Special Reports

2014 Quarter 4 Issue 21

Gravimetric Blender SGB Data-collection Software

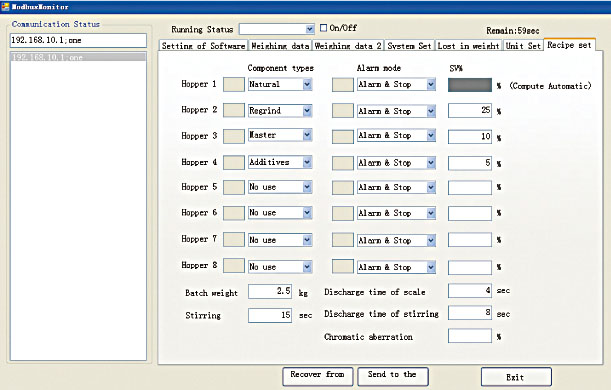

Shini Gravimetric Blender SGB series is applicable to plastics injection, extrusion as well as blow molding etc. which in process requires applications of different ingredients according to weight proportion. The controller adopts B&R PLC controlling system and the advanced ingredient recipes. Before every start-up, it can perform self-calibration to ensure precise accuracy.

This series of products adopt high-precise load cell to control every lot of recipe with accuracy in ±0.1~0.3%. The products consist of 8 models whose maximum handling capacity is 3000kg/hr.

Features

•Auto-repetition calibration function, after every weighing it can process self-calibration program to ensure optimal recipe accuracy.

•It has auto-feeding control function.

•auto-compensation function of recycling materials can according to the discharging quantity to perform auto-calculation aberration compensation.

•Ethernet communication realizes central monitoring function and data collection with the molding machines.

•Analog signal of current output function (0~10V) is optional, which convenient for extruder’s screw rpm self-adjustment.

Data-collection software function

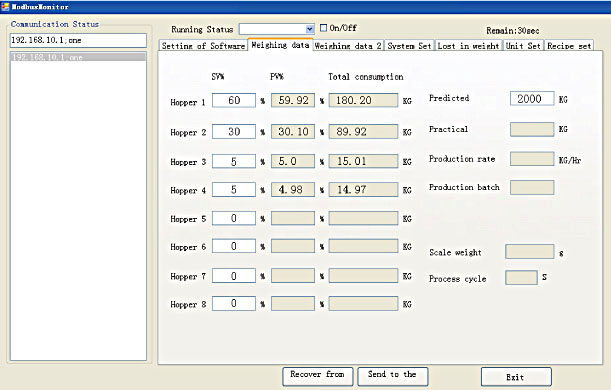

•The actual additive proportion, throughput, each material accumulated dosage and material flow rate, recycling material, master batch, additives can be read as below:

•Every lot of material, recycling material, master batch and additives can be in real-time monitored.

•SGB panel and blender related parameter can be edited simultaneously, current recipe also can be edited.

•Blender operation status and start/stop control display.

Special Reports

- Shini Gravimetric Blender SGB Flakes Solution

- Shini Granulator Energy-saving Motor Update

- Application of SLWF in Extrusion Molding Machine

- Oil Filter Applied in Plastics Drying and Dehumidifying

- Shini Launches Energy-saving Hopper Dryer SHD-EH

- Modular Drying and Dehumidifying

If you want to read other articles, back to2014 Quarter 4 Issue 21.