Special Reports

2021 Quarter 3 Issue 44

Shini New Vitality is Just for High-Tech Feeding!

"A little body often harbors a great soul"! ----SGD-Micro

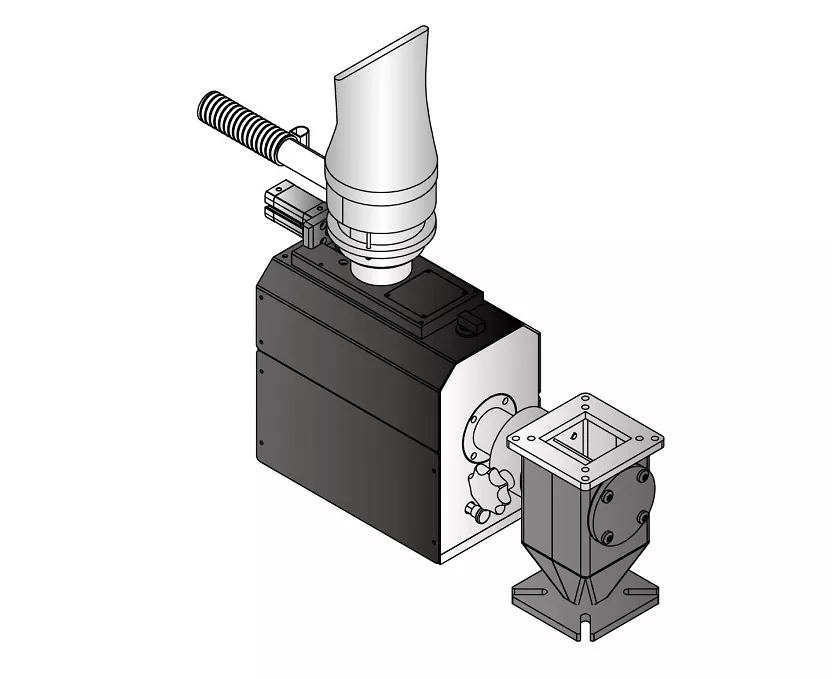

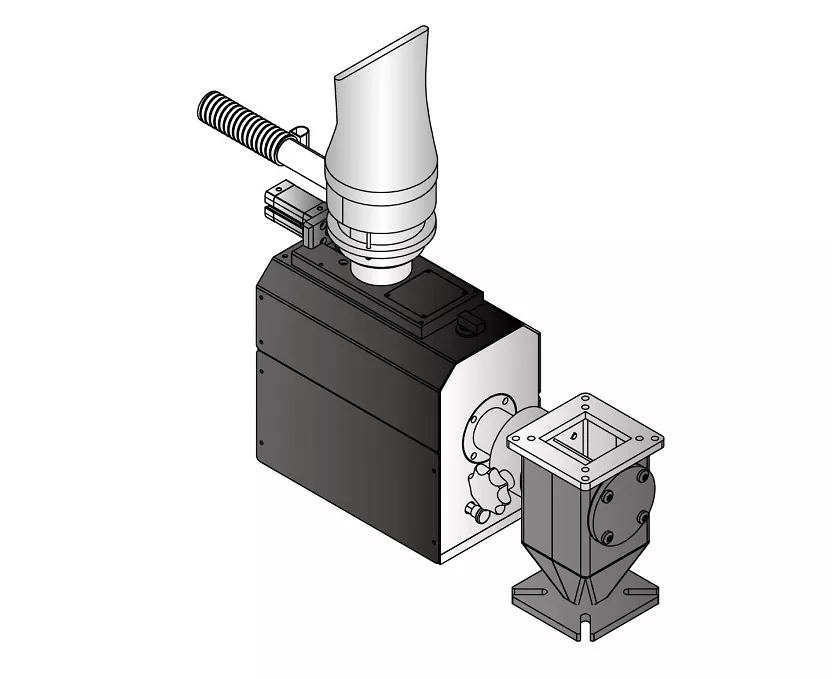

As a gravimetric feeder focused on precise feeding, SGD micro is different from other feeding products in appearance and internal structure. It abandons the traditional motor and screw design, making it unable to cope with bulky and heavy-duty feeding works. Still, it enables unique vibrating feeding that advances a new unit to enter another new demand.

This unique feeding mode helps it apply to feeding medical, optical, and miniature precision products. The metering accuracy can reach up to 0.01g, which meets the feeding requirements of various precision productions.

Keeping self-awaking to make the error close to 0

As feeding needs to control the metering and maintain a stable and uniform feeding speed, it requires the feeding to correct the error caused by objective conditions and know how much material it has fed in a certain period? Did it feed more or less? Fast or slow? How to feed the next?

SGD-Micro adopts the gravimetric structure to compare with the preset values repeatedly and adjust them dynamically by continuously weighing the materials in the hopper to cope with this series of issues.

