Experience Sharing

2015 Quarter 4 Issue 25

Application of Shini sLink Protocol Solution in Injection Molding System

A hot-runner company in Shenzhen is specialized in providing hot-runner system and mould manufacturing services. In a bid to achieve the real-time monitor of the parameters from each auxiliary machine during the demonstration as well as to improve production efficiency during injection molding, the company introduced sLink Protocol Solution from Shini. Following is the integrated control plan applied in the injection molding system.

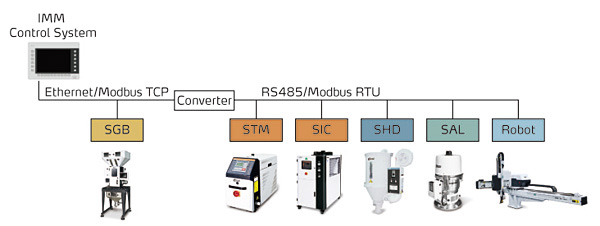

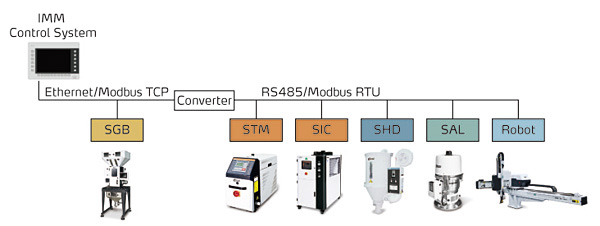

Hardware: the host machine adopts MILACRON IMM (B&R controller), auxiliary equipment employs each set of Shini SGB, STM, SIC, SHD, SAL and ST3 which equipped with the communication ports respectively. Through network interface, the IMM connects with these six units separately. As there are two different communication ports, Ethernet and RS485, existed in this integrated control system, the converter should be used at the port for interconversion.

Software: By the cooperative development with IMM manufacturers, it added the communication driver and monitor page to Shini auxiliary equipment based on original control program of IMM. That means Shini sLink Protocol Solution has been integrated into the control system of the IMM.

Via standard communication ports, the injection molding control system combines the monitor function of total auxiliary equipment to the control panel of the IMM, which achieves the centralized monitoring of the IMM and the auxiliary equipment. Different with the traditional remote control that only has some simple functions as well as temperature control or the start/stop of machine, the integrated control system is available to process date gathering and operation settings for all the parameters from equipment‘s controller. It helps the auxiliary equipment to fulfill the whole control functions with remote control. Compared with the separate and disperse control method of traditional IMM and auxiliary equipment, the injection molding control system that assembled with Shini sLink Protocol Solution makes the entire injection molding process more efficient and intelligent, finally reduces the costs and human labor.

Hardware: the host machine adopts MILACRON IMM (B&R controller), auxiliary equipment employs each set of Shini SGB, STM, SIC, SHD, SAL and ST3 which equipped with the communication ports respectively. Through network interface, the IMM connects with these six units separately. As there are two different communication ports, Ethernet and RS485, existed in this integrated control system, the converter should be used at the port for interconversion.

Via standard communication ports, the injection molding control system combines the monitor function of total auxiliary equipment to the control panel of the IMM, which achieves the centralized monitoring of the IMM and the auxiliary equipment. Different with the traditional remote control that only has some simple functions as well as temperature control or the start/stop of machine, the integrated control system is available to process date gathering and operation settings for all the parameters from equipment‘s controller. It helps the auxiliary equipment to fulfill the whole control functions with remote control. Compared with the separate and disperse control method of traditional IMM and auxiliary equipment, the injection molding control system that assembled with Shini sLink Protocol Solution makes the entire injection molding process more efficient and intelligent, finally reduces the costs and human labor.

Experience Sharing

- Central Conveying Applied in Home Appliance Field

- Robot for thin-wall product in Food packaging features

- Application of Shini Central Conveying System

- Shini Gravimetric Blender SGB Successfully Applied in Artificial Turf Industry

If you want to read other articles, back to2015 Quarter 4 Issue 25.