Special Reports

2026 Quarter 1 Issue 54

The Significance of Monitoring the Mould’s Water Flow Rate

The mould’s water flow rate is critical for injection moulding, die-casting and other manufacturing processes that rely on precise temperature control. The cooling water (or heating medium) flowing through the mould is the key factor to control the mould temperature. Correct water flow can ensure mould maintains a consistent temperature throughout the production cycle, accelerating the product cooling rate and shortening the moulding cycle, thus improving productivity. If the water flow is insufficient, the mould may be unevenly overheated or cooled, resulting in defects in the product, such as twist, poor shrinkage and surface, etc.

Therefore, continuous monitoring of the mould water flow rate ensures smooth manufacturing and improves product quality and productivity. This determines the product quality and affects the stability and cost-effectiveness of the entire production system. Monitoring the flow can help to find and solve the problems that may lead to production interruption, such as scale deposition, pipeline corrosion or leakage, avoiding unnecessary downtime. It can also detect blockage and other issues in time, prevent the cooling channel inside the mould from being damaged due to long-term blockage, and prolong the mould service life. For batch-manufactured parts, maintaining constant cooling conditions is the premise to ensure each product has the same quality and characteristics and that each batch of products can meet the expected standard.

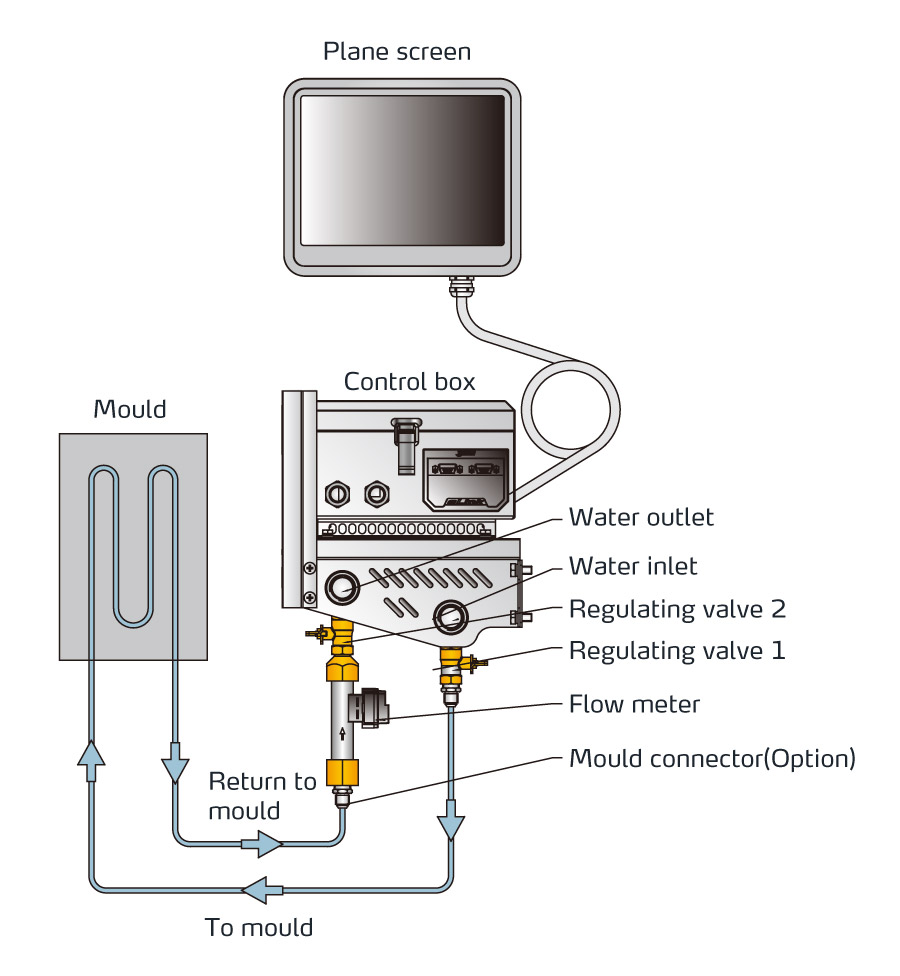

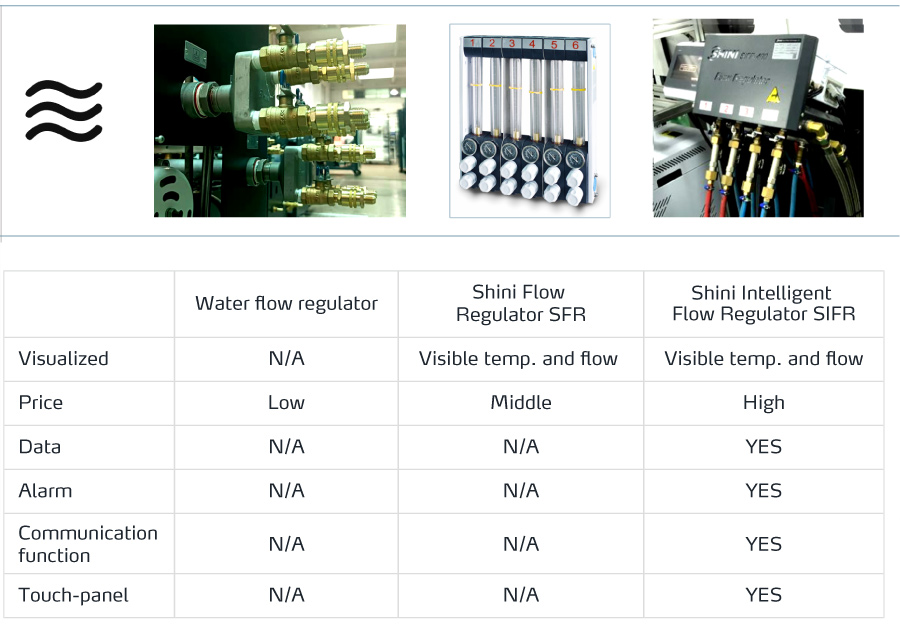

