Special Reports

2017 Quarter 1 Issue 30

Explanation of Hot-runner Technology

Hot Runner Assembly

Hot-runner system consists of hot runner manifold board, nozzle and high-precision temperature controller. The same mould has single or multiple nozzles models, in which the manifold board is the most important element. First of all, let’s mainly talk about the manifold.

Manifold Board

Functions: Connect nozzle of injection molding machine with hot nozzles, and keep constant temperature of plastics from injection molding machine through each nozzle.

Functions: Connect nozzle of injection molding machine with hot nozzles, and keep constant temperature of plastics from injection molding machine through each nozzle.

Features: It makes evenly fill the cavity of mould, balance flow of plastics and system balance heat.

Classification: It has I, H, X models according to the outline, and heating pipe, rod models according to heating method.

Balance Design of Manifold Board

For design of regular arrangement of multiple cavity products, it should adopt balance design (including fully-balanced runner and heating).

Manifold board with smooth runner wall and no dead angle can quick change the color.

1. Manifold board wall of Shinzo hot runner adopts fluid polishing, ensuring smooth wall without dead angle;

2. Plugs at runner corner adopts smooth transition, and the special position adopts mosaic structure, ensuring smooth corner.

Manifold board after special processing is color replaceable and durable

The processing of manifold board determines if it’s easy to change color and life service, and the life service can be ensured by following method:

Adopt special deep-hole drill to drill runner holes. Use below two corner-processing methods according to different materials and requirements.

Plug mode (a): simple structure, most commonly used one;

Insert mode (b): complex structure, for color changing and transparent materials without glue and yellowing problems;

1.The runner adopts special polishing (high-pressure diamond fluid), ensuring the consistency of runner size. Wall surface finish could reach 0.8 below, which ensures the balance of whole hot runner.

2.For manifold board of molding high-corrosion (PVC) and fiber reinforced materials (+50GF), it adopts heating to improve abrasive resistance;The inner hole after special coating has 3 time life service than common types.

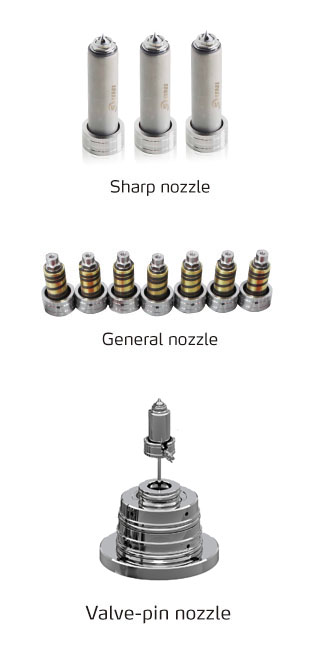

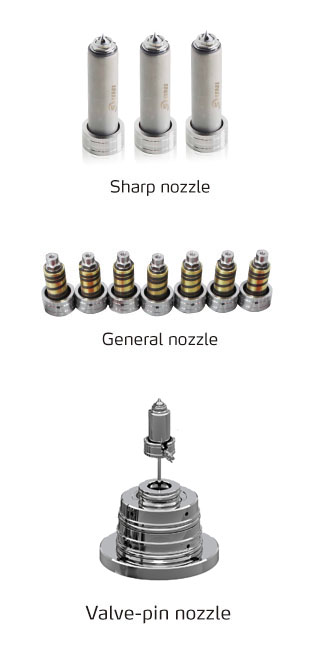

Nozzle Introduction

Functions: feed plastics through manifold board into each cavity sufficiently.

Features: with reduced pressure loss, balanced plastics flow, aesthetic gate and no marked sprue;

Types: it sharp nozzle, general nozzle and valve-pin nozzle according to structure

Temp.-controller Introduction

Functions: the temperature controller is an instrument controlling temperature of each position of hot-runner system.

Features: accurate and high-precision signal, and has J,K modes, with temperature accuracy reaching ±0.5℃/0.9oF.

Types: dial style, odometer and microcomputer intelligent modes of temp. controller etc.

Application

Product:nursing bottle

Material:PPSU

Weight:50G

Cavity:1X12

This transparent product is easily suffered carbonized silver streak, bubble, whitening and dark spot. For the solution, our company developed balance design of hot runner selects special Hotset heater and pin-valve parameter and standard, which extensively applying in packages and daily necessities.

Hot-runner system consists of hot runner manifold board, nozzle and high-precision temperature controller. The same mould has single or multiple nozzles models, in which the manifold board is the most important element. First of all, let’s mainly talk about the manifold.

Manifold Board

Features: It makes evenly fill the cavity of mould, balance flow of plastics and system balance heat.

Classification: It has I, H, X models according to the outline, and heating pipe, rod models according to heating method.

Balance Design of Manifold Board

For design of regular arrangement of multiple cavity products, it should adopt balance design (including fully-balanced runner and heating).

Manifold board with smooth runner wall and no dead angle can quick change the color.

1. Manifold board wall of Shinzo hot runner adopts fluid polishing, ensuring smooth wall without dead angle;

2. Plugs at runner corner adopts smooth transition, and the special position adopts mosaic structure, ensuring smooth corner.

Manifold board after special processing is color replaceable and durable

The processing of manifold board determines if it’s easy to change color and life service, and the life service can be ensured by following method:

Adopt special deep-hole drill to drill runner holes. Use below two corner-processing methods according to different materials and requirements.

Plug mode (a): simple structure, most commonly used one;

Insert mode (b): complex structure, for color changing and transparent materials without glue and yellowing problems;

1.The runner adopts special polishing (high-pressure diamond fluid), ensuring the consistency of runner size. Wall surface finish could reach 0.8 below, which ensures the balance of whole hot runner.

2.For manifold board of molding high-corrosion (PVC) and fiber reinforced materials (+50GF), it adopts heating to improve abrasive resistance;The inner hole after special coating has 3 time life service than common types.

Nozzle Introduction

Functions: feed plastics through manifold board into each cavity sufficiently.

Features: with reduced pressure loss, balanced plastics flow, aesthetic gate and no marked sprue;

Types: it sharp nozzle, general nozzle and valve-pin nozzle according to structure

Features: accurate and high-precision signal, and has J,K modes, with temperature accuracy reaching ±0.5℃/0.9oF.

Types: dial style, odometer and microcomputer intelligent modes of temp. controller etc.

Material:PPSU

Weight:50G

Cavity:1X12

This transparent product is easily suffered carbonized silver streak, bubble, whitening and dark spot. For the solution, our company developed balance design of hot runner selects special Hotset heater and pin-valve parameter and standard, which extensively applying in packages and daily necessities.

Special Reports

If you want to read other articles, back to2017 Quarter 1 Issue 30.