# The Gravimetric Structure #

The system will automatically change the vibrator strength of the machine, thus finally making a stable feeding process to prevent excessive feeding or material shortage.

Besides, the electrostatic impeder is optional inside the machine that can ionize air molecules. When the ionized air is injected into the interior, it can neutralize the static electricity carried by the masterbatch or additive to prevent them from repelling and attracting each other, resulting in material bonding and affecting the feeding effect.

Simple Solution reflected in all aspects

As a prestigious product of Shini, we have dedicated ourselves to the design concept besides focusing on the development to make each operation simpler and production more convenient. The word "Shini" engraved on the SGD-Micro surface is not only reflected in its operational performance.

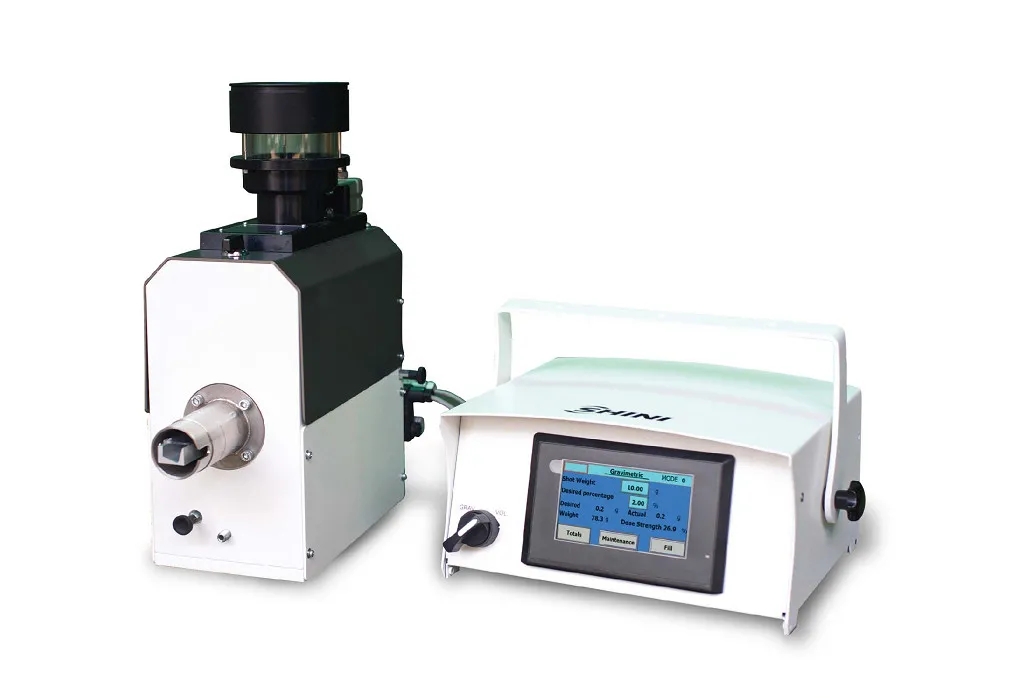

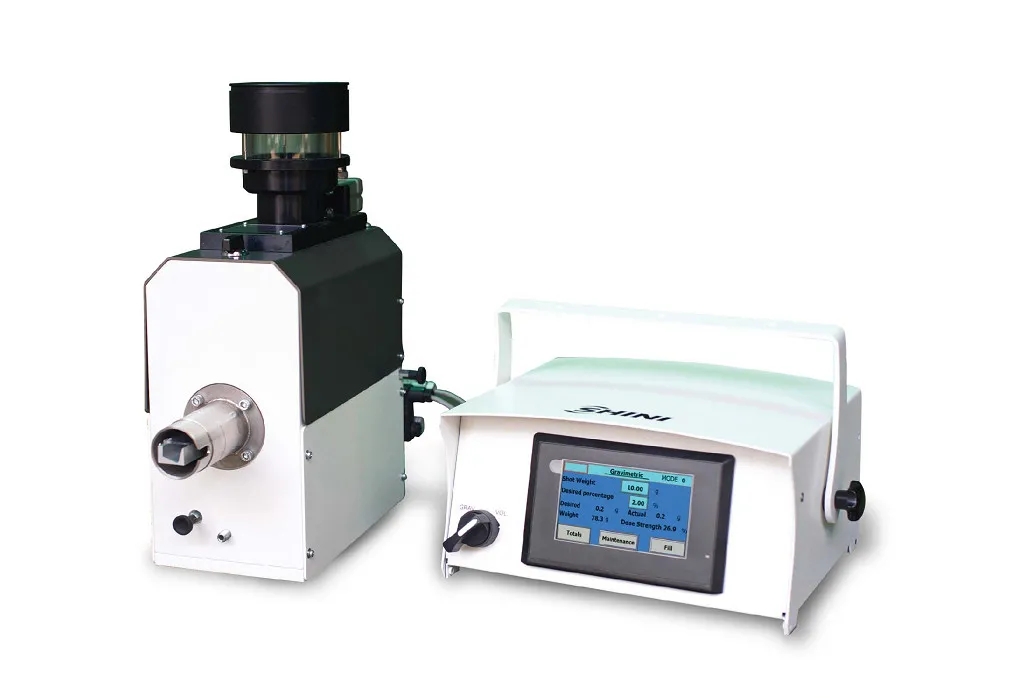

It adopts a touch interactive screen to display various essential system indicators and data. The operator can set multiple Feeder parameters intuitively through different colors, icons, and various symbol arrows.

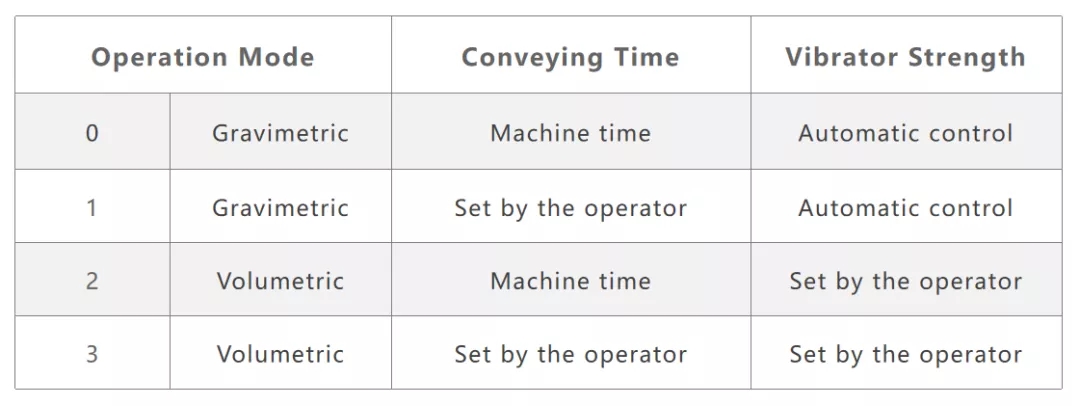

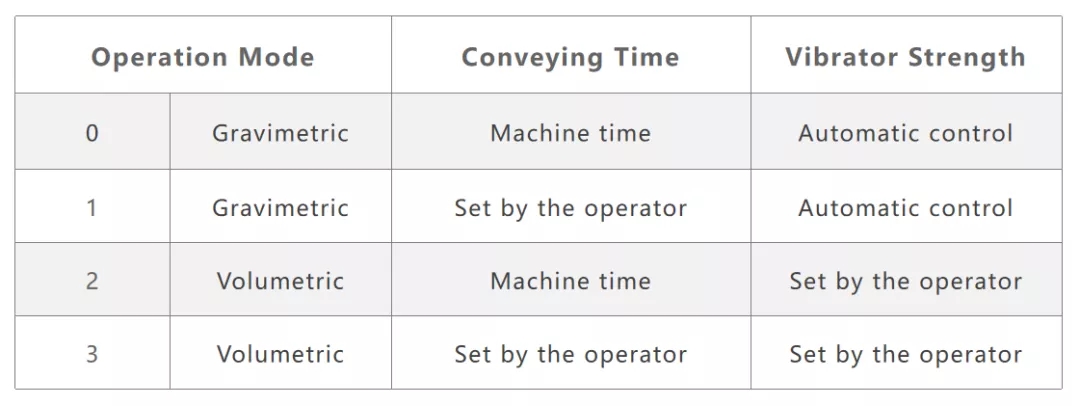

We added a change-over switch on its front panel to realize the switching between SGD-Micro's gravimetric mode and volumetric mode via one button press by the users. Moreover, it also set four operation modes to meet the actual demands of different applications.

