New Product Launch

Automatic KN95 Mask Machine

SMKS-KN95

Features

1.PLC control, servo drive, with automatic counter.

2.Automatic tension control of raw materials; Ensure the balance of raw material tension.

3.Photoelectric detection of raw materials to avoid mistakes and reduce waste.

4.From loading and unloading to roll cutting forming, it can be completed in one time with high automation.

5.The machine has simple adjustment device that ensures convenient material changeover, stable performance and high efficiency.

6.It can quickly change the mold at any time to produce different shapes of folding mask body.

7.The whole machine is made of aluminium alloy structure, beautiful, solid and rust free.

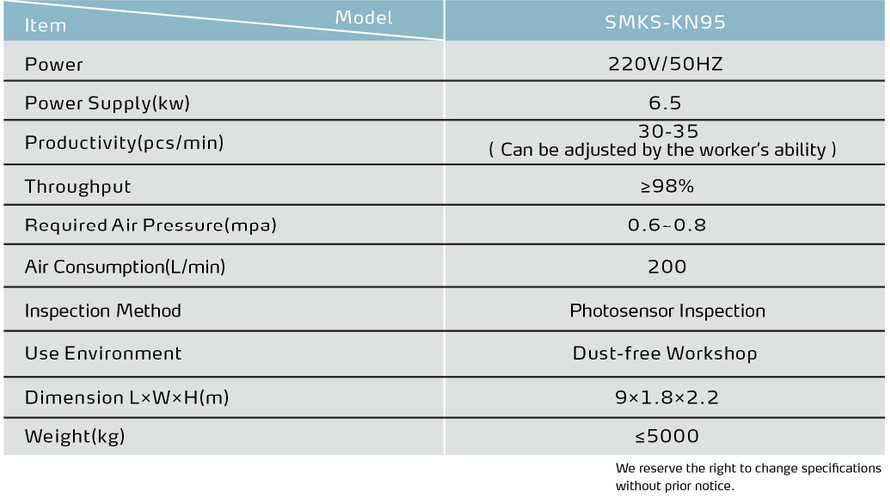

Specifications

Application

The machine is fully automatic equipment and is for making folding type face mask (typically KN95 face mask). To make KN95 face masks, different rolls of materials and rolled nose strip are mounted and fed in layers through the machine, then being welded together by ultrasonic welding unit with teeth mold. Then ear-loops are fed, cut to fixed length and welded by ultrasound ear-loop welding unit, and then the face masks are folded in half and sealed partially by another ultrasonic welding unit. After all above, it is cut to the shape and stripped away the off-cut. Then the finished KN95 face masks are conveyed to the end of the machine.

New Product Launch

- "Regular" Series SG-70150B

- KN95 Mask Blank Making Machine

- Automatic Two-Line Face Mask Machine

- Full-automatic 3-ply Disposable Face Mask Pad Machine

If you want to read other articles, back to2020 Quarter 3 Issue 40.