Special Reports

2022 Quarter 3 Issue 48

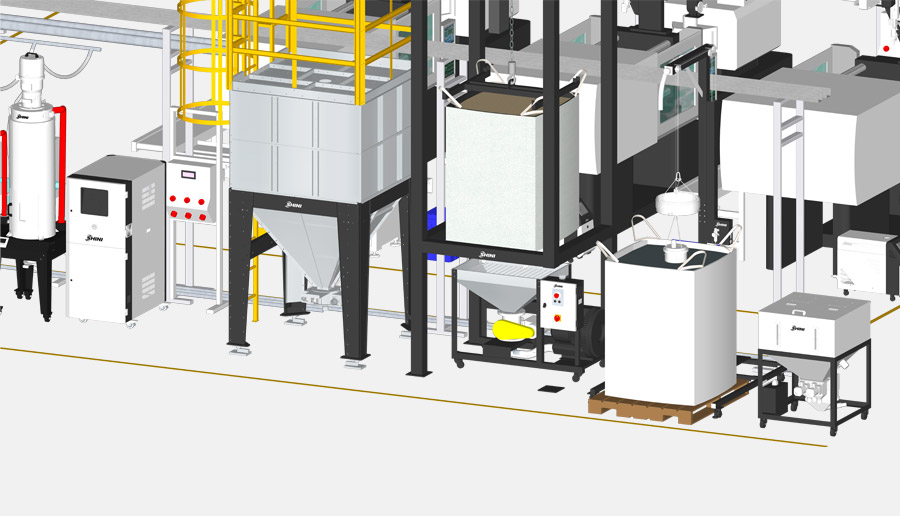

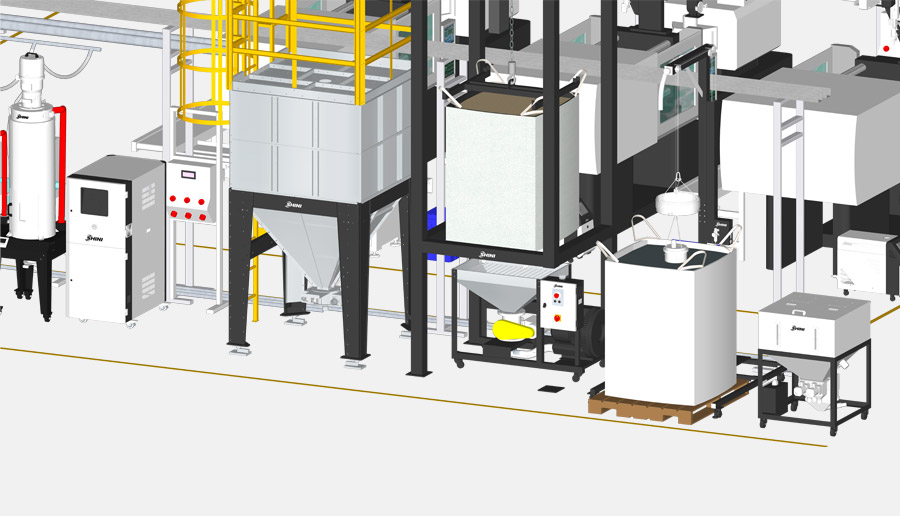

Large Bulk Conveying Made Simple, Pressure Conveying.

China’s plastic production industry has been developing rapidly in recent years. With the continuous growth of injection moulding machines and international markets, the use of plastic materials brings about greater needs and more business opportunities for manufacturers of injection moulding machines and plastic material handling equipment. The production of plastic products, conveying an extensive number of plastics material smoothly and quickly without errors, has been one of the challenging issues developed and researched by the manufacturers of plastic material handling equipment of all time. Under such circumstances, positive pressure conveying SRPC emerges as the times require.

Shini Positive Pressure Conveying SRPC

Compared with a vacuum, positive pressure conveying requires fewer parts and accessories. The system without the need for the vacuum hopper receiver and the vacuum breaking time taken prior to the material discharge. It can move materials continuously over a long distance in large quantities. The unit is light, convenient, easy, and safe to use without contamination.Shini positive pressure conveying is also equipped with a stainless steel hopper for independent manual feeding, which adds to its applications. Besides, the unit has no limitation to the height and space in the workshop, and the location can be adjusted as demanded. The conveying option is open and can be used per operation or working needs.

Features

• The unit uses a high-pressure or optional roots blower to convey extensive capacity over a long distance.

• The universal castor wheel allows free movement of the unit without space limitation.

• The unit includes a stainless steel hopper. Convenient for manual or jumbo bag feeding.

• A high-precision rotary valve is made of SUS304 and has a SEW gear motor for highly efficient conveying material.

• The material contacted surface is made of SUS201, which ensures no contamination.

• The frequency converter is optional to control the speed of the rotary valve and the throughput.

• An optional cyclone filter is available, and it can be mounted on the silo at the end of conveying line. It will exhaust the air, filter the dust within, and prevent contamination.

Case Sharing

Application of Shini Positive Pressure Conveying SRPC

Shini Positive Pressure Conveying SRPC

Compared with a vacuum, positive pressure conveying requires fewer parts and accessories. The system without the need for the vacuum hopper receiver and the vacuum breaking time taken prior to the material discharge. It can move materials continuously over a long distance in large quantities. The unit is light, convenient, easy, and safe to use without contamination.Shini positive pressure conveying is also equipped with a stainless steel hopper for independent manual feeding, which adds to its applications. Besides, the unit has no limitation to the height and space in the workshop, and the location can be adjusted as demanded. The conveying option is open and can be used per operation or working needs.

Features

• The unit uses a high-pressure or optional roots blower to convey extensive capacity over a long distance.

• The universal castor wheel allows free movement of the unit without space limitation.

• The unit includes a stainless steel hopper. Convenient for manual or jumbo bag feeding.

• A high-precision rotary valve is made of SUS304 and has a SEW gear motor for highly efficient conveying material.

• The material contacted surface is made of SUS201, which ensures no contamination.

• The frequency converter is optional to control the speed of the rotary valve and the throughput.

• An optional cyclone filter is available, and it can be mounted on the silo at the end of conveying line. It will exhaust the air, filter the dust within, and prevent contamination.

Case Sharing

Application of Shini Positive Pressure Conveying SRPC

Special Reports

- A Step of Mould Flow Detection Plays A Decisive Role in Production

- Shini @ VietnamPlas 2022

- ShiniEurope Quarterly 2022 No.2

- ShiniEurope Quarterly 2022 No.3

If you want to read other articles, back to2022 Quarter 3 Issue 48.