New Product Launch

KN95 Mask Blank Making Machine

Features

1.High stability and low down time. Robust mechanical structure and rustless finish.

2.Automatic production with PLC programmed control and servo driving system.

3.With material detection sensor to avoid material wastage and NG products.

Workflow

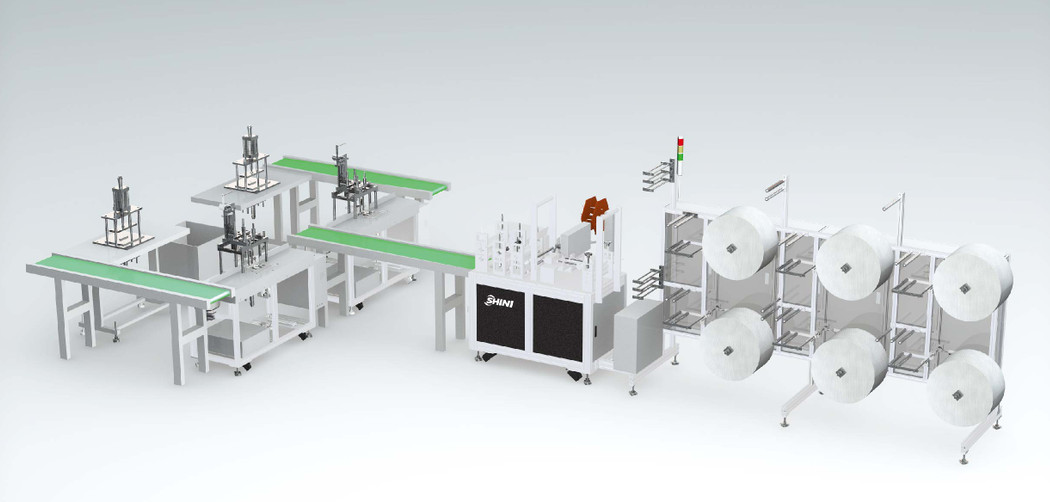

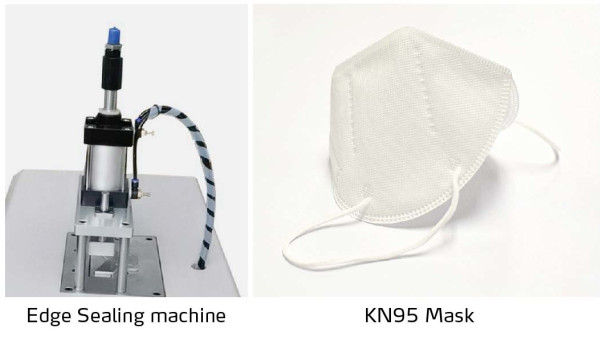

This machine is for making KN95 face mask which will feed the rolled fabrics of different layers/materials and insert the nose bridge bar automatically first, then use roller welding die with ultrasound welding horn to bind different layers of materials and cut out the main piece with roller cutter. After the main peice is formed, our SABW-KN95 (KN95 semi-automatic band welding machine) and SMES-KN95 (KN95 semi-automatic edge sealing maching) are used to weld the ear bands on the main piece and seal the edge.

Standard equipment set includes: SMKS-KN95-A*1+SMES-KN95*2+SABW-KN95*2.

Conveying belt(option):SCI-400W-2000L*3(adjustable H=700~1000mm)

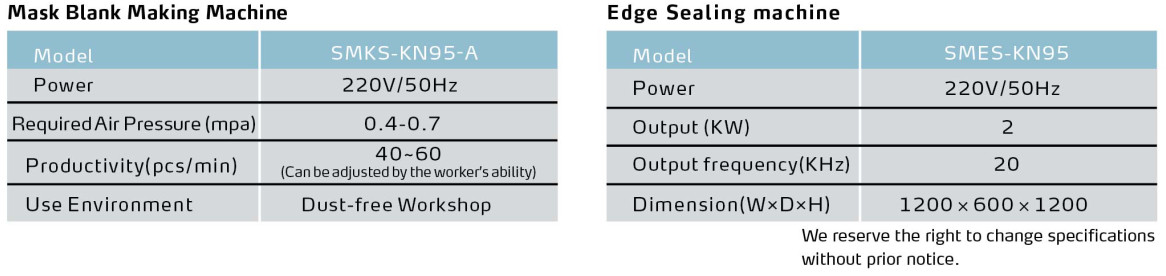

Specifications

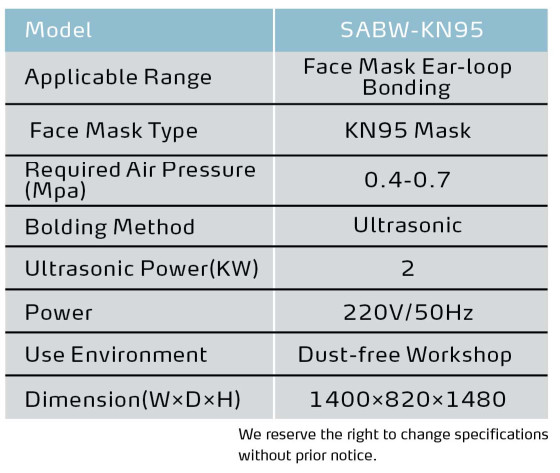

Semi-automatic Face Mask Ear-loop Machine

Workflow

1.Manually insert the face mask without ear loops into the machine

2.Press the start button

3.Bond one side of the face mask

4.Bond another side of the face mask after rotating it

Specifications

New Product Launch

- "Regular" Series SG-70150B

- Automatic KN95 Mask Machine

- Automatic Two-Line Face Mask Machine

- Full-automatic 3-ply Disposable Face Mask Pad Machine

If you want to read other articles, back to2020 Quarter 3 Issue 40.