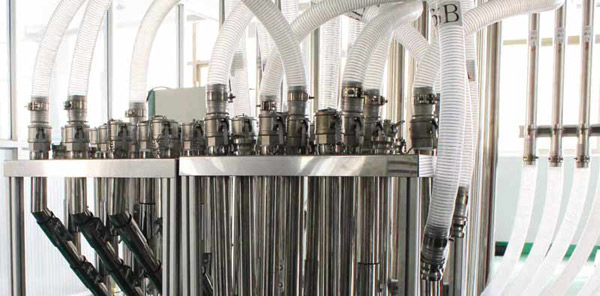

3.Convey

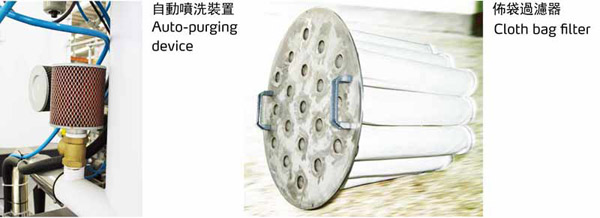

In the central conveying system, SCVG provides vacuum (negative pressure) power. This heavy-duty machine adopts high-pressure blower or roots blower as its power core, enjoying several advantages including great power, long service life, etc, so that continuous conveying can be achieved.

SCSF uses large-scale filter to filter the dust and tiny impurities in materials. Therefore, the blower gets well protection and then its service life can get lengthened.

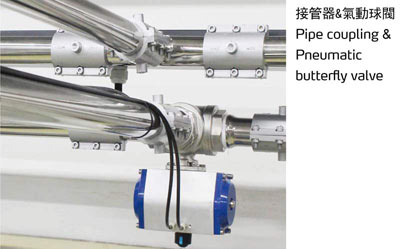

It adopts stainless steel pipe, which is durable and can protect materials from contamination.

4.Molding

From material-supply room to IMM, all relevant pipes in the workshop are well arranged and in good order. What’s more, with engineer’s ingenuity, the air outlet of IMM is connected with the air pipe via a short flexible pipe, achieving a smooth connection and making the whole system look integrated.

Special Reports

- The Significance of COP to Cooling System

- The Usage of Heatless Air Dryer

- Vertical Rotary Discharge Valve LRV40

If you want to read other articles, back to2017 Quarter 4 Issue 33.