Special Reports

2021 Quarter 3 Issue 44

Shini Stunning Tech | Mould Temperature Controller

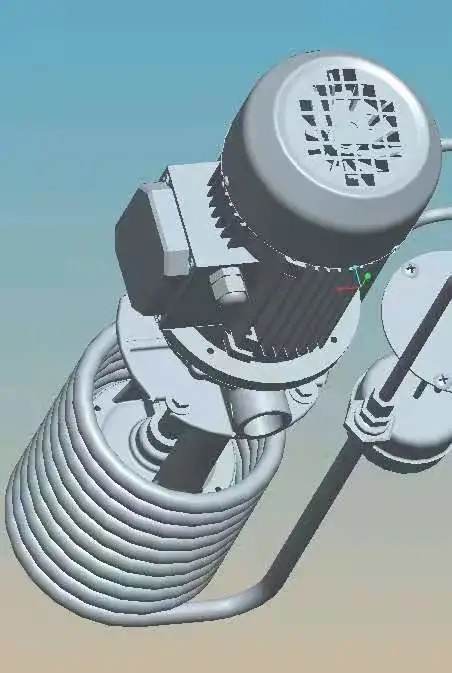

Compared with other single medium mould temperature controllers on the market, the new Shini Dual-purpose Water/Oil Heater STM-W/O can switch between water and heat transfer oil to meet more diversified production demands. Facing the development trend on the market, we can quickly adjust the production line with the machine to match different temperature control occasions. For machine replacement, we only need to operate outside the equipment to start the pump reverse emptying function to let the medium return to the container so that the mould can be easily replaced and put into production again.

In this way, customers can change the mould as their demands. What's more, it will automatically complete the conversion and adjustment within the upper-temperature control limit when switching between the controller's water and heat transfer oil mode to ensure reliable production.

Secondly• Smart Technology Customized Release of the Productivity

The intelligent, customized design brings unprecedented production reforms in addition to the enhanced core competitiveness of the enterprise. We adopt the 4.3 "integrated touch panel to replace the traditional button interface, giving the new product generation a modern look.

Regarding pipe heater power control, we choose the combined heating element with three independent heating pipe zones to work efficiently and independently. That realizes the power switching of the mould temperature controller between 3KW, 6kW, and 9kw, and saves your time and energy.

A stream of cold water should not stop the full-swing production! Compared with the last generation of the product, we have improved water replenishing settings and optimized previous single and rigid replenishing processes, which solved the issues as machine shutdown at low level or "replenishing strike" during water overflow and short circuit. The brand new mould temperature controller STM-907W/O has two stages of fluid levels. It can make up water automatically at the low fluid level and stop automatically when the liquid reaches the high level.

Besides, we have also modified and upgraded the EGO overheat protector accordingly. The last safe defense is no longer placed in the partition pipe inside the machine box. In order to sense the temperature change faster, it is integrated into the unit to bring in simple maintenance, and an efficient detection function is placed close to the machine box outside at the low-level position to narrow the monitoring error caused by liquid level change and temperature transfer reduction.

Besides, we have also modified and upgraded the EGO overheat protector accordingly. The last safe defense is no longer placed in the partition pipe inside the machine box. In order to sense the temperature change faster, it is integrated into the unit to bring in simple maintenance, and an efficient detection function is placed close to the machine box outside at the low-level position to narrow the monitoring error caused by liquid level change and temperature transfer reduction.

Thirdly•Strong PerformanceGive You Unexpected Cost effective

Most importantly, Shini new generation of mould temperature controllers adopts accurate and fast temperature controllers still.

The temperature range can reach 90 ℃ (for water) or 160 ℃ (for heat transfer oil), with control accuracy up to ± 0.5 ℃ / 0.9 ℉. Once it overheats, the spiral water-cooling pipe at the pump head starts to work, taking away the heat around the pump head immediately.

In addition to the core components, the Shini mould temperature controller can easily handle leakage or blockage. When the mould or pipe leaks and it's hard for us to take, we only need to activate the negative pressure operation mode. Even this never happens but would be potentially occurred; the machine can be water tight.With an optional flow meter, the flow sensor can sense the medium flow change, give an early warning, and notify the operator for troubleshooting instantly once the mold is blocked.

Moreover, it also can collocate with the medium temperature detection and pressure detection functions to make each data present in front of you.

Special Reports

If you want to read other articles, back to2021 Quarter 3 Issue 44.