As an essential technology in modern industrial automation, the Shini Intelligent Flow Regulator SIFR is reliable in improving productivity, saving energy, and guaranteeing product quality. Its working principle is to measure the fluid present flow through the flow meter mounted in the pipeline and adjust the valve opening manually or automatically according to the preset value to achieve precise fluid flow control. The main features are as follows:

1. Measure the flow and temperature simultaneously.

2. Maximum working temperature can reach 120℃.

3. Open interface without any communication barriers.

4. Support manual or auto flow regulation.

5. Friendly touch interface.

6. Synchronous display of total flow and partial flow.

7. Alarm threshold setting of each loop and support recipe functions.

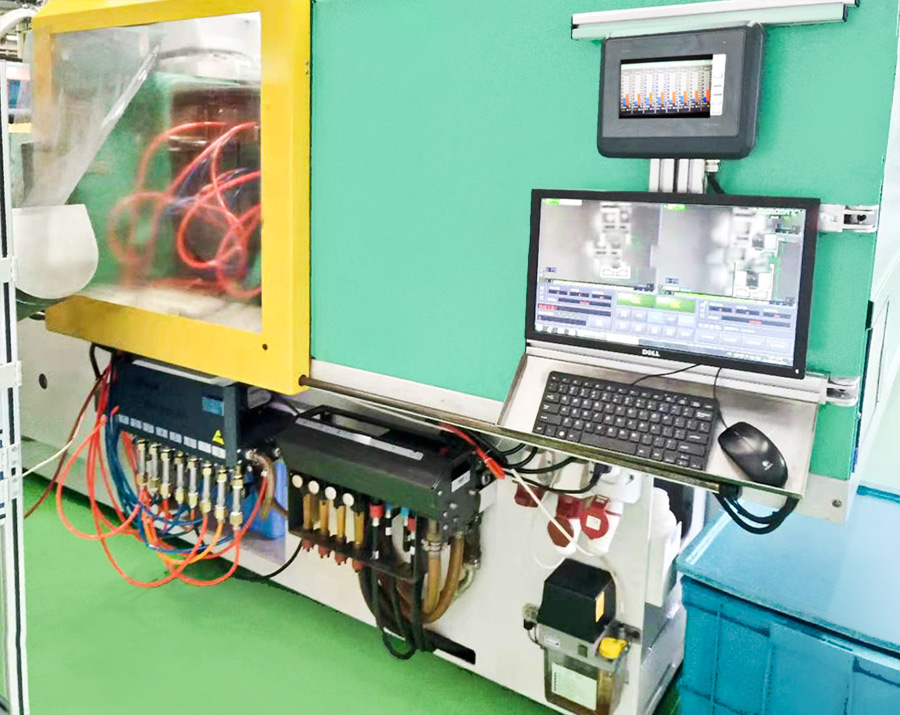

1. Machine Mounted Type(Standard)

Shini Intelligent Flow Regulator SIFR can help manufacturing enterprises realize precise control of the mould water flow rate and significantly improve production efficiency, save energy and ensure product quality. By continuously monitoring and optimizing the water flow rate, enterprises can reduce production interruption risks, extend the mould service life, and ensure that each batch of products can meet the expected quality standard. This undoubtedly is an indispensable technological innovation for manufacturers pursuing high productivity and high-quality products.

Special Reports

- The Open Day Concluded Perfectly!

- 15th Anniversary Celebration of Shini India

- Shini Made a Splash at K 2025

- K2025 Wrapped Up Successfully

- Shini Europe 25th Anniversary!

If you want to read other articles, back to2026 Quarter 1 Issue 54.