Experience Sharing

2014 Quarter 4 Issue 21

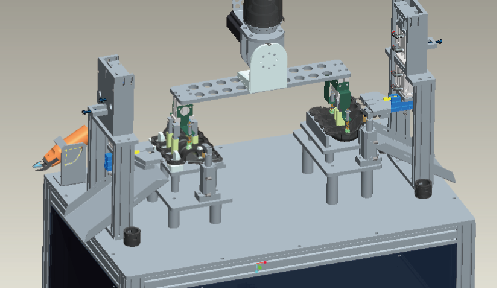

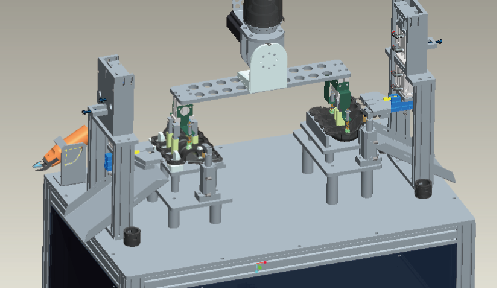

Smart Five Axes Servo Driven Robot successfully applied in automobile industry

As the living standard improves, the requirement of house cars increase accordingly .Specially in China, the large population and people’s consumption power are continuously improving. It is a huge opportunity for those auto accessories manufacturers, and it also brings challenges to them. Increasing car demand and requirement for higher quality and better production efficiency require higher automation. Therefore, the selection of suitable automation equipment is vitally important.

Auto Parts company in Shenyang with 20,000 square meters occupancy is a manufacturer of plastic parts using forging and machining processes. It is a certified accessory part provider for more than 10 auto makers. Its main plastics products include plastic inlet manifold, plastic cover and so on.

The company bought 5 sets of robots, ST3-1800-2400LT-BC, from Shini and used them for product pickup and automatic separation of spure in 2013.The result is very satisfactory and the monthly production efficiency increase 35% compare to the same period.

The ST3 series robot is designed for rapid and precise removal of products from injection molding machine, and place them at desired locations. Standard and telescopic arm are selectable to cooperate with 2-plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine from 850~3600T clamp force. The end of arm tooling with optional BC servo axis can satisfy the most complicated arranging and stacking. Flexible multi -dimensional movement enables complicated product/sprue picking and optimal moving path, which allow further processing of the picked product.

Shini Robot engineer also shares the subsequent commonly used processing methods for removing sprue:

1. Cutting: pneumatic or electric cutter to cut off the sprue.

2. Punching: base on the shape and position of the product, using pneumatic or hydraulic punch cutter to cut off the sprue.

3. Bending: use the material characteristics of the product and simulate manual bending method to bend away the sprue.

Above sprue removal methods can be chosen according to product shape and characteristics.

Auto Parts company in Shenyang with 20,000 square meters occupancy is a manufacturer of plastic parts using forging and machining processes. It is a certified accessory part provider for more than 10 auto makers. Its main plastics products include plastic inlet manifold, plastic cover and so on.

The company bought 5 sets of robots, ST3-1800-2400LT-BC, from Shini and used them for product pickup and automatic separation of spure in 2013.The result is very satisfactory and the monthly production efficiency increase 35% compare to the same period.

The ST3 series robot is designed for rapid and precise removal of products from injection molding machine, and place them at desired locations. Standard and telescopic arm are selectable to cooperate with 2-plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine from 850~3600T clamp force. The end of arm tooling with optional BC servo axis can satisfy the most complicated arranging and stacking. Flexible multi -dimensional movement enables complicated product/sprue picking and optimal moving path, which allow further processing of the picked product.

Shini Robot engineer also shares the subsequent commonly used processing methods for removing sprue:

1. Cutting: pneumatic or electric cutter to cut off the sprue.

2. Punching: base on the shape and position of the product, using pneumatic or hydraulic punch cutter to cut off the sprue.

3. Bending: use the material characteristics of the product and simulate manual bending method to bend away the sprue.

Above sprue removal methods can be chosen according to product shape and characteristics.

Experience Sharing

- Medical Equipment Company Material Handling System

- Application of Shini Central Conveying System in Blowing Molding Equipments

If you want to read other articles, back to2014 Quarter 4 Issue 21.