Special Reports

Cold Mold Sweat Dehumidifier

In the plastic injection molding cycle,

while chilling water being introduced, there will be moisture condensation on

mould’s surface, since the surface temperature of mould is lower than the

surrounding air temperature after being cooled by chilling water. Moisture

condensation may severely affect products’ quality and production efficiency.

The most simple and effective way to avoid moisture condensation is to make the

temperature of air surround the mould’s surface lower than the one of mould’s

surface. Using dehumidifier can achieve this aim. The following are

instructions of several main industrial dehumidifiers on market.

Types of Industrial Dehumidifiers

According to working principles, it can be

sorted into the following types: Cold Mold Sweat Dehumidifier, Honeycomb Rotor

Dehumidifier, Compressed Air Dehumidifier, Lithium Bromide Adsorption Type

Liquid Dehumidifier.

Dehumidifier with refrigerating system

achieves the effect of dehumidification by cooling the air to lower dew-point

temperature and separate out moisture from air. It can be applied to extremely

wide fields and is easy and simple to operate. Honeycomb rotor dehumidifier

achieves the effect of dehumidification by using its molecular sieve and silica

gel to adsorb moisture in air, the dehumidification effect of this type is

good. Its dew-point temperature can reach to lower than

Above all being said, frozen type and

honeycomb rotor are the main humidifying types. The following will simply

introduce.

Working Principles

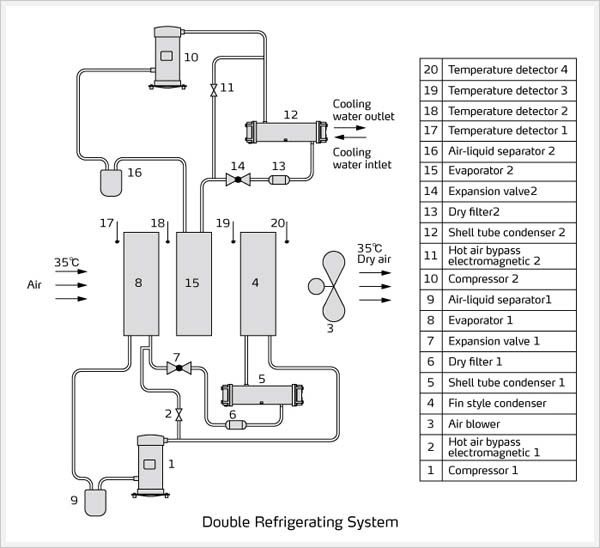

One working principle of Cold Mold Sweat

Dehumidifier is to apply double refrigerating system. Air exchanges heat with

refrigerant through evaporator 1 to take away some heat. Next, the air goes

through evaporator 2 to further exchanging heat with refrigerant to lower

temperature to the required dew-point temperature. During this procedure, moisture in air

dissolves out and then the air absorbs heat while getting through the fin style

condenser to raise the air temperature. Finally, the air blower gets the air to

appointed place.

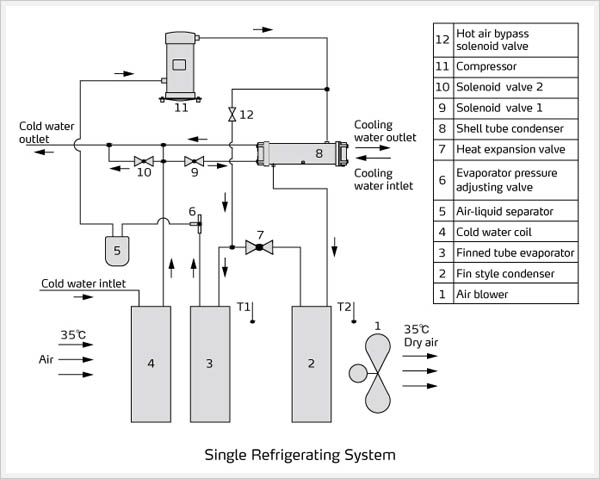

Another working principle of Cold Mold

Sweat Dehumidifier is to apply combination of single refrigerating system and

cold water coil. Air gets initial cooling by exchanging heat with chilling

water in the cold water coil to release some heat. Next, the temperature of air

will decrease continuously to meet the required dew-point temperature by

exchanging heat with refrigerant through evaporator. Then, the condenser gets

air temperature up. Finally, the air blower gets the air to appointed place.

Comparison of systems

Dehumidifier with refrigerating system of

different working principles has their own advantages and disadvantages.

Dehumidifier with double refrigerating system doesn’t require external cold water

machine to offer chilling water and can finish the whole dehumidifying process

alone. Besides, its internal structure of pipes is simple and it doesn’t

require insulation treatment toward its system of water pipes as well as can

avoid leakage. Cold Mold Sweat Dehumidifier SMD-R, which was currently

developed by Shini, is the one using double refrigerating system.

Cold sweat dehumidifier of applying

combination of single refrigerating system and cold water coil has advantage of

small temperature fluctuation, since it cool air temperature by chilling water.

If a cooling-water machine is available in factory, the machine cost of this

dehumidifier is competitive, since it has only one refrigerating system.

Otherwise, the cost may raise quite a lot. The pipeline of water system and

operation are more complicated, since it adjusts its cooling capacity by

controlling water flow through cold water coil by solenoid valve.

Above all being said, choice of different

types of dehumidifiers should depend on clients’ conditions so as to make full

use of dehumidifiers.

Application

Shini Cold Mold Sweat Dehumidifier SCMD-R-W

Series is mainly applied in plastic molding, especially suitable for PET

preform injection. Condensation trouble, which occurs when using cold water to

shorten molding cycle, affects products’ quality and production efficiency as

well as corrodes moulds’ surfaces and then brings environmental pollution. However, this

dehumidifier using refrigerating system to dehumidify can keep a low dew-point

temperature reach to about

Special Reports

- Starve Feeding

- The Principle and Application of Industrial Air Chiller

- Temperature Control in Hot Runner System——Heaters

- New Brand Image Shines at CHINAPLAS 2013

- About CHINAPLAS 2013 of Shini-Syncro Extrusion

If you want to read other articles, back to2013 Quarter 3 Issue 16.