Special Reports

2014 Quarter 4 Issue 21

Shini Gravimetric Blender SGB Flakes Solution

For recent twenty years, demands of thermoforming container and package plastic film are growing day by day with the development of plastics industry. It is estimated that the demands of plastic films in global market will reach 71 million tons in 2020. Under the major premises of productivity increase, waste material reduction, quality improvement and cost reduction, all of us are paying more and more attention to the leftover material recycling. The weighing of flakes has always been a tough question within industry. Hereby, let us refer to the features of flakes and the solutions.

Flakes are mainly recycled from leftover material of bottles or thin plates through crushing process, which feature lightweight and thinness. The thickness ranges 0.5~1.5mm, dimension 8~20mm, bulk density 0.2~0.4kg/L, with irregular shape and extremely poor liquidity. Weighing difficulty of the material is lightweight, thinness and irregular shape; therefore, the standard discharge port can’t meet the discharging requirement at all. Poor liquidity makes flakes easy bridging and blockage. It also results in machine alarm and weighing error. Slow free falling and unstable flow velocity lead to metering error.

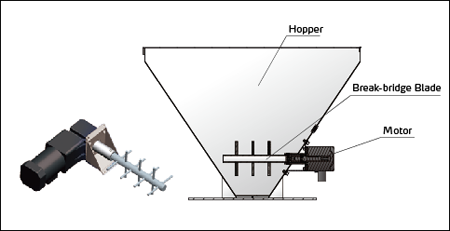

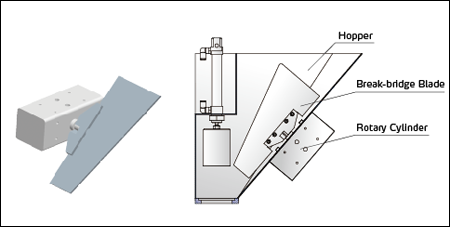

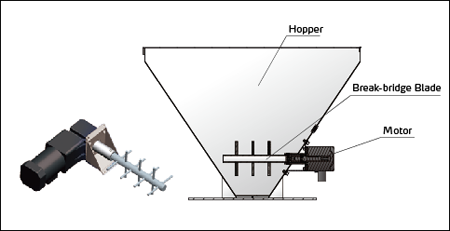

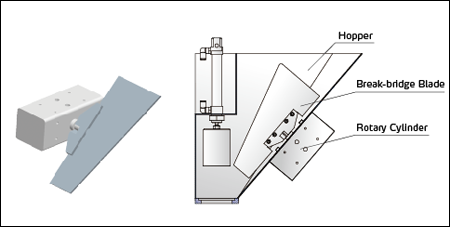

For above points, there are two main solutions within the field: one is to enlarge the diameter of discharge port for flakes easy falling; the other is to let external force to break-bridge, for example, to adopt mixing motor break-bridge device or rotary cylinder break-bridge device.

Enlarge the diameter of discharge port to the maximum that material could fall smoothly. Enlarge it to maximum diameter within the limitation to make the largest discharging area. But this method is subject to the area affected by hopper bottom plate. It works on small-flakes-discharging. When the dimension exceeds 12mm, this method won’t work well, and the problem of material bridging will show up.

Motor mixing or rotary cylinder anti-bridge device utilizes gear motor or rotary cylinder to drive the anti-bridge blade to make external force to the flakes. It pushes the flakes to discharge port direction, and makes break-bridge smoothly. With external force, it could ensure the flakes will fall into the weighing pan. But the material flow is unstable which brings about large metering fluctuation and costs a lot.

Shini is going to take constant experiments to improve SGB’s adaptability towards flakes as to satisfy customized gravimetric requirement of different forms of materials.

Flakes are mainly recycled from leftover material of bottles or thin plates through crushing process, which feature lightweight and thinness. The thickness ranges 0.5~1.5mm, dimension 8~20mm, bulk density 0.2~0.4kg/L, with irregular shape and extremely poor liquidity. Weighing difficulty of the material is lightweight, thinness and irregular shape; therefore, the standard discharge port can’t meet the discharging requirement at all. Poor liquidity makes flakes easy bridging and blockage. It also results in machine alarm and weighing error. Slow free falling and unstable flow velocity lead to metering error.

For above points, there are two main solutions within the field: one is to enlarge the diameter of discharge port for flakes easy falling; the other is to let external force to break-bridge, for example, to adopt mixing motor break-bridge device or rotary cylinder break-bridge device.

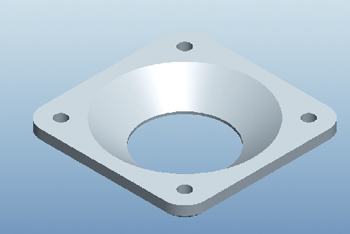

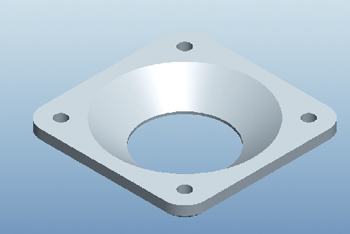

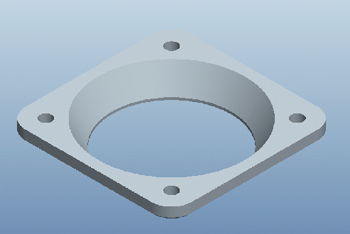

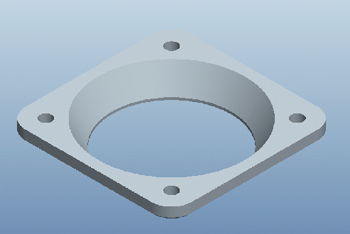

Standard Metering Valve Discharge Port

Add-up Metering Valve Discharge Port

Add-up Metering Valve Discharge Port

Enlarge the diameter of discharge port to the maximum that material could fall smoothly. Enlarge it to maximum diameter within the limitation to make the largest discharging area. But this method is subject to the area affected by hopper bottom plate. It works on small-flakes-discharging. When the dimension exceeds 12mm, this method won’t work well, and the problem of material bridging will show up.

Motor mixing or rotary cylinder anti-bridge device utilizes gear motor or rotary cylinder to drive the anti-bridge blade to make external force to the flakes. It pushes the flakes to discharge port direction, and makes break-bridge smoothly. With external force, it could ensure the flakes will fall into the weighing pan. But the material flow is unstable which brings about large metering fluctuation and costs a lot.

For above points, Shini has recently developed a special metering valve and discharge port with new design(patent under applying). The discharge port changes from round to square. It not only enlarges the discharge areas but also makes material hard for bridging. By this way, the effect of bridging prevention, stable flow and low cost are reached. It is simple and economical.

Shini is going to take constant experiments to improve SGB’s adaptability towards flakes as to satisfy customized gravimetric requirement of different forms of materials.

Special Reports

- Gravimetric Blender SGB Data-collection Software

- Shini Granulator Energy-saving Motor Update

- Application of SLWF in Extrusion Molding Machine

- Oil Filter Applied in Plastics Drying and Dehumidifying

- Shini Launches Energy-saving Hopper Dryer SHD-EH

- Modular Drying and Dehumidifying

If you want to read other articles, back to2014 Quarter 4 Issue 21.