Special Reports

2021 Quarter 4 Issue 45

Shini New Product – Mould Temp. Controllers STM-1220WD

Features

Man-machine Interaction / Quick and Flexible

As a new generation of ShiniMould Temperature Controllers, the STM-1220WD series realizes the dual-stage independent temperature control with a touch display. The operation becomes faster and more convenient than before.

Compared with the push-button control panel of traditional machines, this 7-inch touch screen realizes the visualized and precise control so that the operators of enterprises can learn how to operate the machine and start it quickly without spending extra time. It avoids complicated operations in previous works and reduces the probability of misoperation, greatly improving the operating efficiency! Quick response is only a necessary basis. In equipment layout and site planning, many enterprises are limited by various factors when planning the production line, such as equipment size, plant area, hydropower pipeline, etc. As a result, they paid no attention to plenty of the space above—the designers of the ShiniMould temperature controller group realized and redesigned it. The vertical Mould Temperature Controller they adopted occupies less space and has a higher utilization rate, flexibly suitable for various plant solutions.

STM-1220WD with SSR solid-state heating output and high-efficiency water circulating pump can meet the temperature demand up to 120 ℃, and the temp. control accuracy reaches ± 0.5 ℃.

Facing the test / Reliable and Comprehensive

To achieve efficient production, this series of Mould Temperature Controller also has auto air exhaust and auto water refilling functions to help manufacturers realize automatic production.

Most importantly, this mould temperature controller can control the mould temperature independently, thus providing two different mould temperatures to meet the flexible demands of the molding process. For example, this series of models is particularly suitable for independent temperature control of the two-plate mould and the front and rear mould. Through flexible adjustment of the front and rear mould temperature, it not only can ensure stable quality but also can reduce the adjustment difficulty, making it easier to put into production.

When working under a high impact and high vibration environment, the solid-state relay has neither input "coil" and nor mechanical contact. These excellent characteristics give long service life of the STM-1220WD and higher reliability! This series of mould temperature controllers have various built-in safety displayers and alarm devices, such as reverse protector, pump overload protector, overheat protector, and high and low voltage protector, which can always guarantee your production.

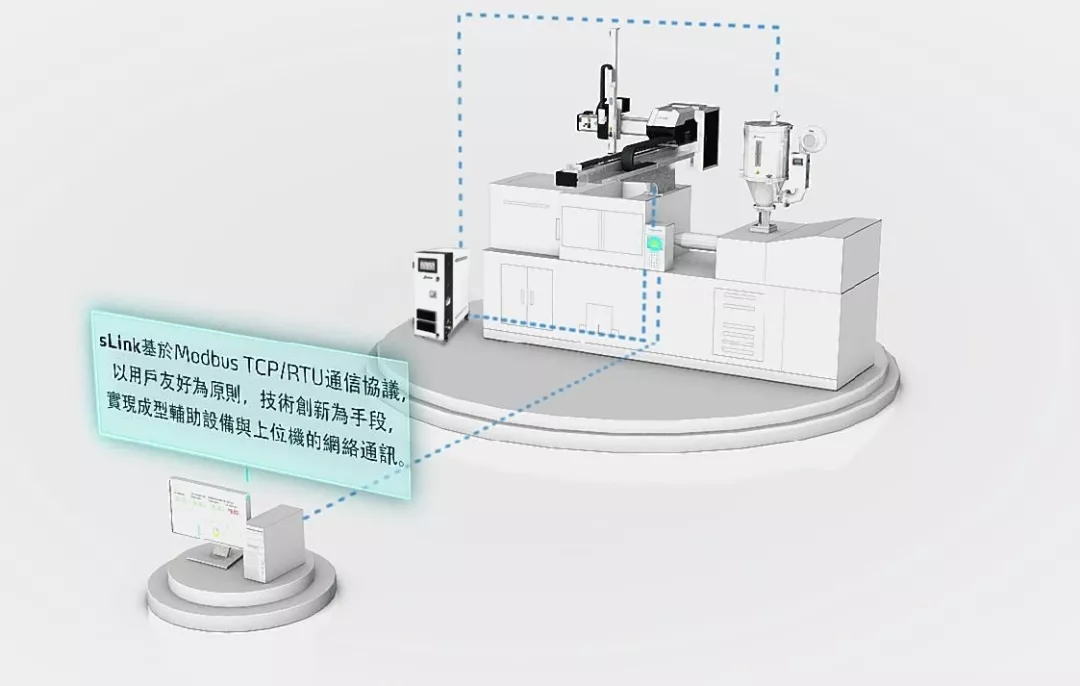

Interconnection and Sharing

If the above mentions are only the pursuits of the equipment's performances, the interconnection undoubtedly reflects the Internet of Everything and data sharing in the era of intelligent industry. Shini designed the standard RS485 communication interface for the double-stage water heater, which helps enterprises realize data sharing, equipment interconnection, and centralized monitoring of various equipment parameters. This may be just a simple communication interface, but Shini is willing to build the data bridge for all enterprises, which helps more enterprises move towards intelligent production. The most important task of manufacturing is production, leading, and developing; As Shini, the most important thing is to keep moving forward as ever and launch products that can be tested by the market and recognized by the customer.

Special Reports

If you want to read other articles, back to2021 Quarter 4 Issue 45.