New Product Launch

2018 Quarter 2 Issue 35

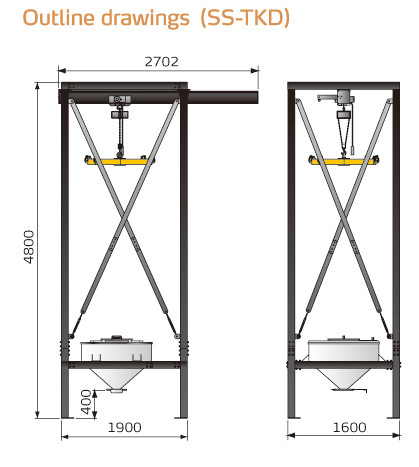

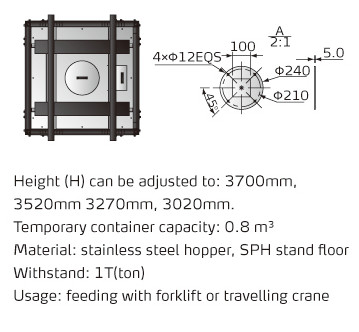

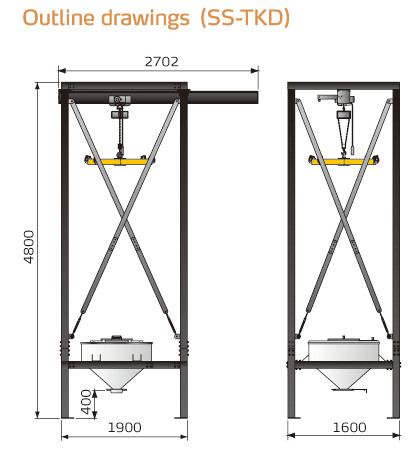

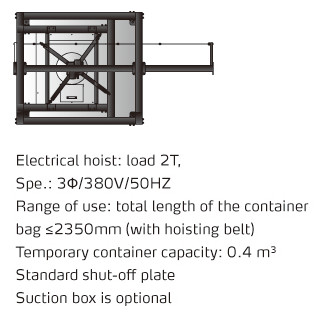

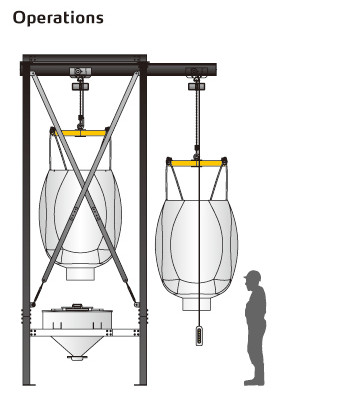

Container Bag Discharge Station

Application

The container bag discharge station is used for discharging and conveying of materials from the container bag in the plant; With simple operation, its bottom can mount the suction box for production line conveying or silo feeding; which also can install the optional rotary valve and acceleration chamber to feed the large silo.

New Product Launch

If you want to read other articles, back to2018 Quarter 2 Issue 35.