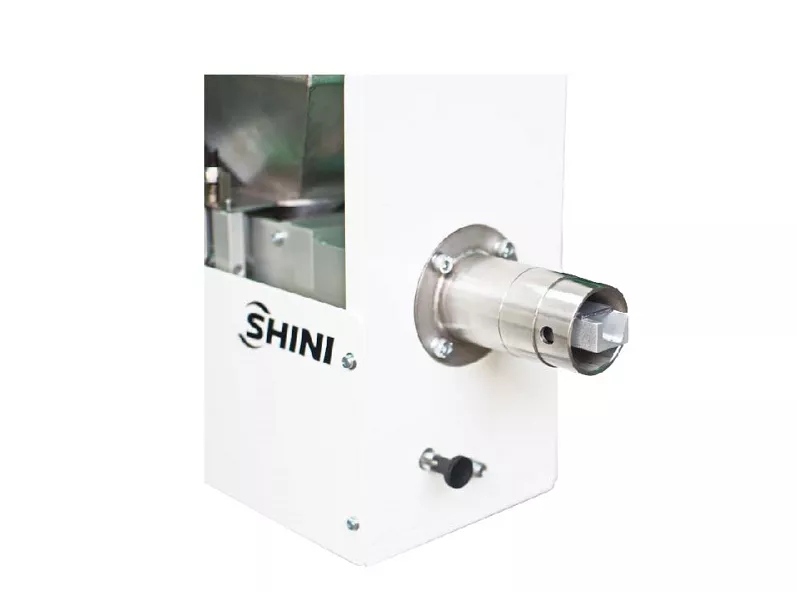

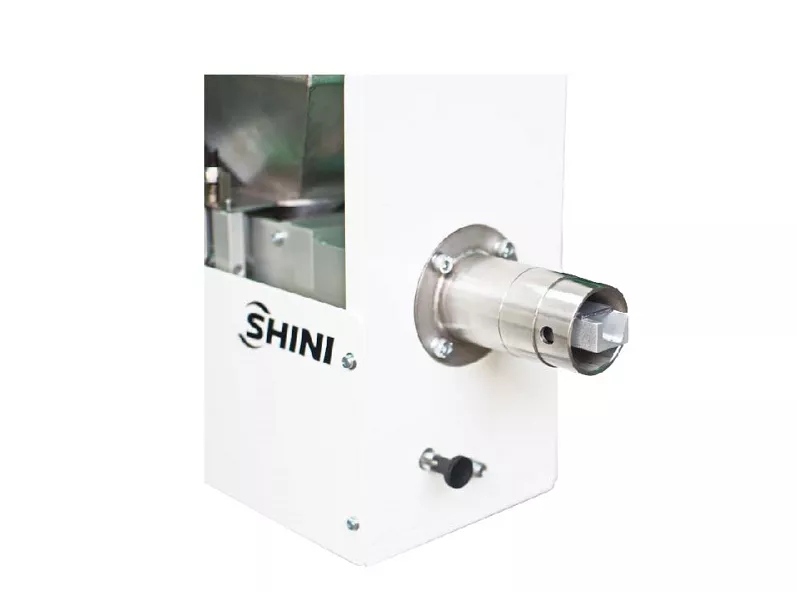

In addition to the operation design, we also considered material replacement and cleaning. When users use the SGD-Micro to replace the masterbatch frequently and make it applicable to producing different colors or models of products, to make the customers switch the materials faster, we have optimized and simplified the product structure to achieve rapid disassembly and assembly.

As a gravimetric feeder focused on precise feeding, SGD micro is different from other feeding products in appearance and internal structure. It abandons the traditional motor and screw design, making it unable to cope with bulky and heavy-duty feeding works. Still, it enables unique vibrating feeding that advances a new unit to enter another new demand.

This unique feeding mode helps it apply to feeding medical, optical, and miniature precision products. The metering accuracy can reach up to 0.01g, which meets the feeding requirements of various precision productions.

Keeping self-awaking to make the error close to 0

As feeding needs to control the metering and maintain a stable and uniform feeding speed, it requires the feeding to correct the error caused by objective conditions and know how much material it has fed in a certain period? Did it feed more or less? Fast or slow? How to feed the next?

SGD-Micro adopts the gravimetric structure to compare with the preset values repeatedly and adjust them dynamically by continuously weighing the materials in the hopper to cope with this series of issues.

# The Gravimetric Structure #

The system will automatically change the vibrator strength of the machine, thus finally making a stable feeding process to prevent excessive feeding or material shortage.

Besides, the electrostatic impeder is optional inside the machine that can ionize air molecules. When the ionized air is injected into the interior, it can neutralize the static electricity carried by the masterbatch or additive to prevent them from repelling and attracting each other, resulting in material bonding and affecting the feeding effect.

Simple Solution reflected in all aspects

As a prestigious product of Shini, we have dedicated ourselves to the design concept besides focusing on the development to make each operation simpler and production more convenient. The word "Shini" engraved on the SGD-Micro surface is not only reflected in its operational performance.

It adopts a touch interactive screen to display various essential system indicators and data. The operator can set multiple Feeder parameters intuitively through different colors, icons, and various symbol arrows.

We added a change-over switch on its front panel to realize the switching between SGD-Micro's gravimetric mode and volumetric mode via one button press by the users. Moreover, it also set four operation modes to meet the actual demands of different applications.

In addition to the operation design, we also considered material replacement and cleaning. When users use the SGD-Micro to replace the masterbatch frequently and make it applicable to producing different colors or models of products, to make the customers switch the materials faster, we have optimized and simplified the product structure to achieve rapid disassembly and assembly.

Special Reports

If you want to read other articles, back to2021 Quarter 3 Issue 44.