Special Reports

2017 Quarter 2 Issue 31

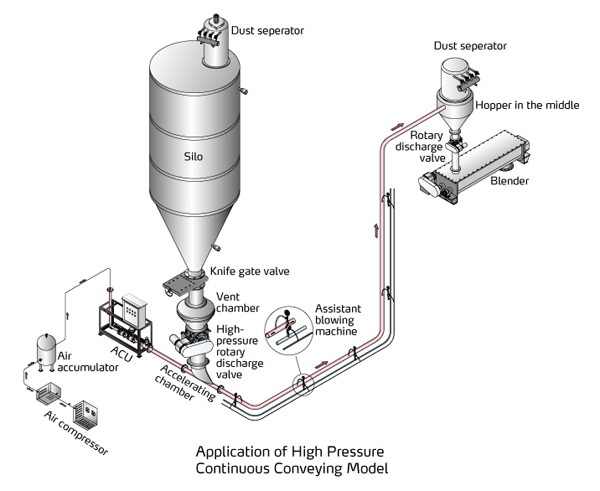

Case Study of Pneumatic Conveying System

Concept of Pneumatic Conveying

Pneumatic conveying uses air pressure to convey bulk materials through the pipeline.

Pneumatic Conveying Features

1.Easy installation with layout flexibility.

2.Material flows in closed pipeline without dust leakage and environmental pollution.

3.Fulfill various operations during conveying simultaneously, such as mixing, dosing, classification, packaging and de-dusting.

4.Materials are free of damping, contamination, debris and artificial intervention during conveying, ensuring product quality.

5.Adopt special protective gas in closed circulation to convey flammable and combustible materials, improving system safety.

6.Less cost on packaging, assembling and disassembling.

7.Achieve continuous or discontinuous conveying, multi-point feeding and discharging, flexible plans and extensive options.

8.Little movable parts in high reliability require simple maintenance.

9.High automation level is suitable for continuous production.

ACU Air Control Unit

ACU (Air Control Unit) features high efficient and low consumption that is suitable for large material flow. And with the assistance of modern technology, it plays an important role in pneumatic conveying. High concentration and low speed continuous conveying largely reduces material crushing probability during the process. Besides, real-time transmission of conveying pressure and auto control the opening of control valve greatly reduces air consumption.

Application

Chemical, Food, Rubber and Plastics, Electronics, Medicine, Steel, Environmental Protection and Power Generation

Applicable Materials

PET, BPA, PTA, PBT, SAP, PP, PE, ABS, PS, HDPE, LLDPE, PET, BPA, PTA, PBT, SAP, PP, PE, ABS, PS, HDPE, LLDPE, EVA, Potato Starch, Calcium Carbonate, Kaolin, Barium Sulfate, Talcum Powder, Mica, Silicon Carbide, Flour, Starch and Sugar, etc.

Outstanding Characteristics

Low operating and maintenance costs; less cost on equipment space and excellent conveying quality; Data digitized transmission, conveniently intelligent operation. Optimal conveying conditions can be set according to conveying distance and physical property. User-friendly auto feedback mechanism is able to adjust the conveying till its optimal conditions.

High pressure rotary valve (HRV type)

1.Seal pressure may reach to 0.4 Mpa.

2.Side seal structure largely lowers the leakage.

3.As side seal adopts soft sealing material, it is free of abrasion even with friction. Excellent sealing performance prolongs the service life.

4.In order to lower the leakage of high pressure difference, there’s the exhaust pipe design on the body which can discharge the granules stably.

5.Powder uses HRF type and granule uses HRV type.

6.The HRV type’s material inlet is designed to be W shape to avoid material broken which is caused by material bite.

7.Supposing the bite rate is 100% when the casing inlet is perpendicular to rotor blades, it can be reduced to 50% if the rotor is in V shape; With W type casting inlet, it can be reduced to 1/3 if the rotor is in V shape.

8.In addition, W type could ensure wide opening area of material inlet, and reduce influence of air leakage.

9.The shaft seal adopts double-lip seal ring (material: PTFE of wear resistance), which brings good sealing performance and long service life.

Dust Collector

It is made by different materials (SS400, SUS304, SUS316) according to property of material, which also can be made by special material as special working condition of customer. Its intensity could fully support the internal and external pressure difference. According different materials to adopt suitable clothe filter or filtering hopper to be the carrier for ideal de-dusting performance. Its dimension can be customized, and it’s available to offer customization for filtering area of 0~500M2. The dust collector mainly conveys the separated dust powder pneumatically, recycles the gas in boiler flue and the dust in workshop.

Working temperature: -10°C~170°C

Applicable area: Common area, anti-explosion area.

Applicable work condition: Non-corrosion and corrosion dust area.

Application: All industries requiring de-dusting.

Special Reports

- Application of SCAD Used in 3D Printing

- “One-to-Two” Compact Dryer

- Dust Separators SDS-500

- “Large Flow” Water Heater STM-WFN

- Side Entry Robot

- Application of Valve Hot Runner

- My Shini Life

If you want to read other articles, back to2017 Quarter 2 Issue 31.