Experience Sharing

2022 Quarter 1 Issue 46

Automation in electric tools industry

Electric tool is a kind of mechanized tool driven by motor or electromagnet and served as tools of specific purposes through transmission mechanism. It can be divided into metal cutting electric tools, grinding electric tools, assembly electric tools and railway electric tools. The hardware electric tools commonly used in daily life mainly include electric drill, electric grinder, electric wrench and electric screwdriver, electric hammer and impact electric drill, concrete vibrator, electric planer and so on. As one of the common application tools, electric tools can be seen everywhere and have a wide range of applications, including machinery industry, building decoration, landscaping, wood processing, metal processing and so on. They play an indispensable role in social and economic development. The use of automatic equipment in electric tools production lines can effectively control the cost, improve the production efficiency, ensure the product quality and improve the overall competitiveness of the enterprise.

An electromechanical company in Guangdong province, which mainly manufactures and sells electric tools, household appliances, hardware tools, air compressors, pneumatic tools, gardening tools, barbecue ovens, range hoods, environmental protection household appliances, various mechanical equipment and electronic components…, started working with Shini from 2021 in production automation has used many Shini ST3/ST5 robots for fully automatic injection molding. After the equipment is put into use, the stable and efficient operation satisfies the customer with consistent output, higher productivity and improved quality.

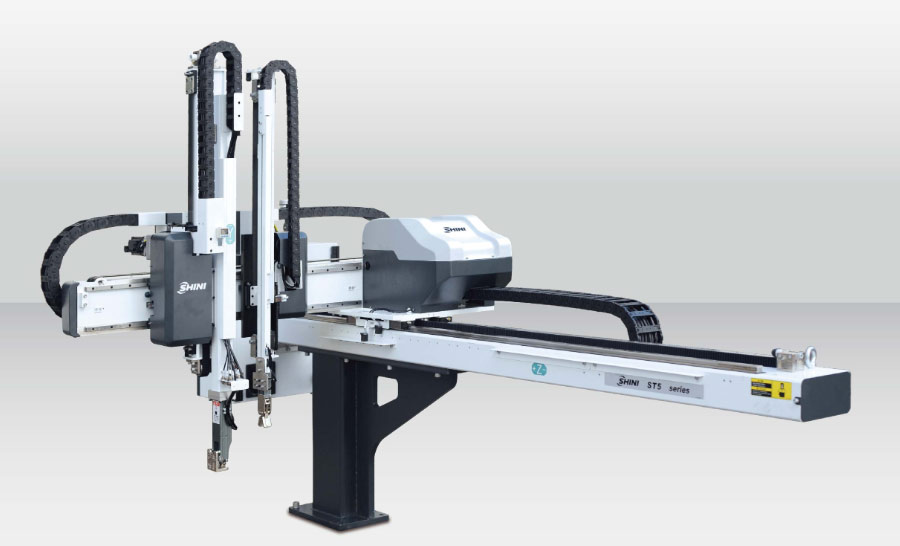

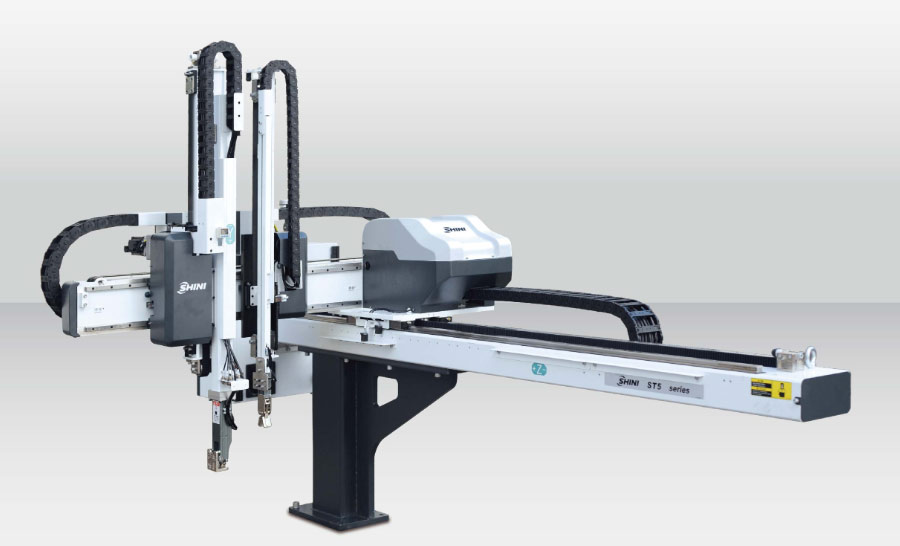

The ST3/ST5 series robot is designed to remove products/sprue from injection molding machine. Customers can choose single/dual arm(s) robot for use with 2-plate mold, 3-plate mold or hot runner system. The robots have demonstrated the concept of industry 4.0 and capable of aligning, stacking, quality checking and insert placing. It is suitable for injection molding machine under 3600T clamp force.

An electromechanical company in Guangdong province, which mainly manufactures and sells electric tools, household appliances, hardware tools, air compressors, pneumatic tools, gardening tools, barbecue ovens, range hoods, environmental protection household appliances, various mechanical equipment and electronic components…, started working with Shini from 2021 in production automation has used many Shini ST3/ST5 robots for fully automatic injection molding. After the equipment is put into use, the stable and efficient operation satisfies the customer with consistent output, higher productivity and improved quality.

The ST3/ST5 series robot is designed to remove products/sprue from injection molding machine. Customers can choose single/dual arm(s) robot for use with 2-plate mold, 3-plate mold or hot runner system. The robots have demonstrated the concept of industry 4.0 and capable of aligning, stacking, quality checking and insert placing. It is suitable for injection molding machine under 3600T clamp force.

ST5 servo driven robot appearance

Experience Sharing

- A Step Towards the "New" Progress with Mutual Trust

- The Application of Plastic Molding Auxiliary Equipment in Auto Parts Industry

- Application of Large Granulator in Plastic Recycling Industry

- Case Sharing – The Application of Central Material Processing System in Auto Parts Industry

If you want to read other articles, back to2022 Quarter 1 Issue 46.