Experience Sharing

2013 Quarter 4 Issue 17

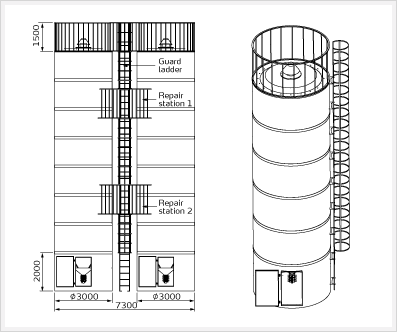

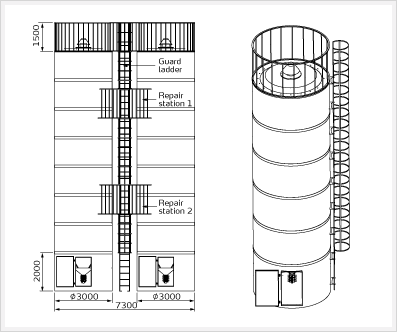

Storage Silo

Just like its name, storage silo is a container for storing loose solid material, which is different from containers for storing gas and liquid. The loose solid material will have pressure against the walls of solid silo which are below material surface as well as frictional force against wall surfaces of solid silo when the material is flowing. Therefore, it’s necessary to consider storage silo’s specificity as well as its common character when designing.

Shini possesses a complete quality control system which ensures manufacture of qualified storage silo. With a professional designer of silo, Shini has strong technical support. For designing, material flow is usually divided into overall flow pattern and central flow pattern. The overall flow pattern is the most ideal one since it complies with the first-in-first-out principle and makes the silo shell stressed more evenly. Meanwhile, Shini owns professional production team which masters various welding technologies to produce silos of good quality.

In actual production and sales, we usually encounter some problems as follows: Losing some clients, since clients doubt our price of silo and think our price is a little expensive. Actually, as a device of special application and structure, silos are of various kinds. Their structures and manufacturing technologies are also largely different. When choosing material, it’s necessary to consider the working condition of silos, the welding performance of material, manufacturing techniques and economic rationality, etc. Silos made of different material qualities will be greatly different in service life period and price. It should be noticed that the welding material as well as the welding technology varies along with the steel material quality during the welding process of sheet material. All surfaces of welded joints contact with material should be polished to be level with the base metal. To make sure the silo is well sealed, the fillet weld where the connection pipe connects with the silo shell should be tested after the dimensions and appearances of welded joints have passed the test. The above procedures are just one part of manufacturing silos. The manufacturing process is not just about the simple material joints, but full of severe standards and specifications.

Storage silo is playing a more and more important role in raw material storage and feeding & conveying system of positive pressure.

Shini possesses a complete quality control system which ensures manufacture of qualified storage silo. With a professional designer of silo, Shini has strong technical support. For designing, material flow is usually divided into overall flow pattern and central flow pattern. The overall flow pattern is the most ideal one since it complies with the first-in-first-out principle and makes the silo shell stressed more evenly. Meanwhile, Shini owns professional production team which masters various welding technologies to produce silos of good quality.

In actual production and sales, we usually encounter some problems as follows: Losing some clients, since clients doubt our price of silo and think our price is a little expensive. Actually, as a device of special application and structure, silos are of various kinds. Their structures and manufacturing technologies are also largely different. When choosing material, it’s necessary to consider the working condition of silos, the welding performance of material, manufacturing techniques and economic rationality, etc. Silos made of different material qualities will be greatly different in service life period and price. It should be noticed that the welding material as well as the welding technology varies along with the steel material quality during the welding process of sheet material. All surfaces of welded joints contact with material should be polished to be level with the base metal. To make sure the silo is well sealed, the fillet weld where the connection pipe connects with the silo shell should be tested after the dimensions and appearances of welded joints have passed the test. The above procedures are just one part of manufacturing silos. The manufacturing process is not just about the simple material joints, but full of severe standards and specifications.

Storage silo is playing a more and more important role in raw material storage and feeding & conveying system of positive pressure.

Experience Sharing

- The Case of Large-scale System of Dehumidifying and Drying Combined with Central Feeding System

- The Successful Application of SS-S Robots in Toys Industry

If you want to read other articles, back to2013 Quarter 4 Issue 17.