Special Reports

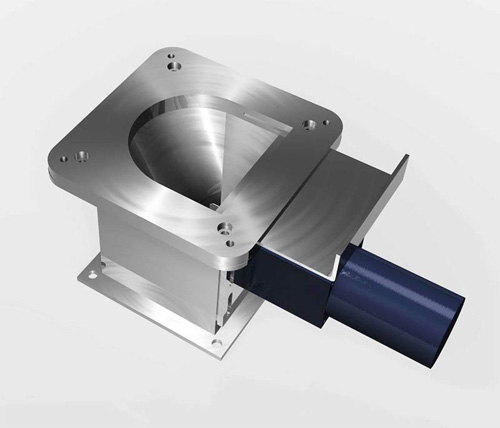

Dust Separators SDS-500

Features

1.Secondary air inlet is designed for airflow regulation;

2.Easily removed and is convenient for installation and operation.

3.All material contacted surfaces are made of stainless steel ensure no material contamination.

4.Equip with adjusting motor for discharge to adjust discharging speed according to actual demands.

5.High-speed static eliminator quickly neutralizes static electricity on the surface of material.

6.Filter and dust collective hopper are convenient for dust recycling to protect blower free of damage.

7.SDS-500 has alarm indicator for quick fault indicating.

8.SDS-500 has material loading blower and photo-sensor hopper to perform automatic material loading.

9.The efficiency of dust separating can reach 80%.

10.Storage tank is optional (with level motor and suction box).

Key Improvements

1.Adopt air-shower flow to remove dust in materials or granules, and punch air hole on each material fender to improve de-dusting efficiency.

2.Adjustable discharge port controls the discharge amount that improves de-dusting efficiency.

Application

SDS is suitable for powder removing of various materials, such as PET, PC, PA etc.

Special Reports

- Application of SCAD Used in 3D Printing

- “One-to-Two” Compact Dryer

- “Large Flow” Water Heater STM-WFN

- Side Entry Robot

- Application of Valve Hot Runner

- Case Study of Pneumatic Conveying System

- My Shini Life

If you want to read other articles, back to2017 Quarter 2 Issue 31.