Experience Sharing

Shini Robots Used in North America

Recently, the issues of Smart Manufacture, Robot Replace Human, Industry4.0 have been raised by Web-based media.Manufacturing automation technology is widely used in our daily production. In order to improve production efficiency and reduce labor costs, automation technology has been adopted by manufacturing enterprises and become the global trend in manufacturing industry. Since automation technology is getting more and more mature, the clients were no longer satisfied by the simple automated equipment, they demand an upgraded smart system to integrate the data flow and make whole factory to be automated.

In order to satisfy our clients’ demands for plastics auxiliary equipment, Shini insists on one-stop shopping principle and global marketing strategy to help our clients to shorten their procurement time and maximize the profits. Our automation products are approved by CE certification and recognized by the international market.

This May, One company inUSA,

has purchased 15 sets of ST3 robots for their new expansion inMexico. The company

occupies 150,000 sq. feet, mainly produces plastics for home appliances. As we all know, the

basic wage of North America is increasing year by year, besides the enterprise needs to undertake

the costs

for employees’

benefits, insurances and new employees’ recruiting

and training, which can

be saved by using robots to replace human labors. One Shini ST3 robot could replace one employee; it works precisely and consistently for 24 hours a day, 7 days a week, providing

high level of reliable

performance.

The client chooses our ST3 series robot that is designed to remove products

from injection molding machine. Its three axes are all driven by servo motor

which can run precisely. Clients can choose the standard arm and telescopic arm to collocate with 2-plate mold or hot runner system.

The robot has demonstrated the concept of industry 4.0 to be capable of arranging, stacking, quality

checking and in mold placement. It is suitable for injection molding machine

under 3600T clamp force. The arm

is made of aviation used magnesium alloy, which is

light and can maintain its rigid strength to make the robot running rapidly.

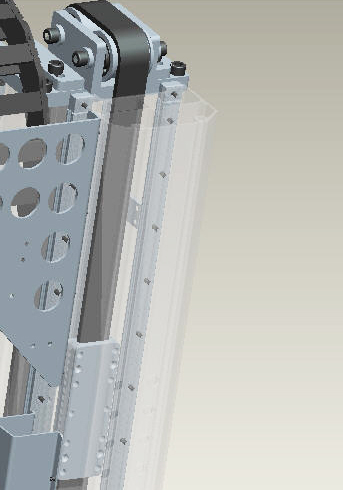

Double wheel synchronous belt mechanical linkage

Moreover, Shini hand controller integrated with different languages to easily converge seamlessly with other countries. The robot end has optional AC or BC servo axis which could meet the most complicated embedded and stacked tasks. It also can complete multi-DOF movement to remove products and choose optimal path for serving product post-processing. Furthermore, Shini robot has its own unique flip cylinder design, using rack and pinion to achieve smooth and accurate flipping. Its synchronous belt mechanical linkage is supported by two wheels which can achieve great force balance and high load capacity.

All above features have made Shini robots perform excellently and obtain reputation in automation industry. Although we are a newcomer inNorth Americamarket, we have the confidence to capture a significant market shares in the future with Shini brand.Experience Sharing

- Shini sLink Protocol Solution Applied in Injection Molding System

- Application of Central Conveying System

- Material Processing System used in Electronics Industry

If you want to read other articles, back to2016 Quarter 1 Issue 26.