Special Reports

2020 Quarter 4 Issue 41

Auto Multi-component Proportional Mixing Technology

Plastic processing usually involves proportional mixing technology. In addition to manual or semi-mechanized proportional mixing of different materials by manpower, auto proportional mixing by equipment has been widely used throughout the industry.

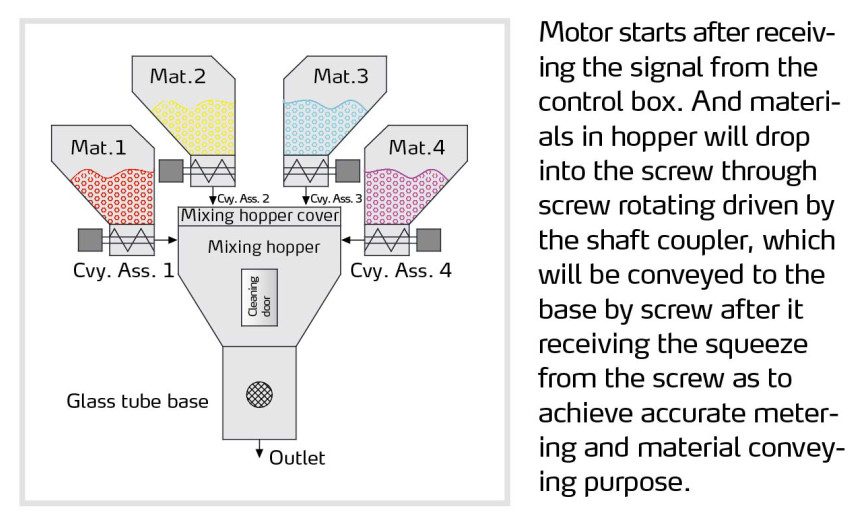

In the application of auto proportional mixing of plastic materials, in addition to the commonly used Volumetric Doser SCM and Gravimetric Blender SGB machines on the market, the new product of Shini Proportional Mixer SPM effectively fills the application gap between SCM and SGB, which integrates their advantages and applies to auto proportional mixing of multi-components in the plastic processing. After putting those materials into each hopper of the SPM, it only needs to input the required mix proportion to achieve efficient and straightforward mixing automatically and precisely. We provide four kinds of screws for the customer for actual demands on the market, and they are 12, 16, 30, 40mm respectively. The maximum production capacity of a single screw is up to 90kg/h. The machine can be transformed into three modes, i.e., four-material, three-material, and two-material proportional mixers to meet different process requirements.

Main Features:

1. Simultaneous metering and dosing make mixing unnecessary.

2. An efficient mix of materials, regardless of its density, size, or shape.

3. Modular assembly structure with convenient assembly and disassembly is easy for cleaning up and exchange.

4. The unit is unaffected by power failure and can resume work at once after the power is back.

5. Set a manual material cleaning valve for the simple material change.

6. Recipe of recordable is convenient for saving and retrieving.

7. DC brushless motor is free of maintenance.

8. Material blockage and overload alarm with auto-shutdown protection.

9. The optional low-level sensor provides early warning to empty material.

10. Equipped with a material test port that is easy for the customer to test the discharge capacity.